EN

10

4.6. Coupling

Before the motor can be connected to a load their compatibility

needs to be checked!

It is important to check

• whether motor and load are compatible in oscillation

• whether the measurements of shaft and flange of the motor are

compatible with the measurements of the coupling.

Motor and load have to be levelled carefully! An incorrect levelling can

lead to vibrations and bearing failure.

When starting up the motor BEFORE the montage of a coupling or a

pulley the key has to be fixed to the nut very tightly!

Make sure that while assembling a coupling or a pulley all safety mea-

sures concerning touching rotational parts are obeyed. Consider the

appropriate installation instructions from the manufacturer.

In no case whatsoever should pressure, hits or blows hit the shaft (for

example with a hammer). This could damage the bearings.

Assembly and disassembly has to be done with suitable attachment

and detachment tools!

4.6.1. Maximum axial and radial load

Make sure that the maximum axial and radial load of the motor main

bearing aren’t exceeded before operating. If you’re using pulleys it

is necessary to recalculate the life-span of both shaft bearings and

to adjust maintenance intervals accordingly.!

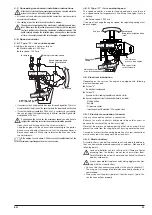

4.6.2. Balancing

The crankshaft of the engine is dynamically balanced with half the

key. Each element of the coupling also has to be balanced out ac-

cordingly.

When the coupling is too short the overhanging key part has to be

worked off until it is the diameter of the shaft

or covered up with

rings using the key nut in the according size. If the coupling is too long

the missing key part has to be filled out in the overhanging coupling.

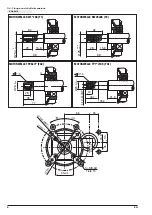

4.6.3. Direct coupling

When directly attaching a moving element (ex. pump, ventilator) to the

motor shaft, balance is extremely important!

The coupling has to be chosen so that the transferred torque, the run-

ning characteristics of the engine and the necessary safety characte-

ristics are considered.

The motor plus the load should be balanced out so that out-of-rounds

and deviations in balance of the two coupling halves comply with the

tolerance of the manufacturer. Sloppy balancing can lead to vibrations,

bearing failure or to the shaft breaking.

Instructions:

• Attach both coupling halves so that a movement is possible with both halves.

• Set up the parallelism of both shafts with a comparator or a thickness gauge at

four points which are located 90° from each other (the distance set up equals

the value A).

• Measure the distance between the two contact-areas of the coupling at four

different points which are also set 90° from each other.

• The difference between the two values may not be greater than 0.05mm.

A

A

A

A

A

A

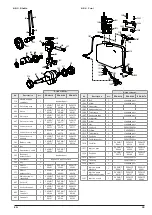

You can use two measure-devices to set up parallelism and coaxal at

the same time. While turning the shaft slowly deviations can be mea-

sured precisely.

Alignment errors are corrected by using washers between the base

and the foundation. After refastening the nuts the alignment has to be

checked again.

If you are using 2-part couplings you have to make sure to leave a

distance of 1-2mm to the shaft in order to allow thermal expansion

of both shafts.

