XL-AS20016BM-en-US Rev A · 2015-05-28 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Operation Instructions

13

PULL ARM

HANDLE

LOCK PINS

ENGAGED

ENGAGED POSITION

NOTCH 1

NOTCH 2

Figure 21

Figure 22

Figure 20

10. Slider Repositioning Instructions

1. With the vehicle on a level surface, set the tractor and

trailer brakes and locate the slider QWIK RELEASE

®

pull

arm handle

(Figure 20)

, or air release control valve.

2. To reposition the slider, remove the manual stop bar

and relocate to desired location – rearward of slide box

if moving rearward, or forward of slide box if moving

forward

(Figure 20)

.

If repositioning the slider forward, remove the manual

stop bar and relocate directly behind slide box after the

slider is moved to final position.

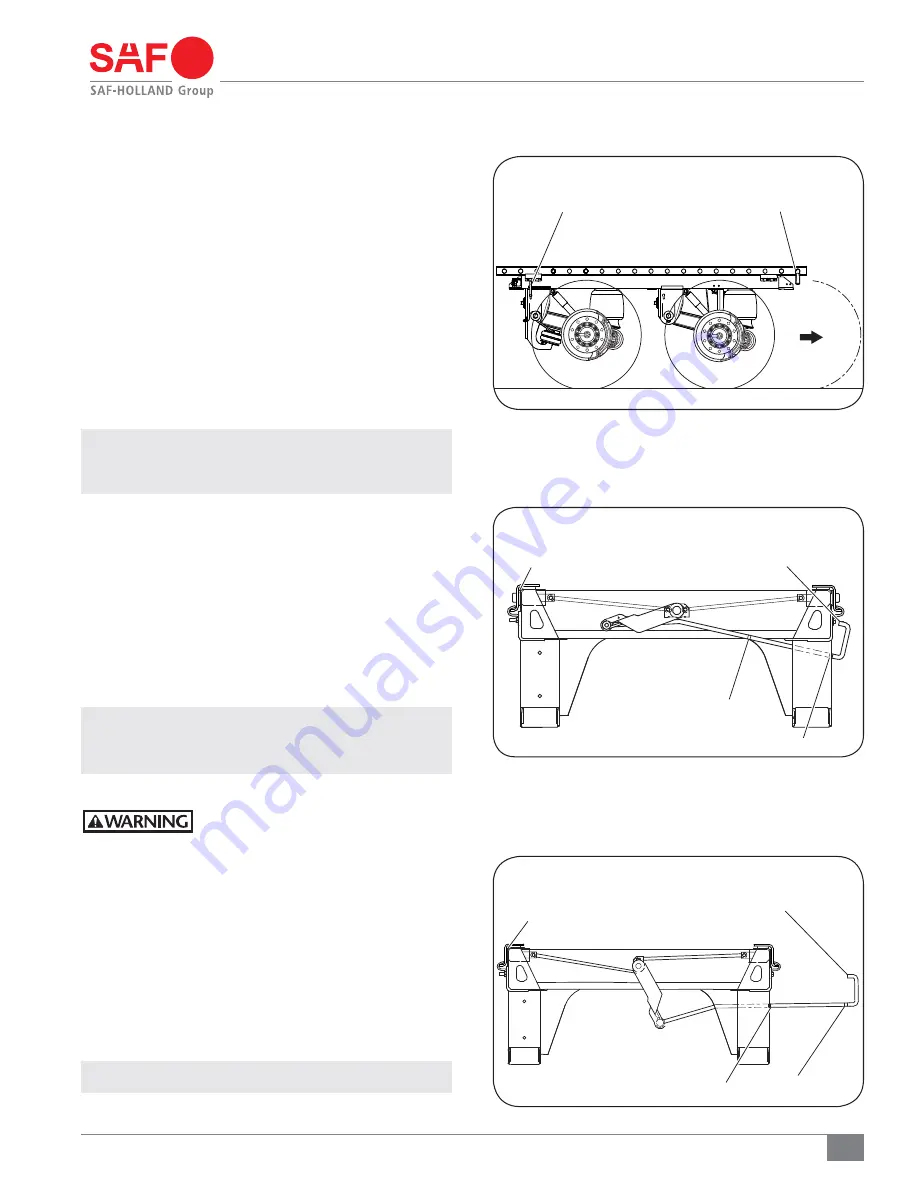

3. Lift and pull the QWIK RELEASE

®

pull arm handle from

the engaged position

(Notch 1 - Figure 21)

to the

disengaged position

(Notch 2 - Figure 22)

.

NOTE:

If your slider is equipped with an air release pin

mechanism, pull the air release control valve knob

to disengage the lock pins.

4. Visually check to ensure the lock pins are in the disengaged

position, and that the QWIK RELEASE

®

pull arm handle is

locked

(Notch 2 - Figure 22)

.

When lock pins have properly disengaged, proceed

to Step 6.

If lock pins fail to disengage, proceed to Step 5.

5. If the QWIK RELEASE

®

pull handle is in the notch 2

position but the lock pins fail to retract and are still

in the engaged position, the QWIK RELEASE

®

pull

arm is in an armed, ready to unlock position.

NOTE:

The QWIK RELEASE

®

torsion spring will

automatically retract the lock pins when

the pressure on the lock pins is released.

a. Release the tractor brakes.

Failure to verify the area is clear of

others before moving the vehicle could

result in death or serious injury.

b. Gently rock the tractor and trailer fore and aft while

listening for the lock pins to disengage.

c. After the “metallic clang” of the lock pins disengaging

is heard, reset the tractor brakes, and visually verify

that the lock pins have been properly disengaged.

6. When the lock pins have disengaged, release tractor

brakes and slowly reposition the tractor until the slide

box contacts the manual stop bar

(Figure 20)

.

7. Set the tractor brakes.

NOTE:

Trailer parking brakes should still be engaged.

MANUAL

STOP BAR

QWIK RELEASE

®

PULL ARM HANDLE

PULL ARM

HANDLE

DISENGAGED POSITION

NOTCH 1

NOTCH 2

LOCK PINS

DIS-ENGAGED

CBX 40 ILLUSTRATED