HDBH Series Operating Instructions

www.rosscontrols.com

5

7.1.2. Filtration:

Fluid cleanliness is a necessity in any hydraulic system. Fluid

filters need to be installed and maintained in the system to provide the required level of

cleanliness. Filters can be placed in the inlets.

7.1.3. Accessory Ratings:

All accessories used in combination with the

selected or intended HDBH valve system must be used in accordance with the HDBH

specifications.

7.2. Electrical Connections

Install the electrical connectors (EN 175301-803 Form A type, pre-wired or non-

prewired) for both the valve solenoids.

Install the inductive position switch connector (M12, 5-pin, A-coded) on each valve and

follow the electrical wiring schematics of the switch on page 2.

8. Commissioning and Operation

CAUTIONS

Damage to health due to loud noise!

Levels above 70 dB(A) may lead to damage to health!

f

Always wear ear protectors when working on the product.

Before commissioning, the installation must be carefully inspected by a qualified,

trained professional.

Make sure that the technical specifications match the operating criteria of the machine

and/or the hydraulic system.

8.1. HDBH Test Procedure for Valve Operation

NOTE 1: This valve test procedure only checks for proper function of the HDBH

system. Please refer to the HDBH Integration Guide for the External Monitoring

Validation Procedure.

NOTE 2: The valve test procedure requires fault simulation. It will be necessary

to induce faults electrically by disabling a different solenoid or switch at different

times. This will be most easily done by disconnecting solenoid or switch cables

at the valve.

NOTE 3: The HDBH is designed to work in association with a directional control

valve and a cylinder (or other actuator). The following test procedure only

checks the function of the HDBH system, and it may be necessary to modify this

procedure to accommodate the various operating modes of the directional valve

being used with the HDBH.

NOTE 4: The PNP position switches are supplied with both NC and NO contacts.

NOTE 5: - indicates no change from previous step.

