Notice originale : Français NT0002 V –p – 03/2014

31

Spreading

Put the Power Take- Off moving without accelerating and bring it to normal speed of 1000

rot. / min.

Every spreaders ROLLAND are studied to operate in this way except in particular case (540

rot. /mn). In every cases, the scheme to be used is specified in a stitcher in the pipe holder

nose in the front of vehicle.

If the quality of spreading is not satisfactory, many things might be the cause: look for

the cause in the following points:

Adapt the settings in relation to manure.

The loading (irregular, not homogeneous).

The power of your tractor (too weak).

The rotation speed of the Power Take-Off (too slow – control the scheme) Check the

flow.

In case of tamping of manifold or table, invert the advance of moving background to get free

the manifold, consign the machine (see § 1-1 on page 3) and manually remove material

blocking the machine from the rear (see page 32). To do this handling, the use of Individual

Protection Equipment is mandatory. (gloves, glasses, helmet,…)

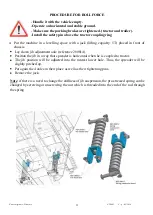

Regulator can also be used in manual mode in case of breakdown. To turn into manual mode,

you should turn the thumb wheel clockwise. Since the tightening of thumb wheel, the

regulator goes to manual mode, then it is just necessary to adjust the settings according to

needs.

To return to electric mode, you should only loosen as much as possible the thumb wheel.

If there is a failure of distributor or control box, you can connect the flexible pipes that come

out of distributor directly to the tractor.

1

EACH INTERVENTION IN THE REGULATOR

(REGULATION OF MANUAL MAINTENANCE FOR

EXAMPLE) SHOULD BE DONE WITH MACHINE

ABSOLUTELY

STOPPED.

(TRACTOR

ENGINE

TURNED, KEY OUT OF IGNITION). FOR RESTART,

CHECK §1-2 page 3).

SAME INSTRUCTIONS TO BE APPLIED IN CASE OF

MANUAL REGULATOR (SEE PAGE 12). IN

ADDICTION THE REAR GLASS OF THE TRACTOR

CABINET SHOULD BE IN CLOSED POSITION

DURING

THE

MACHINE

OPERATION.(

SEE

GENERAL SAFETY INSTRUCTIONS ON PAGE 3)