14

9 Care and Maintenance / 10 What to Do If...

Cleaning the main unit

For routine cleaning, use a soft piece of cloth.

Cleaning the printing head

9 Care and Maintenance

• Be sure to turn off the power to the PNC-5000 before cleaning.

• Never attempt to oil or lubricate the mechanism.

NOTICE

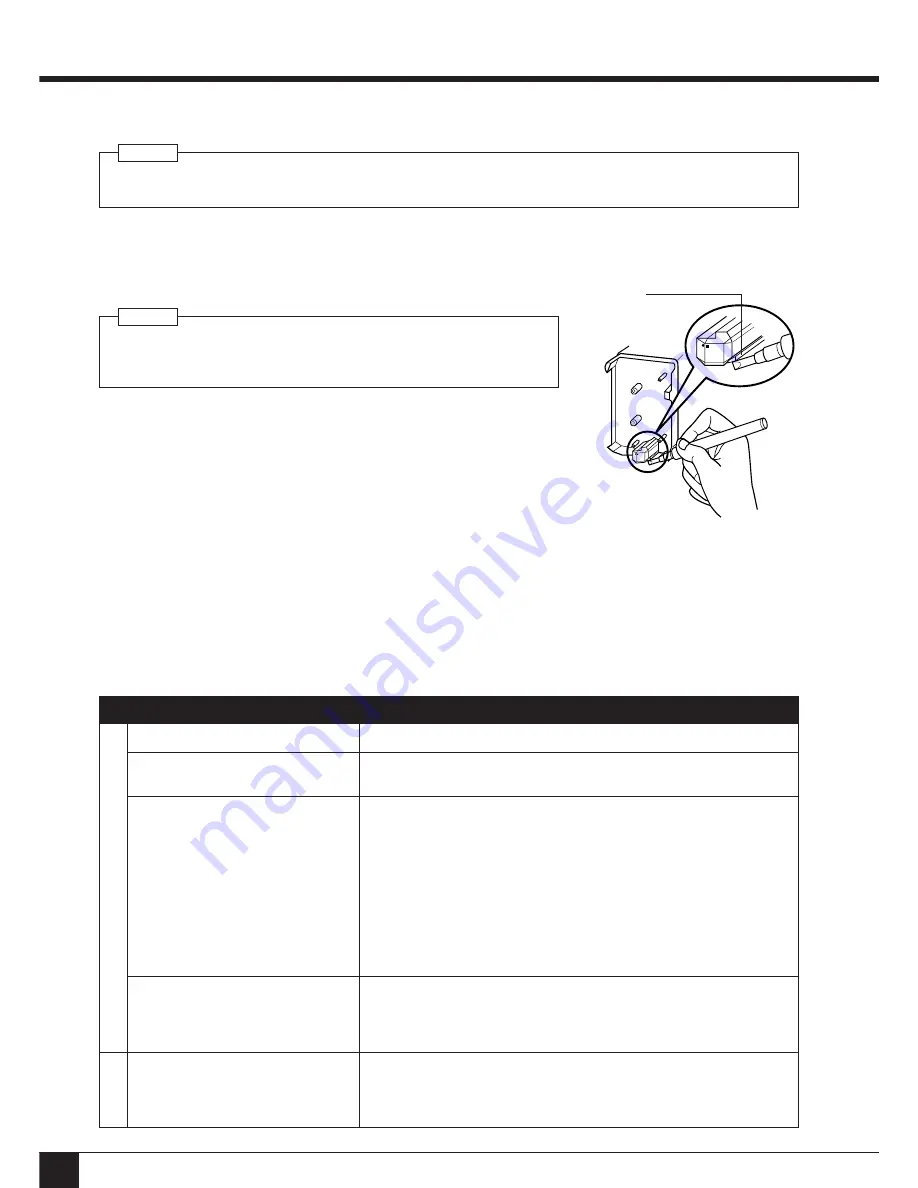

Open the cover and remove the ribbon cartridge.

To remove any soiling on the printing head, use a head cleaner included with the PNC-5000.

After cleaning, refer to “5-10 Performing a Self-test” to check operation and make

sure that the PNC-5000 is working correctly.

* If high-quality printing is desired, the printing head should always be kept

clean to prevent buildup of grime.

Cleaning the platen

If the platen becomes soiled, wipe it clean with a dry, soft cloth.

Do not wipe with a head cleaner or alcohol.

Use care when cleaning to avoid damaging the surface of the platen. Damage to the platen may impair the accuracy of printing.

Drops of cleaning fluid may spray out when the cap is opened. Hold away from the

platen when opening the cap. The platen may be discolored by any cleaning fluid

that comes in contact with it. (The cleaning fluid is non-toxic.)

NOTICE

10 What to Do If...

If you want to completely stop the operation of the PNC-5000, turn off the power switch.

Is the PNC-5000 power on?

Turn on the power. (See “5-2 Powering On” .)

Is the unit in SETUP status (the

SETUP LED is lit)?

If the SETUP LED is not illuminated, make sure the material is loaded correctly

and press the SETUP key to illuminate the SETUP LED.

Is the PAUSE LED illuminated?

If the PAUSE key has been pressed and the PAUSE LED is lighted, the unit has

been paused (see “5-7 Pausing Operations” ).

To resume printing or cutting, press the PAUSE key again. The PAUSE LED is

extinguished, and printing or cutting resumes.

To terminate printing or cutting, first stop the transmission of printing or cutting

instructions from the computer to the PNC-5000. Then press the SETUP key.

This deletes the printing or cutting instructions that have already been sent from

the computer to the PNC-5000, and printing or cutting is stopped.

If operation is still not correct when the next batch of data is sent after printing or

cutting, or cutting has been stopped, switch the power off and then on again.

If connected via the serial port, do the

communication parameters for the

PNC-5000 match those of the

computer?

Set the DIP switches correctly (see “5-1 DIP Switch Settings” .)

PNC-5000

Is the computer set up correctly?

Check the following items:

• DIP switches

• Memory switches

• Interface board

• Communication parameters

• Other settings

Read the computer user’s manual and set it up correctly.

Computer

If the PNC-5000 doesn't run...

Printing head

Содержание ColorCAMM PNC-5000

Страница 1: ...USER S MANUAL...

Страница 19: ...B3010896BE R3 1...