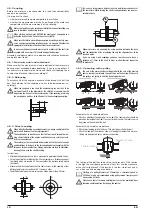

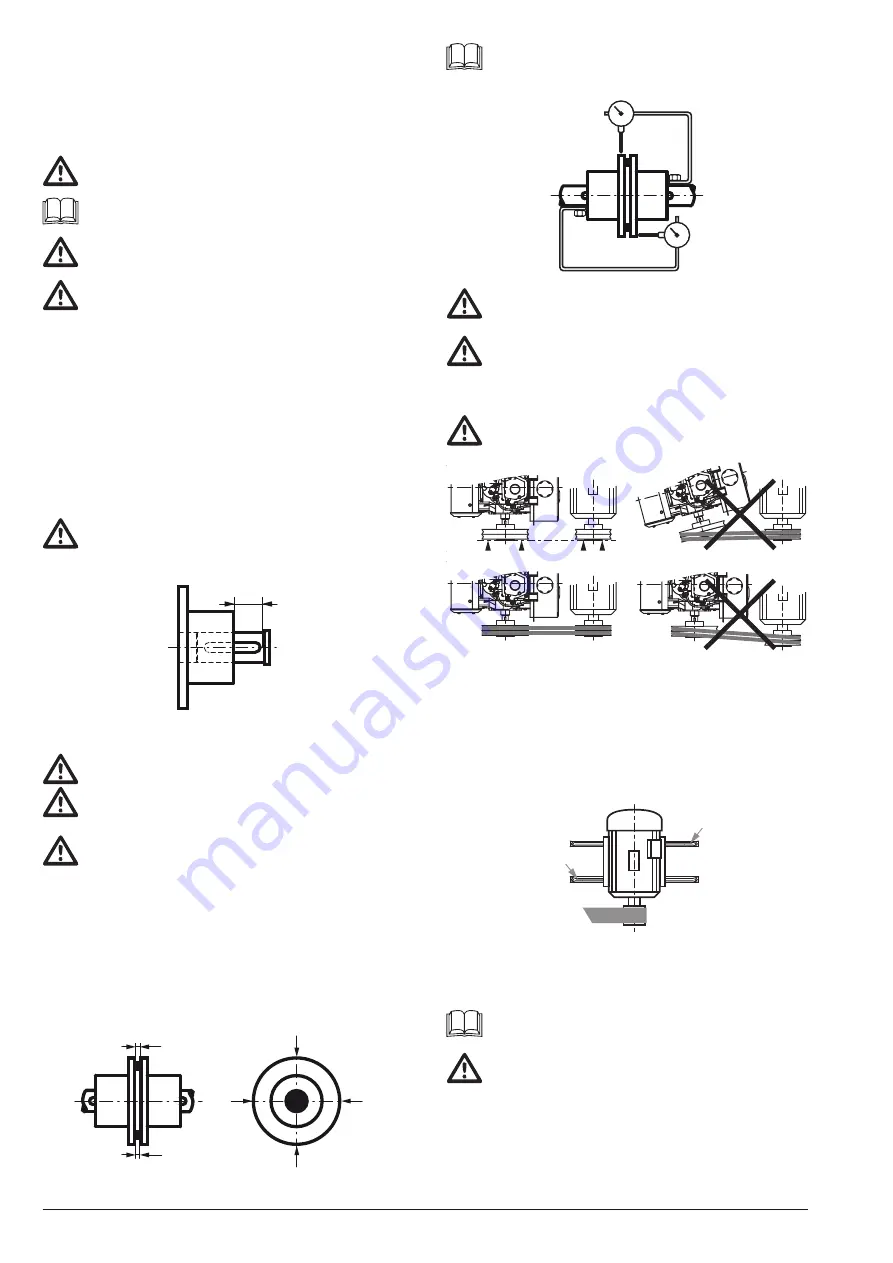

4.6.4. Operating with a pulley

The axis of the motor shaft must be parallel to the axis of the moving

device, in order to minimize the axial force on the bearing. Make sure

the pulleys are set up in one line (see diagram below).

Assembly with a fixed axle distance:

• Attach an additional tension roller to the belt. The tension roller should be

placed on the inside of the V-belt. In case a flat belt is used - the roller can also

be placed on the outside of the belt.

Assembly with variable axle distance:

• Attach two clamping rails to the base. They must be parallel to the belt.

• Attach the load (not the motor) as shown in the diagram below. This way eve-

rything can be balanced out as precisely as possible.

Tension screw

Tension screw

The tension of the belt has to be set up very precisely. If the tension

is too high the shaft bearing wears out very fast and the crankcase

or the shaft might break. If the tension is too low, vibration can oc-

cur, which can also damage the device.

Starting at a pulley diameter of 315mm and a rotational speed of

3.000min

-1

we do not recommend using pulleys made from gray cast

iron or using flat belts.

Please note that all moving (rotating) parts must be protected from

touching anything before starting up the device!