19

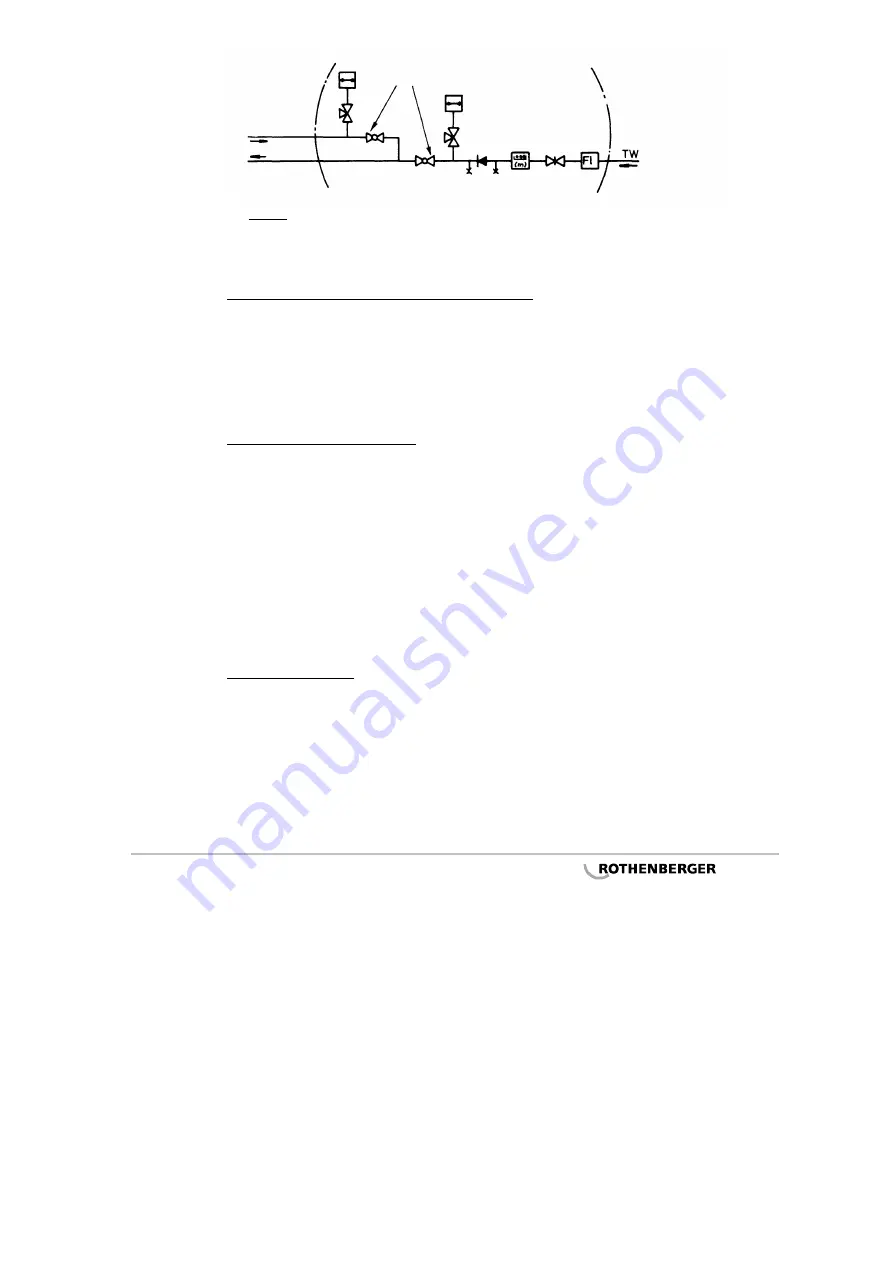

The design of the compressed air–water mixer and the respective fittings may follow fig. 18.

Fig. 18

compressed air – water mixer

To protect sensitive fittings and appliances (e.g. drinking water heater) against damage from

flushed-in solids, we recommend that such parts are installed only after the flushing and to first

fit sleeve sock.

11.3 Preparation of initial

operation and handing over

Whoever installs the equipment must prepare the handing over and acceptance reports.

Furthermore, the manufacturer must provide maintenance and operating manuals for the

installed protection and safety fittings and the appliances (also see DIN 1988, part 8.).

Sanitizing – flushing – pressure testing for piping in domestic technology is an ‘approved rule of

technology”.

3.2

Checklist for Flushing to DIN 1988, part 2, paragraph 11.2

Technical prerequisites for flushing:

-

Has it been connected to the public supply system? If not, may the flushing water be drawn

from a hydrant?

-

Has a DIN/DVGW approved micro-filter been fitted?

-

What is the supply pressure from the utility (also refer to items 3.3 and 3.4)

-

Has all the installed water piping been pressure tested?

-

For later checks, one or more control pieces should have been fitted.

-

Cold and hot water pipes must be flushed separately.

-

Fittings, which might reduce the initial pressure, may have to be dismantled.

-

Pipe length 100 m max., after which sleeves to be fitted (if possible provide for it during

installation).

Questions on plumbing:

-

The plumbing is in

galvanized steel pipe DIN 2440

Cu pipe

DIN 1786

PVCh pipe

DIN 8062

PEh pipe

DIN 8074

Mix of galvanized steel pipe / Cu pipe

Fittings for simultaneous fast

opening and closing

Compressed

air

Air-water

mixture

ENGLISH

Содержание ROPULS

Страница 84: ...82 OPTIONAL H8 1063 H8 1138 www rothenberger com 9 0100 ...

Страница 86: ...84 Notes ...

Страница 87: ...85 Notes ...