5

EN

2. Transportation and storage

2.1 Transportation for assembly

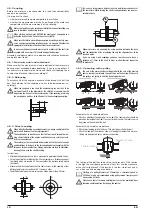

Incorrect handling can cause serious damage to the device.

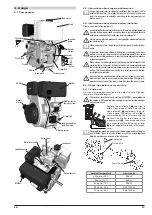

You can pick up the device using the motor base plate (using noo-

ses) and move it.

Pay attention that the lifting point is not located in the centre of the

device.

Persons have to keep a safety distance during lifting operation.

Make sure that the lifting gear and the supporting construction is sui-

ted to carry the weight of the device.

Please also consider following points:

• All used lifting means must be in good order.

• The loading capacity must be suited to the weight of the load.

• Wrong movements can cause personal injury or serious damage to the device.

• Make sure nobody is in the vicinity of the hanging motor.

• When picking up the device vertically it is important to position the lifting point

exactly into the focal point. Additionally, guide rope should be used.

• It is forbidden to pick up the device outside in unsafe weather conditions (i.e.

strong wind, storms).

• Always put down the engine carefully onto an even surface that suits the

weight of the device.

2.2. Storage as newdrive

• If the device is not used instantly, the engine has to be stored at a safe, clean,

dry and vibration free location (only if no fuel and/or oil were filled into the

device).

• Should there be a starter battery included in your order (which is not the de-

fault), please consider following points:

Make sure to disconnect the minus (-) pole first and the plus (+) pole

second. During assembly the plus (+) pole is connected first, the minus

(-) pole second.

When storing batteries without battery loader make sure the tempe-

rature of your storage room is at 20°c. Do not forget to charge the

battery every 3 months. The self-drain can significantly shorten your

batteries lifespan.

• The ball bearing does not have to be cared for when the device is in storage.

2.3. Prolonged downtime/Storage

2.3.1. From 30 days to 6 months

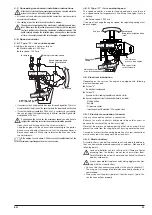

If a previously used device is to be stored for longer than 30 days

follow these instructions:

• Start the motor and let it get to operating temperature (about 5 minutes of

running the engine).

• Stop the motor and drain the lubricating oil using the drain plug.

• Fill motor protection oil into the device and let it run for 5 minutes.

• Drain the motor protection oil when the engine is still warm and replace it with

normal motor oil.

• Drain the fuel, clean the diesel tank if necessary, and maybe change the filter.

• Clean the device and conserve it with oil mist.

• Close up all suction intakes with masking tape (recoil starter, air filter)

• Remove the injection nozzle, add a few splashes of motor oil into the cylinder

and turn the motor with your hand to distribute the oil. Reinstall the injection

nozzle.

• Add splashes of oil into intake- und exhaust-manifold, Rocker-arm, valves,

valve-rod etc. and protect non painted parts with fat.

• Disconnect the battery and remove it from the device and, if available, connect

it to a battery loader.

Consider during disassembly the minus (-) pole is disconnected first

and the plus (+) pole second. During assembly the plus (+) pole is

connected first, the minus (-) pole second.

When storing batteries without battery loader make sure the tempe-

rature of your storage room is at 20°c. Do not forget to charge the

battery every 3 months. The self-drain can significantly shorten your

batteries lifespan.

• Wrap the engine in plastic foil.

• Only store at dry locations.

• Preparation for reactivation:

• Remove all cladding and protective foil.

• Put the engine in operation following the instructions for first start-up.

2.3.2. Longer than 6 months

Additionally to the instructions in 2.3.1.:

• lube-system, fuel-system, and all moving parts are to be protected with slus-

hing oil SAE 30 (ex. ESSO RUST, AGIP RUSTIA). Turn the motor to distribute the

oil and drain the excess.

• Every so often turn the motor by hand.

Preparations for reactivation:

• Remove the intake-manifold, pour motor oil close to the valves, turn the motor

shaft a few times and change the oil without starting up the engine.

• Check the valve-clearance and oil- and air filtration.

• Do the earlier service instructed by the motor operation hour maintenance

chart (i.e. after 120 operation hours the 200 hour service should be executed).