PLASTIC MOULDINGS

V

IA DELL

’

ARTIGIANATO

,

6

•

61026

LUNANO

(PU)

•

I

TALY

T

EL

.

+39

0722

722801

•

F

AX

+39

0722

70599

•

W

EB

:

www.rototec.it

E-

:

•

PEC

VAT

and TAX

CODE

01476690415

•

C

OMPANY

C

APITAL

.

120.000,00

CCIAA

(C

HAMBER OF

C

OMMERCE

R

EG

.

N.)

12602

P

ESARO

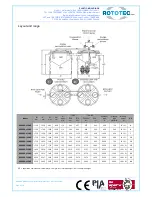

DEPURO ONE Use and Maintenance Manual, Rev. 00 of 27/01/2016

Page 12 of 13

20/30cm

5mt

60°

1

5

/2

0

c

m

Topsoil

Topsoil

WATER

1)

WATER

3)

WATER

2)

WASHED

GRAVEL 2/6

4)

WASHED

GRAVEL 2/6

5)

TOPSOIL

Washed gravel 2/6

Topsoil

Topsoil

Topsoil

Extension chamber

Topsoil

Topsoil

Topsoil

Washed gravel 2/6

Extension chamber

Washed gravel 2/6

Topsoil

Topsoil

Extension

chamber

Vent pipe

Cover

Concrete

slab

Cover

Concrete

slab

Washed gravel 2/6

Topsoil

Topsoil

Concrete slab

Topsoil

Cover

1.

EXCAVATION

1.1

Excavate a hole of suitable dimensions with a flat bottom, leaving a space of at least 20/30

cm around the tank. In the presence of heavy ground (e.g. clayey subsoil and/or groundwater) the

distance must be at least 50 cm.

Spread a 15/20cm deep layer of 2/6 washed gravel on the

bottom of the excavation to allow the tank to rest on a uniform and level base. Excavated material

must not be used as backfill. The excavation must be a minimum of 1 m from any structures.

2.

BACKFILL AND FILLING

2.1

Place

the totally empty tank

on a bed of 2/6 washed gravel spread at the bottom of the

excavation, gradually fill the tank with water and at the same time backfill with 2/6 washed gravel.

Continue with successive layers of 15/20cm, filling the tank and then backfilling with gravel. Fill the

tank to 3/4 of its capacity and backfill the last 40cm with topsoil (NOT clayey/limey material,

NOT excavated material). To prevent excessive pressure on the tank, NEVER use backfill

material with sharp edges.

N.B. For installation in more severe conditions (groundwater, clayey soils or in sloping ground),

refer to chapter 3 “Exceptional Installation”.

2.2 After the tank has been filled and the excavation suitably backfilled, gradually cover with

topsoil (NOT clayey/limey material, NOT excavated material) to a depth of 30/40cm, leaving

the inspection covers exposed. In this way, the area concerned is suitable for pedestrian traffic,

while the transit of motor vehicles within 2 m of the excavation is prohibited. N.B. To render the

site trafficable by motor vehicles, refer to chapter 4 “Trafficability”

2.3 EXTENSION INSTALLATION

If the tank is installed at a depth of 30/40cm and the site is to remain open to pedestrian traffic, it is

advisable to install the Rototec PE extension directly on the inspection holes. In the case where

the tank is installed deeper than that previously indicated, which constitutes an unfavourable

and not recommended condition, adhere scrupulously to the instructions reported in chapter 4

"Trafficability". The technician responsible for the installation will follow the instructions reported

in the two paragraphs according to the installation depth.

2.4 PUMP/BIOGAS VENT CONNECTION

a) When installing a pump, whether internally or externally, always install an open-air vent, free

and correctly sized to prevent the formation of a vacuum and deformation of the tank when the

pump is running. After connecting the vent, make the connections and check them.

b) In order to prevent the formation of bad smells and, consequently, enable the treatment plant to

function efficiently, ALWAYS connect a pipe (PVC or PE) to the connection point provided for the

biogas vent on the tank cover. Run the pipe to the highest point of the building or along the

downpipes, but in any case higher than the level of the roof.

The pipe indicated on the drawing for venting is not included in the supply.

2.5 MANHOLE INSTALLATION

The installation of manholes or covers of weight exceeding 50kg

must always be solid with the concrete slab, suitably designed for the

load to support and exerting a uniformly distributed load over the

tank. The slab, therefore, must NOT be constructed directly on the

tank but must rest on undisturbed, load-bearing ground. AVOID

constructions in brickwork which would compromise maintenance

and/or eventual replacement of the tank.