̶

12

̶

3.5. Checking bolts and nuts for their tightness

Re-tighten bolts and nuts in each section after each operation and once a week.

Bolts and nuts are likely to become loose due to vibration of the machine body.

If it is operated with the bolts and/or nuts losened, malfunction and damage to the machine

may result.

In particular, be sure to check bolts and nuts securing tamping shoe before starting operation.

Since crankcase and its related members are made of alumi-

num, be careful not to over-tighten them.

•

CAUTION

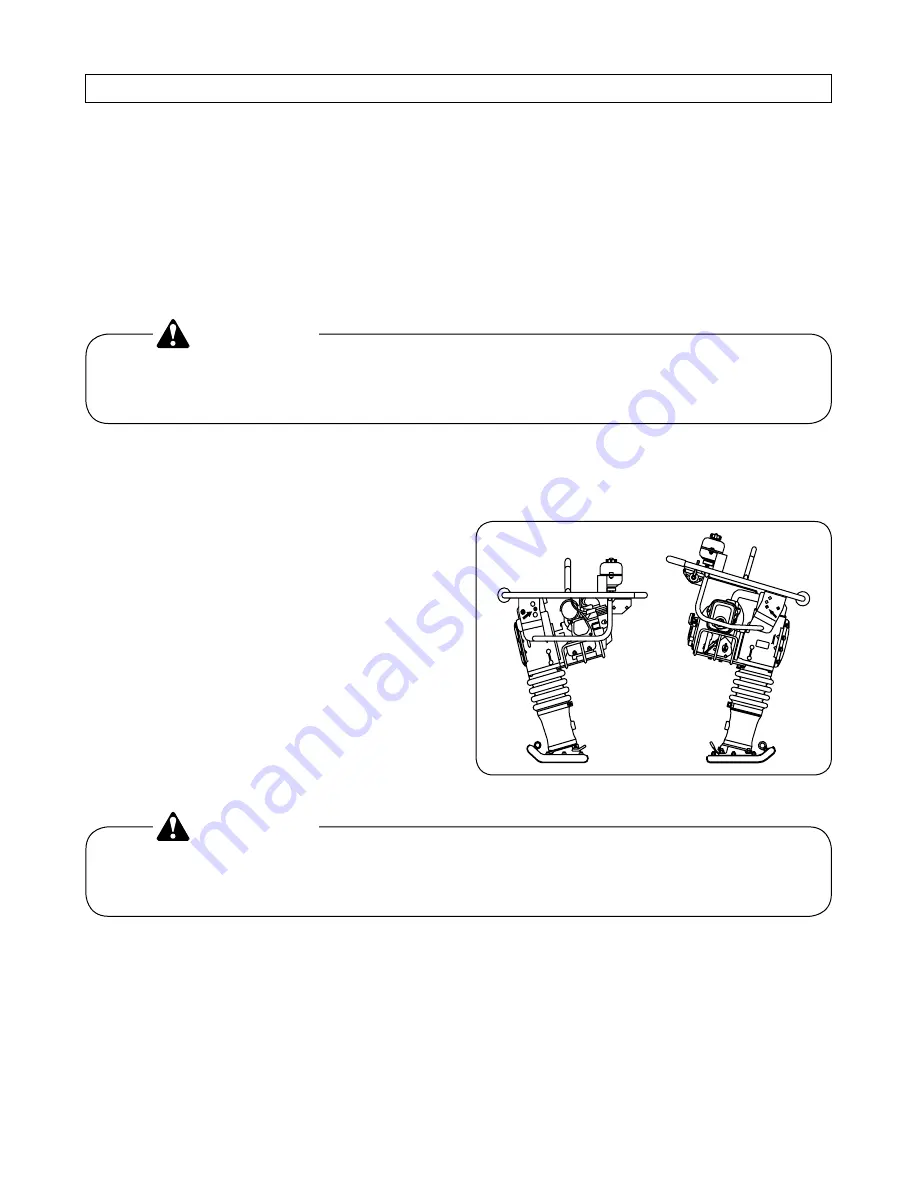

3.6. Handle height adjustment

Handle height can be adjusted in two(2)

steps to meet the operator's height.

It can easily be adjusted by relocating han-

dle counting bolts.

3. Inspection before operation

Although there are three (3) holes in the handle, do not use

the uppermost hole.

•

CAUTION