ENGLISH

17

is

reached

before

pump

has

primed.

Measure

liquid

temperature

and

modify

alarm

and

stop

trips

settings

accordingly.

Theoritically

the

pump

could

prime

up

to

8

meters

but

lifting

height

will

be

limited

to

6

meters

to

take

suction

line

head

losses

into

account.

Check

that

the

system

available

NPSH

(NPSH

A

)

is

always

higher

than

the

required

NPSH

(NPSH

R

)

of

pump

when

fluid

level

is

at

its

lower

point.

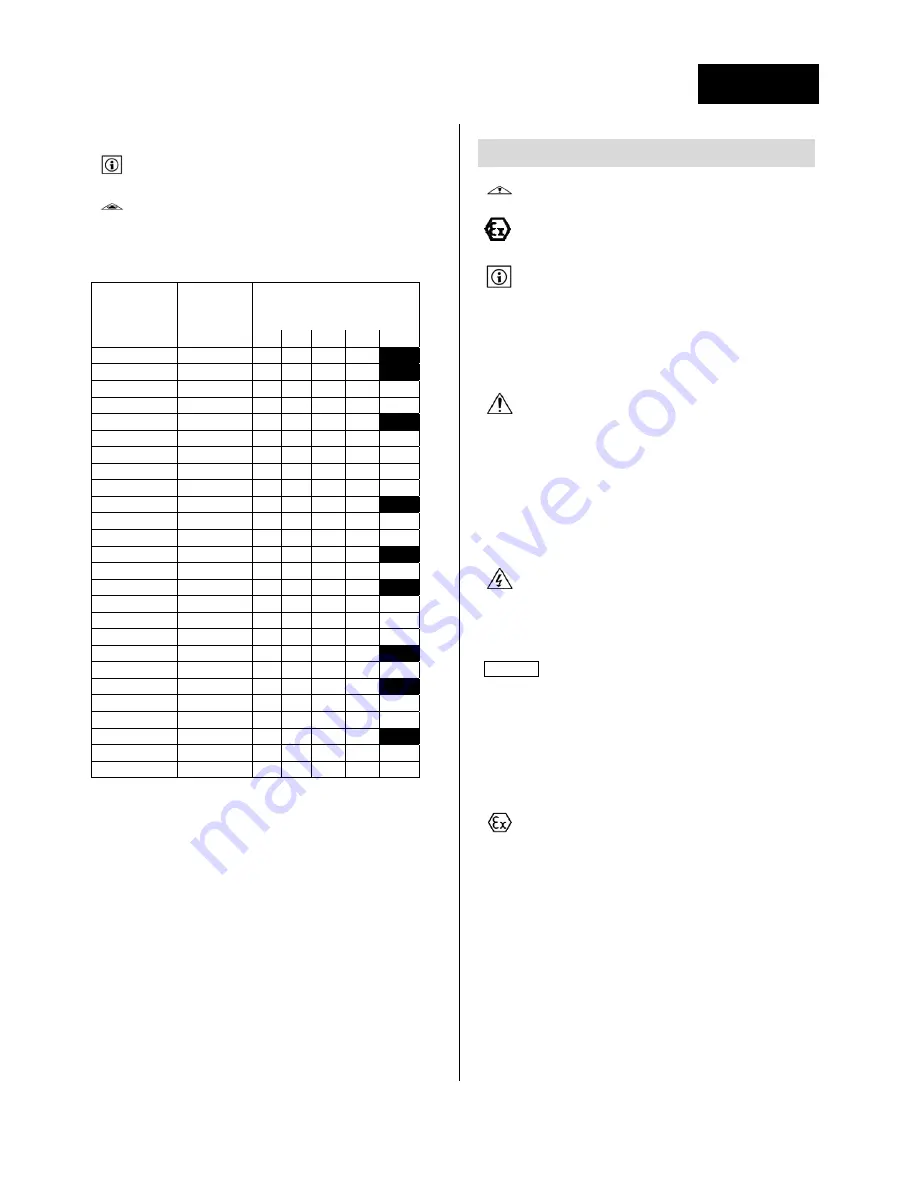

Theoretical

priming

times

(Nominal

Dia

of

pipe

=

pump

nominal

dia)

:

Pump

size

Pump

speed

Priming

time

in

seconds

vs

suction

lift

height.