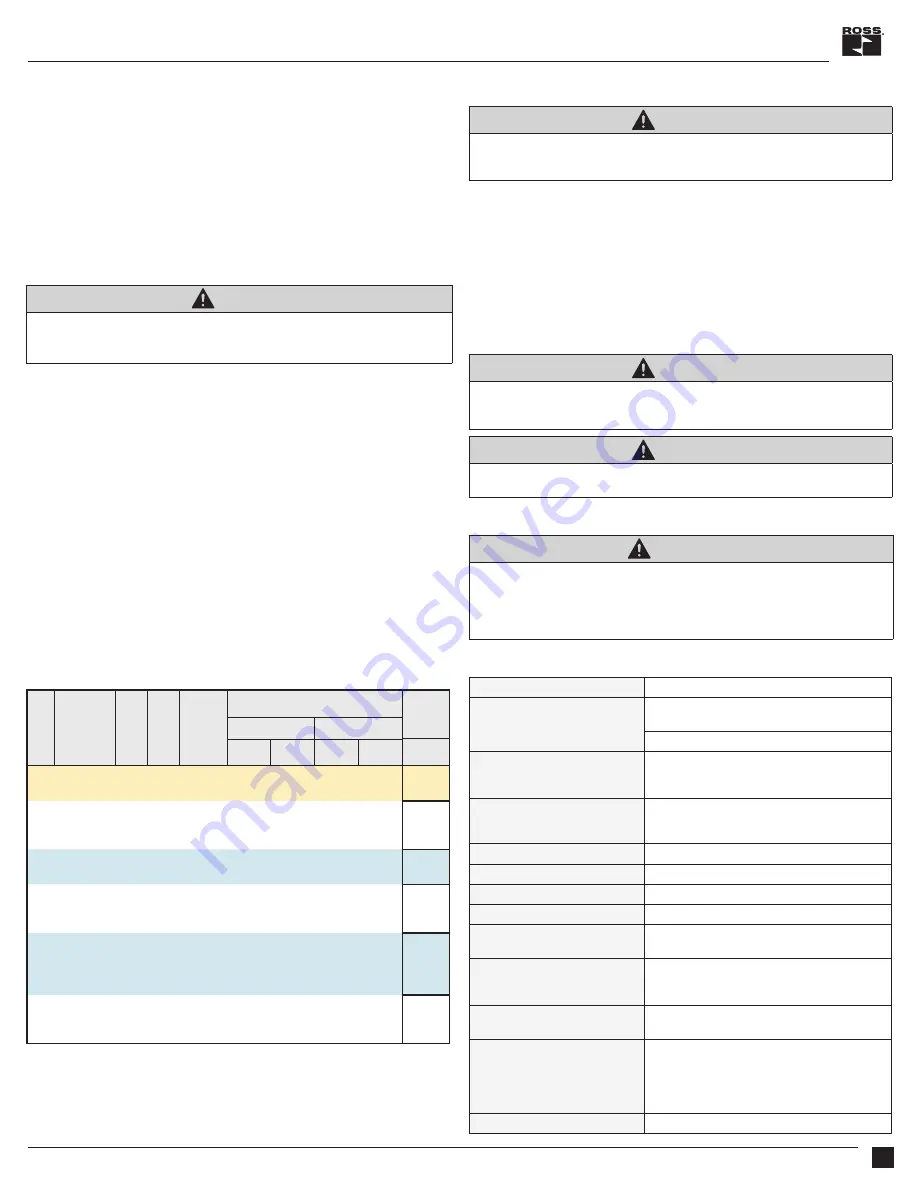

Step

Action

Sol 1A Sol 1B

Flow

YES/NO?

Switch Conditions

Pass/Fail

Switch 1A

Switch 1B

(NC)

(NO)

(NC)

(NO)

(P/F)

1

Energize

solenoid 1A ON

OFF

NO

OPEN CLOSED CLOSED OPEN

2

De-energize

both

solenoids

OFF

OFF

NO

CLOSED OPEN

-

-

3

Energize

solenoid 1B OFF

ON

NO

-

-

OPEN CLOSED

4

De-energize

both

solenoids

OFF

OFF

NO

-

-

CLOSED OPEN

5

Energize

both

solenoids

1A & 1B

ON

ON

YES

OPEN CLOSED OPEN CLOSED

6

De-energize

both

solenoids

OFF

OFF

NO

CLOSED OPEN CLOSED OPEN

8.1. Limitations Due to System Leakage

Even though the HDBH is designed to redundantly block flow, it is important to

periodically test for leakage within the HDBH and the system it controls, as any leak

within the HDBH itself, interconnecting hoses, connectors, cylinders or other actuators,

or even other valves in the circuit may cause unexpected movement. In order to test

for leakage within the HDBH itself, it is necessary to check for actuator (cylinder)

movement when the HDBH is in each of the following conditions:

WARNING

Performing this test could cause injury or damage to equipment due to unexpected or

uncontrolled movement. Take all necessary precautions to ensure worker safety prior to

initiating this test.

A) fully de-energized (both solenoids 1A & 1B de-energized)

B) solenoid 1A energized with solenoid 1B de-energized

C) solenoid 1A de-energized with solenoid 1B energized.

Depending on the application, it may be necessary to preposition actuators and/or

other valves such that energizing the HDBH would allow motion to occur. This sets up

the circuit so that the HDBH valve is the sole motion-controlling device during testing.

For example, if a cylinder is fully retracted, a leak that normally allows retract motion to

occur could be masked because the cylinder is already fully retracted.

This test helps to troubleshoot leaks within the HDBH system. Other leaks within the

associated system can affect the outcome of this test.

WARNING

If any leakage is discovered within the system, measures should be taken to eliminate the

leak(s) as failing to do so could limit the ability of the safety system to safely stop motion

when required.

WARNING

Continued operation of the system without periodic leakage inspections can lead to unexpected

movement.

9. Disconnecting and Removal

CAUTIONS

Risk of injury due to installation while pressurized or with live parts!

f

Disconnecting a hydraulic component while the system is pressurized or while electrical power

is supplied can result in injury or death due to sudden pressure release, unexpected movement,

or electric shock.

f

Isolate and lock out the electrical and hydraulic systems before disconnecting the unit

.

10. Technical Specifications

Construction Design

Spool type

Actuation

One solenoid per valve element

Solenoids must be operated synchronously

Direct solenoid operated, spring return

Mounting

Type:

Sandwich-style mounted (interposed) between

base/manifold and directional valve

Footprint:

ISO 4401-03-02-0-05 (NG 6 or D03)

Solenoids

Version as per VDE 0580. Rated for continuous duty.

Electrical connection according to EN 175301-803 Form A

Enclosure rating according to DIN 400 50 IP 65

Standard Voltages

24 volts DC

Power Consumption

(each solenoid)

30 watts

Inductive Position Switch

(2 per system)

PNP (M12, 5-pin, A-coded)

Maximum Current

(each switch)

400mA maximum

Temperature Range

(recommended)

Ambient: -

22° to 160°F (-30° to 70°C)

Media:

-4° to 140°F (-20° to 60°C)

Flow Media

Hydraulic Fluids:

Mineral Oil HLP, HL-DIN 51524

Vegetable Oil HETG - VDMA 24568

Pressure

Ports P, A, B :

5000 psi (344 bar)

Port T :

3000 psi (210 bar)

Construction Material

Valve Body:

Cast Steel

Spool:

Steel

Seals:

Buna-N

End-brackets:

Unfilled Nylon 12

Side-brackets (label):

304 Stainless Steel

Functional Safety Data

MTTFd: 150 years