7

5 Basic Operation

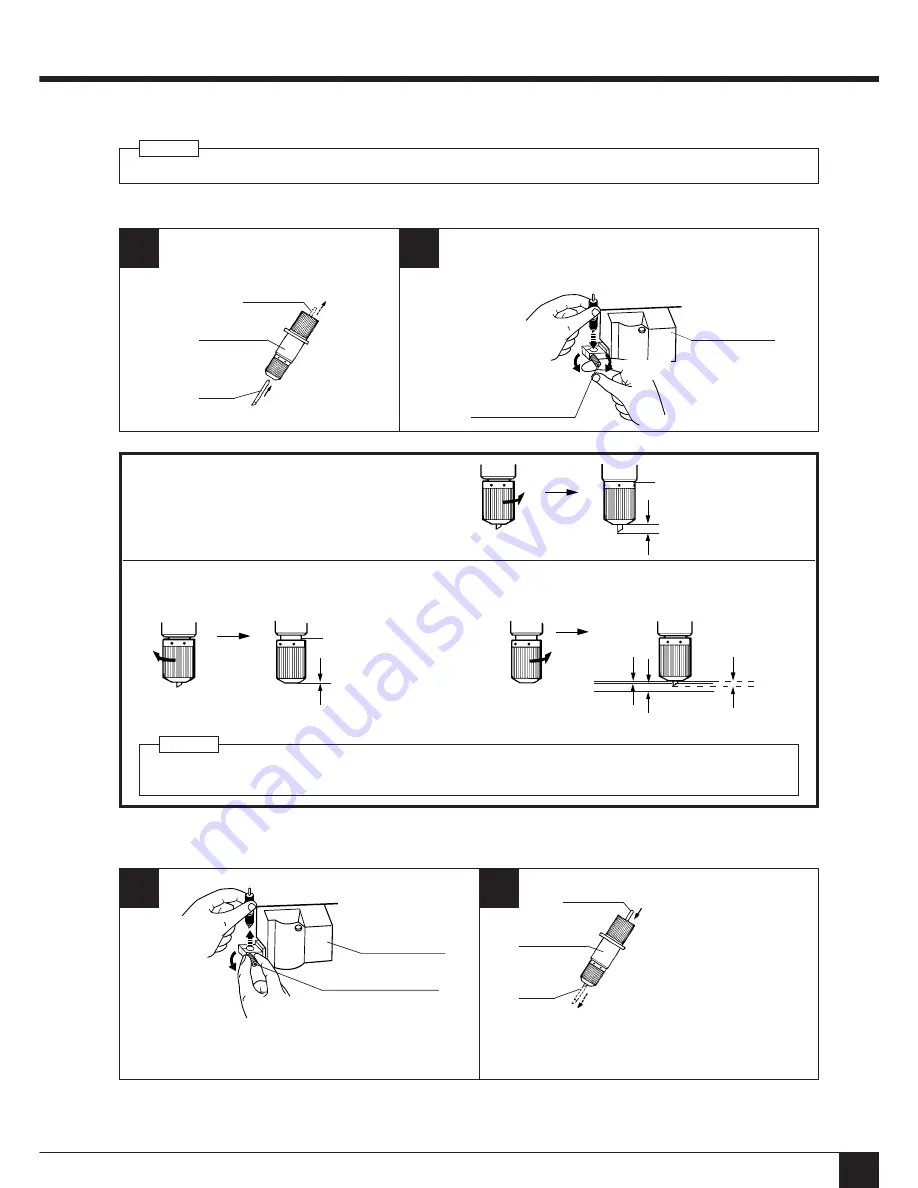

Tool-securing screw

1

Press the push-pin and

remove the blade from

the blade holder.

2

If a blade was used, wipe the blade with a soft cloth to

remove any material that may cling to it.

Leave the tool-securing screw loose. Tightening the screw makes

it more difficult to install the blade holder.

1) Loosen

2) Remove the blade holder from

the cutting carriage.

Cutting carriage

Blade

Push-pin

Blade holder

Removal

5-3 Installing/Removing a Blade

Do not touch the tip of the blade. This could impair the cutting performance of the blade.

Installation

NOTICE

1

Insert blade into the blade holder until it

snaps into place with an audible click.

Blade

Push-pin

Blade holder

2

2) Support the tool-securing screw from below and install the blade

holder.

* Insert the blade holder until the collar is flush with the carriage.

Tool-securing screw

1) Loosen

3) Tighten

Cutting carriage

Adjusting the

Cutter Blade

Blade adjustment may be necessary when:

- cutting material whose carrier paper is thinner than the material itself

- cutting material with no carrier paper

When cutting is performed after printing, the cap tip of the blade holder may scratch the printed surface. If this is the case,

lengthen the cutter blade extension.

When stock vinyl film is to

be cut, tighten the cap all

the way (2.5 mm (about

0.1") of blade extension).

Tighten the cap until

gap is eliminated

Amount of cutter blade

extension: 2.5 mm (about

0.1") (maximum length)

1)

Gap

Amount of cutter blade

extension: 0 mm

Turn the cap as shown by the

arrow to align the tip of the

blade with the tip of the cap

2)

Amount of cutter

blade extension

Thickness of the carrier paper

Thickness of the

sheet portion

Turn the cap as

shown by the arrow

NOTICE

Turn the cap as

shown by the arrow

Содержание ColorCAMM PNC-5000

Страница 1: ...USER S MANUAL...

Страница 19: ...B3010896BE R3 1...