[Tt]

2

3

4

5

6

S40

2900

21

47

78

135

S41

2900

27

57

93

153

S45

2900

12

22

35

47

62

S46

2900

5

8

13

23

34

S50

2900

17

29

46

83

S51

2900

19

34

55

87

155

S60

2900

19

29

42

56

77

S61

2900

10

15

21

29

41

S63

2900

7

10

14

19

33

S65

1450

30

58

83

186

S68

2900

9

14

19

26

38

S80(

‐

2)

2900

36

49

62

74

95

S80

2900

21

53

95

132

S83

2900

14

20

26

31

39

S85

1450

32

63

100

152

S88

2900

4

7

11

18

26

S88

(210)

2900

5

8

11

15

20

S100

2900

19

30

38

45

54

S105

1450

38

69

110

167

S105

2300

9

13

17

21

25

S105

T114

1450

30

62

110

189

S108

2900

10

14

18

22

27

S120

1450

10

18

31

50

95

S150

1450

33

71

117

176

S160

1450

15

26

41

63

93

S170

950

28

51

85

129

181

Priming

time

depends

on

lifting

height,

length

of

the

suction

line,

inner

diameter

of

suction

pipe

and

specific

gravity

of

the

fluid.

It

will

be

necessary

to

apply

correction

factors

to

know

priming

time

:

Tt

=

table

with

Ha

=

Hg

x

d

Ta

=

Tt

x

L/Hg

x

(DT/DN)²

With

:

Tt

:

theoretical

priming

time

Ha

:

suction

height

with

specific

gravity

correction

factor

d

:

Specific

gravity

of

fluid

L

:

total

length

of

suction

line

DT

:

inner

diameter

of

suction

pipe

DN

:

pump

suction

flange

nominal

diameter

9

MAINTENANCE

9.1

GENERAL

INFORMATION

Only

properly

trained

and

skilled

staff

should

undertake

maintenance

operations.

Only

authorized

personnel

should

undertake

maintenance

on

ATEX

certified

equipments.

Make

sure

to

avoid

creation

of

explosion

hazard

while

proceeding

to

maintenance

in

a

ATEX

zone.

All

technical

documents

delivered

with

the

pump

should

be

known

and

should

be

available

near

the

pump.

The

maintenance

crew

should

be

informed

about

the

risks

linked

to

the

use

of

the

pump

and

to

the

pumped

fluids

before

they

can

start

working

on

the

equipment

(dangerous

products,

fluid

and

pump

temperature,

pressurized

parts,

…).

They

should

be

equipped

with

all

appropriated

individual

safety

protections

(glasses,

gloves,

…)

and

should

respect

local

industrial

and

security

rules.

Pump

contains

a

part

of

pumped

fluid

even

when

it

is

at

a

standstill.

Drain

and

flush

pump

casing

with

care

before

starting

pump

disassembly.

Appropriate

lifting

devices

should

be

available

to

help

personnel

moving

heavy

loads.

The

maintenance

area

must

be

clearly

identified.

Install

warning

boards

with

the

words

«

WARNING

:

machine

under

repair

!

»

on

the

pump

and

on

the

control

cabinet.

Any

work

on

the

machine

must

be

performed

when

pump

is

stopped.

Prior

to

any

maintenance

or

repair

work

the

motor

should

be

electrically

isolated

and

secured

against

uncontrolled

start.

Lock

the

main

switch

open

and

disconnect

circuit

breaker.

Withdraw

the

fuses

if

any.

WARNING

:

electrical

equipments

that

must

be

powered

on

during

the

maintenance

work

or

pressurized

equipments

must

be

clearly

identified.

End

of

maintenance

operations

:

all

protective

parts

that

were

removed

before

maintenance

should

be

reinstalled

and

all

security

devices

should

be

reactivated.

Pump

surrounding

area

should

be

cleaned.

9.2

MAINTENANCE

AND

PERIODIC

INSPECTIONS

SCHEDULE

It

is

recommended

to

build

up

a

maintenance

and

inspection

plan

to

ensure

a

reliable

use

of

pump

and

to

reduce

malfunctions

hazards.

Following

check

points

should

be

included

in

this

maintenance

plan

:

Check

state

and

working

of

securities

and

auxiliary

systems,

Check

and

adjust

gland

packing

(if

any)

for

visible

leakage,

Check

for

any

leaks

from

pump

gaskets

and

flanges

seals,

Check

lubricant

level

and

aspect

of

oil

(oil

lubricated

bearings)

in

bearing

bracket,

Check

running

time

and

replacement

frequency

of

lubricants

/

ball

bearings,

Check

the

bearing

bracket

housing

surface

temperature

on

ball

bearings

area,

Check

dirt

and

dust

is

removed

from

pump

and

motor

,

Check

coupling

alignment

(depending

on

pump

variant),

Check

if

there

is

unusual

noises

(cavitations,

hissing,

purring,

…)

or

excessive

vibrations.

Содержание S series

Страница 2: ...S INSTALLATION ET MISE EN SERVICE N M S n 4071640 Ed 5 10 13 FRAN AIS...

Страница 23: ...FRAN AIS 23...

Страница 24: ...24...

Страница 25: ...S INSTALLATION AND OPERATING INSTRUCTIONS N M S n 4071640 Ed 5 10 13 ENGLISH...

Страница 26: ...2...

Страница 48: ...24...