MAN F2000

Evolution

Baustufe 12

35

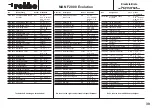

Stade 12, la benne

N° désignation

cotes (mm)

nbre

12.1

porte-palier

2

12.2

vis autotaraudeuses

Ø 2,2 x 6,5

4

12.3

châssis

1

12.4

cuve de la benne

1

12.5

longerons

2

12.6

traverses

2

12.7

porte-palier

2

12.8

vis

M 2 x 8

4

12.9

écrou

M 2

4

12.10

plaque de renfort, longue

2

12.11

montant

2

12.12

plaque de tête

1

12.13

plaque de renfort avant courte

1

12.14

plaque arrière

1

12.15

plaque de renfort arrière courte

1

12.16

charnière

2

12.17

vis

M 2 x 8

2

12.18

écrou

M 2

2

12.19

vis

M 2,5 x 12

2

12.20

écrou

M 2,5

2

12.21

écrou autobloquant

M 3

2

12.22

tige filetée

M 3 x 80

1

12.23

adhésif double face

1 n.c.

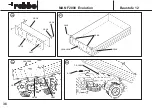

Indications concernant l'assemblage de la benne

Détacher tous les éléments fraisés des plaques-supports et

les ébarber.

Coller avec de la colle cyanoacrylate.

Lors du collage des éléments, veiller à ce que leurs arêtes

soient parfaitement à fleur et à angle droit. En présence

d'alésages veiller à ce qu'ils coïncident parfaitement.

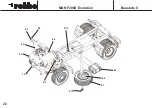

12a Fixer les porte-palier 12.1 avec les vis autotaraudeuses

12.2 sur la châssis 1.1.

12b Coller le châssis 12.3 sur la cive de fond de benne 12.4.

Veiller à ce que l'arête arrière, les arêtes latérales et les

alésages coïncident parfaitement. Pour l'alignement

engager des vis ou des goupilles métalliques dans les

alésages. Le châssis présente une saillie à l'avant.

-

Ajuster les longerons 12.5 et les traverses 12.6 et les

coller.

12c Monter les porte-palier 12.7 sur la cuve de la benne

avec les vis 12.8 et les écrous 12.9.

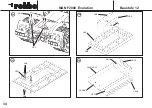

12d Coller les plaques de renfort 12.10 sur les montants

latéraux 12.11. Ce faisant, veiller à réaliser un montant

latéral gauche et un montant latéral droit.

Stage 12, the tipper body

Part No.

Description

Size (mm)

No. off

12.1

Bracket

2

12.2

Self-tapping screw

2.2 Ø x 6.5

4

12.3

Frame

1

12.4

Base plate

2

12.5

Longitudinal member

2

12.6

Cross-piece

2

12.7

Bracket

2

12.8

Screw

M2 x 8

4

12.9

Nut

M2

4

12.10

Long reinforcing plate

2

12.11

Side panel

2

12.12

Front panel

1

12.13

Short front reinforcing plate

2

12.14

Rear panel

1

12.15

Short rear reinforcing plate

1

12.16

Hinge

2

12.17

Screw

M2 x 8

2

12.18

Nut

M2

2

12.19

Screw

M2.5 x 12

2

12.20

Nut

M2.5

2

12.21

Self-locking nut

M3

2

12.22

Threaded rod

M3 x 80

1

12.23

Double-sided foam tape

1 N.I.

Constructing the tipper body

Separate all the machined parts from the milled panels and

remove all rough edges.

Use cyano-acrylate glue (“cyano”) for all joints.

When joining the parts check constantly that edges are

flush and the parts are at right-angles to each other. Holes

must line up accurately.

12a Fix the brackets 12.1 to the chassis 1.1 using the self-

tapping screws 12.2.

12b Glue the frame 12.3 to the base plate 12.4, taking care

to line up the rear edge, side edges and holes correct-

ly. Fit screws or pieces of rod through the holes to

ensure proper alignment. The frame projects at the

front.

-

Trim the longitudinal members 12.5 and cross-pieces

12.6 to fit and glue them in place.

12c Fix the brackets 12.7 to the base plate using the scr-

ews 12.8 and nuts 12.9.

12d Glue the reinforcing plates 12.10 to the side panels

12.11. Note that these parts are handed; take care to

produce one left and one right assembly.

Baustufe 12, die Mulde

Pos. Nr.

Bezeichnung

Maße (mm)

Anzahl

12.1

Lagerbock

2

12.2

Blechschraube

Ø 2,2 x 6,5

4

12.3

Rahmen

1

12.4

Bodenplatte

1

12.5

Längstraverse

2

12.6

Quertraverse

2

12.7

Lagerbock

2

12.8

Schraube

M 2 x 8

4

12.9

Mutter

M 2

4

12.10

Verstärkungsplatte, lang

2

12.11

Seitenwand

2

12.12

Kopfplatte

1

12.13

Verstärkungsplatte vorn, kurz

1

12.14

Heckplatte

1

12.15

Verstärkungsplatte hinten, kurz

1

12.16

Scharnier

2

12.17

Schraube

M 2 x 8

2

12.18

Mutter

M 2

2

12.19

Schraube

M 2,5 x 12

2

12.20

Mutter

M 2,5

2

12.21

Stoppmutter

M 3

2

12.22

Gewindestange

M 3 x 80

1

12.23

Doppelklebeband

1 n.e.

Hinweise zum Bau der Mulde

Alle Frästeile aus den Fräsplatten heraustrennen und ent-

graten.

Es wird mit Sekundenkleber geklebt.

Beim Verkleben der Teile darauf achten, daß Kanten bündig

und winklig miteinander abschließen. Bei Bohrungen auf

Deckungsgleichheit achten.

12a Die Lagerböcke 12.1 mit Blechschrauben 12.2 auf

dem Chassis 1.1 befestigen.

12b Den Rahmen 12.3 auf die Bodenplatte 12.4 kleben.

Darauf achten, daß Hinterkante, Seitenkanten und

Bohrungen deckungsgleich sind. Zum Ausrichten

Schrauben oder Drahtstifte durch die Bohrungen

stecken. Der Rahmen steht vorn über.

-

Längstraversen 12.5 und Quertraversen 12.6 einpas-

sen und einkleben.

12c Die Lagerböcke 12.7 mit Schrauben 12.8 und Muttern

12.9 am Muldenboden montieren.

12d Die Verstärkungsplatten 12.10 auf die Seitenwände

12.11 kleben. Dabei beachten: Es müssen eine rechte

und eine linke Seitenwand hergestellt werden.

Содержание MAN F2000 Evolution

Страница 10: ...MAN F2000 Evolution Baustufe 3 10 3 1 3 2 3 6 3 5 3 1 3 4 3 1 3 7 3 3 3 2 3 1 3 3...

Страница 20: ...MAN F2000 Evolution Baustufe 7 20 5 6 2 19 7 1 7 1 7 2 2 19 5 10 5 10...

Страница 22: ...MAN F2000 Evolution Baustufe 8 22 8 1 8 2 8 4 8 7 8 8 8 9 8 10 8 3 8 5 8 6 8 10 1 1...

Страница 30: ...MAN F2000 Evolution Baustufe 11 30 7 1 10 2 11 4 11c 11a 11b 11d 7 1 11 1 10 2 11 1 11 2 11 3 11 5...

Страница 42: ...42...