PLASTIC MOULDINGS

V

IA DELL

’

ARTIGIANATO

,

6

•

61026

LUNANO

(PU)

•

I

TALY

T

EL

.

+39

0722

722801

•

F

AX

+39

0722

70599

•

W

EB

:

www.rototec.it

E-

:

•

PEC

VAT

and TAX

CODE

01476690415

•

C

OMPANY

C

APITAL

.

120.000,00

CCIAA

(C

HAMBER OF

C

OMMERCE

R

EG

.

N.)

12602

P

ESARO

DEPURO ONE Use and Maintenance Manual, Rev. 00 of 27/01/2016

Page 6 of 13

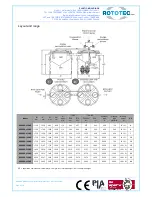

6. INSTALLATION

Tanks

•

Before installing the tanks, make sure that all the components are present: primary sedimentation tank and

oxidation tank with recirculation. Both tanks are fitted with biogas vents. The oxidation tank has a pair of diffuser

pipes installed internally. Two blowers and an electric blower control panel are supplied in 3 separate boxes.

•

The tank installation sequence is that indicated in the installation diagram (see Paragraph 5)

•

It’s advisable to install the tanks making up the plant no more than one metre apart. The distance between the

tanks can be greater providing that the connecting pipe has a gradient of not less than 2%.

•

When installing the tanks, the pipes should always have a gradient of 2-3%.

•

Connect the sludge recirculation pipe between the two tanks.

•

To prevent bad smells from being generated during plant operation, always connect the biogas vents of both

tanks to a suitable pipe discharging to atmosphere, preferably on the roof of the building.

Install the tanks scrupulously following the installation instructions supplied by ROTOTEC (Paragraph 9). DEPURO

ONE plants must always be installed underground.

Blowers/compressors

Diaphragm type air compressors used in air-lift sludge return systems and for developing an

aeration system necessary for the digestive processes of the aerobic bacteria, making use of the

electromagnetic vibration of an actuator rod supported by synthetic rubber diaphragms.

The blowers, together with the electric control panel, must be installed in an appropriate covered control room prepared

by qualified personnel. The room must have the following characteristics:

•

it must be positioned above ground at a maximum distance of 10 m from the treatment plant;

•

the base must be solid, flat and located above the level of the tank in order to avoid a backflow of sludge in the

case of an interruption in the air supply;

•

it must have sufficient air changes to prevent the blower from overheating and to allow the entry of the air

required to pump into the tanks;

•

the internal environment must be free of corrosive gases and must not be exposed to vibration.

Model

Voltage

V

Frequency

Hz

Watt

W

Amps

A

Capacity

l/min

Rated

Pressure bar

Noise level

dB

Weight

Kg

Length

mm

Width

mm

Height

mm

HP 40

220

50

31

0,32

40

0,130

< 39

4,9

260

190

190

HP 60

220

50

61

0,6

70

0,150

< 48

6,9

205

172

215

HP 80

220

50

91

1,00

88

0,150

< 57

7

205

172

215

HP 150

220

50

152

1,9

148

0,200

< 53

13

214

212

187

HP 200

220

50

186

1,7

200

0,200

< 48

11,9

272

226

247