PLASTIC MOULDINGS

V

IA DELL

’

ARTIGIANATO

,

6

•

61026

LUNANO

(PU)

•

I

TALY

T

EL

.

+39

0722

722801

•

F

AX

+39

0722

70599

•

W

EB

:

www.rototec.it

E-

:

•

PEC

VAT

and TAX

CODE

01476690415

•

C

OMPANY

C

APITAL

.

120.000,00

CCIAA

(C

HAMBER OF

C

OMMERCE

R

EG

.

N.)

12602

P

ESARO

DEPURO ONE Use and Maintenance Manual, Rev. 00 of 27/01/2016

Page 4 of 13

OUTLET

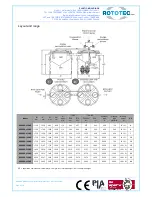

INSTALLATION DIAGRAM

5. DEPURO ONE

The DEPURO ONE treatment plant inside the two

tanks exploits and optimises these processes in a

controlled environment. This it does in a manner that

ensures that the principal reference parameters BOD

5

,

COD, SS (Suspended Solids) and N

tot

(Total Nitrogen)

at the discharge are within the limits set by current

standards.

The treatment plant itself is made up of the following sections:

-

Primary sedimentation tank: is a true Imhoff type biological tank consisting of two overlapping and hydraulically

communicating compartments. In the upper compartment the sedimentable solids drop to the bottom of the

sedimentation chamber by gravity. The chamber is suitably inclined to allow the sludge to pass into the lower

compartment. Here the sludge accumulates and is partially digested by anaerobic bacterial micro flora which

develops and remains active.

In the same way, the components with a specific weight lower than that of water (e.g. oils and greases, foam,...)

separate from the effluent and accumulate in the upper compartment of the tank.

The surplus sludge recirculated by the oxidation treatment plant installed downstream also accumulate in this first

tank.

The physical process of gravity separation, combined with the cold anaerobic digestion processes that take place in

this first tank, result in an over 50% reduction of the solid and organic component in the effluent itself.

-

Oxidation treatment plant with recirculation: this tank is also divided into two sections: the lower and larger

section provides for oxygenation of the effluent, whereas the (successive) upper section forms a stilling tank in

which the residual surplus sludge separates from the effluent, accumulates at the bottom of the tank, and is returned

to the first tank via an air-lift type recirculation system. The oxygen required to develop the aerobic reactions is made

available in dissolved form through dissolution in the liquid of the oxygen present in the atmosphere, by means of

energetic artificial aeration using suitable blowers/compressors and micro-bubble air diffusers, located on the

bottom of the tank. Complex phenomena are set up in the oxygen-rich environment of the aeration compartment.

These are chemical (chemical oxidation of the malodorous substances), physical (the jelly-like flakes of activated

sludge trap any solids that may have escaped primary treatment) and above all biological (the micro-organisms use

the dissolved organic substances to develop, transforming them into a living substance that can be separated from

the water by sedimentation). The two blowers/compressors (the oxygenation blower and the one feeding the

recirculation system) are low-energy diaphragm compressors equipped with a control panel with digital timers

to optimise the system on/off timing. This control panel also has a buzzer and a visual alarm to indicate any

malfunctions in the compressors.

1.

2.