17

A

A

B

B

A-A

B-B

1

2

3

3

4

EN

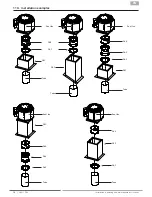

14.2. Impeller installation with Taperlock clamping bush

1. Clean all bare surfaces (mating surfaces of

the clamping bushings and motor shaft).

2. Insert the clamping bush (1) into the hub (2)

and bring the holes into alignment.

3. Loosely lubricate the threaded pins (3) and

screw in - do not tighten yet.

4. Push the impeller onto the shaft with the

clamping sleeve, align it in the axial position

and tighten the threaded pins evenly on both

sides. Observe the tightening torque accor-

ding to table.

Assembly

The impeller is connected by means of the clamping bush to the shaft end of the drive motor.

Disassembly

1. Loosen all the threaded studs (3) and screw

them out completely. Lubricate a threaded

pin and screw it into the disassembly hole

(4).

2. Tighten the threaded pin until the clamping

bush (1) is released from the hub (2).

3. The impeller can be removed.

Bushing size

Torque table

Bushing size

1210

2012

2517

Screw tightening torque with feather

(Nm)

17

26

41

Screw tightening torque without feather

(Nm)

20

31

48

Number of screws

2

2

2

Technical data

Commissioning (after replacement)

■

Remove any remaining installation material and foreign objects from the impeller and suction area.

■

Check direction of rotation (direction of rotation arrow on the impeller base disc).

■

During initial commissioning, the entire unit must be checked for mechanical vibrations. If necessary, re-balancing

must be carried out.

■

Pay attention to a quiet operation, without vibrations.

www.ruck.eu |

Содержание DVN***D.F4 Series

Страница 19: ...19 EN Notes www ruck eu...