11

5-9 Cutting Test to Check Cutter Force

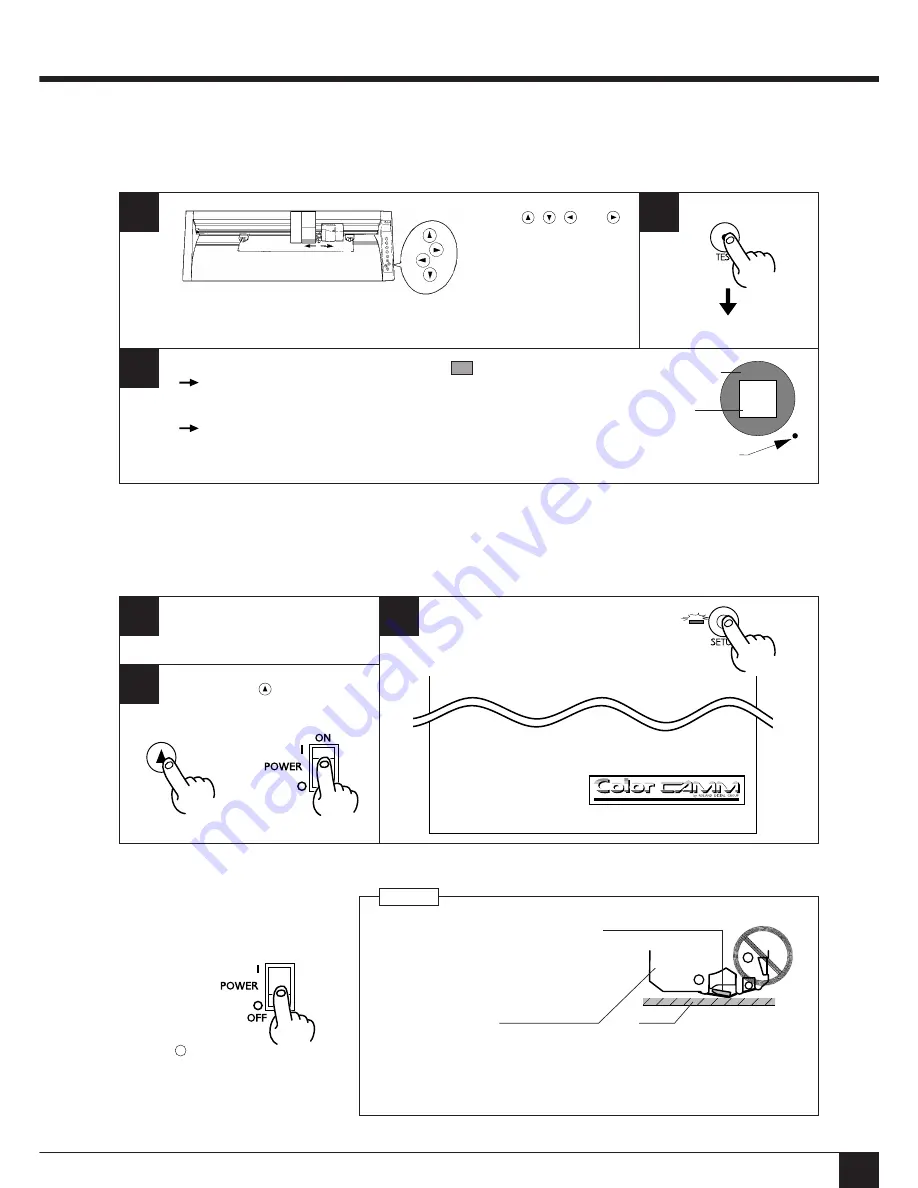

Before cutting, you may wish to perform a “cutting test” to learn whether the unit cut satisfactorily. If cutting is to be continued on the

same material, there is no need to perform a cutting test.

Move the cutter force control slider all the way to the left (minimum cutter force).

1

2

* Note that an area of approximately 2 square centimeters (a little less than a square inch) is

required to make a test cut.

Use the

,

,

, and

keys to move the tool

carriage to the position on

the material where the

cutting test is to be executed.

Cutting test starts.

1) First peel off the round section (shaded as shown

).

When it can be peeled by itself, without disturbing the square, the cutter force is set

appropriately.

2) Next, peel off the square, and look at the backing behind it.

The optimum blade pressure is correct if you can clearly make out the lines left by the blade.

Adjust the cutter force control slider until results as shown above are obtained.

(Gradually increase the cutter force until you reach the optimum level.)

3

Then peel

this off

Peel off first

Press the TEST key.

5-11 Powering

Off

• Do not switch off the power while the

printing head is lowered. Doing so

may damage the head and impair

printing performance.

5-10 Performing a Self-test

The PNC-5000 is equipped with a “self-test” function to allow you to check whether or not it is capable of operating normally. If the

PNC-5000 is not performing correctly, follow the steps below to perform a self-test.

A computer is not required in order to carry out the self-test.

1

Install a blade and ribbon cartridge

in the PNC-5000.

Performing a cutting test.

3

Load the material, and press the SETUP key.

Operations is normal if the figure shown at below.

Press the side of

the switch marked

with “

”.

• When the unit is not in use, keep the pinch rollers raised. The pinch rollers may be

deformed if left engaged.

• If you do not intend to use the unit for an extended period of time, disconnect the

unit from the power outlet.

Platen

Ribbon cartridge

Printing head is lowered

NOTICE

2

Hold down the

key on the panel

while you turn the power on.

+

5 Basic Operation

Origin (when

using roll material)

Содержание ColorCAMM PNC-5000

Страница 1: ...USER S MANUAL...

Страница 19: ...B3010896BE R3 1...