MP-Series Food Grade Servo Motor Installation Instructions

13

Publication MP-IN004D-EN-P — April 2009

Attach Motor Cables

Follow these steps to attach the feedback, and power/brake cables after the motor

is mounted.

1.

Form a drip loop in the cable before attaching it.

A drip loop creates a low spot in the cable. Gravity causes any liquid to flow

to the low spot and away from the connectors, thereby reducing the

potential for any liquid to enter the connector.

2.

If you use a cable with a quick-lock plug, remove the O-ring on the

feedback or power/brake connector.

Only threaded cable plugs require the O-ring on the connector. The O-ring

dampens the effects of vibration at the cable-to-motor connection and

creates a more secure connection for a threaded plug. O-rings interior to the

cable plug provide complete environmental sealing for a cable with a

quick-lock plug or a cable with a threaded plug.

ATTENTION

Make sure that cables are installed and restrained to prevent uneven tension or flexing at

the motor-to-cable connections.

Excessive and uneven lateral force at the motor connectors can result in the connector’s

environmental seal opening and closing as the cable flexes.

Failure to observe safety precautions could result in damage to the motor and its

components.

IMPORTANT

Cables requiring O-rings include power cable 2090-XXNPMF-

xx

S

xx

or

2090-CP

x

M4DF-

xx

AF

xx

, and feedback cable 2090-XXNFMF-S

xx

or

2090-CFBM4DF-CDAF

xx

.

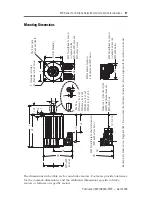

O-rings

Align Flat

Surfaces

Feedback Plug

Power/Brake Plug