7 Maintaining the machine

20

We reserve the right to make technical modifications.

Rittal electrical crimping machine R8 E

EN

Fig. 15:

Oiling the crimping drum

7.4.3

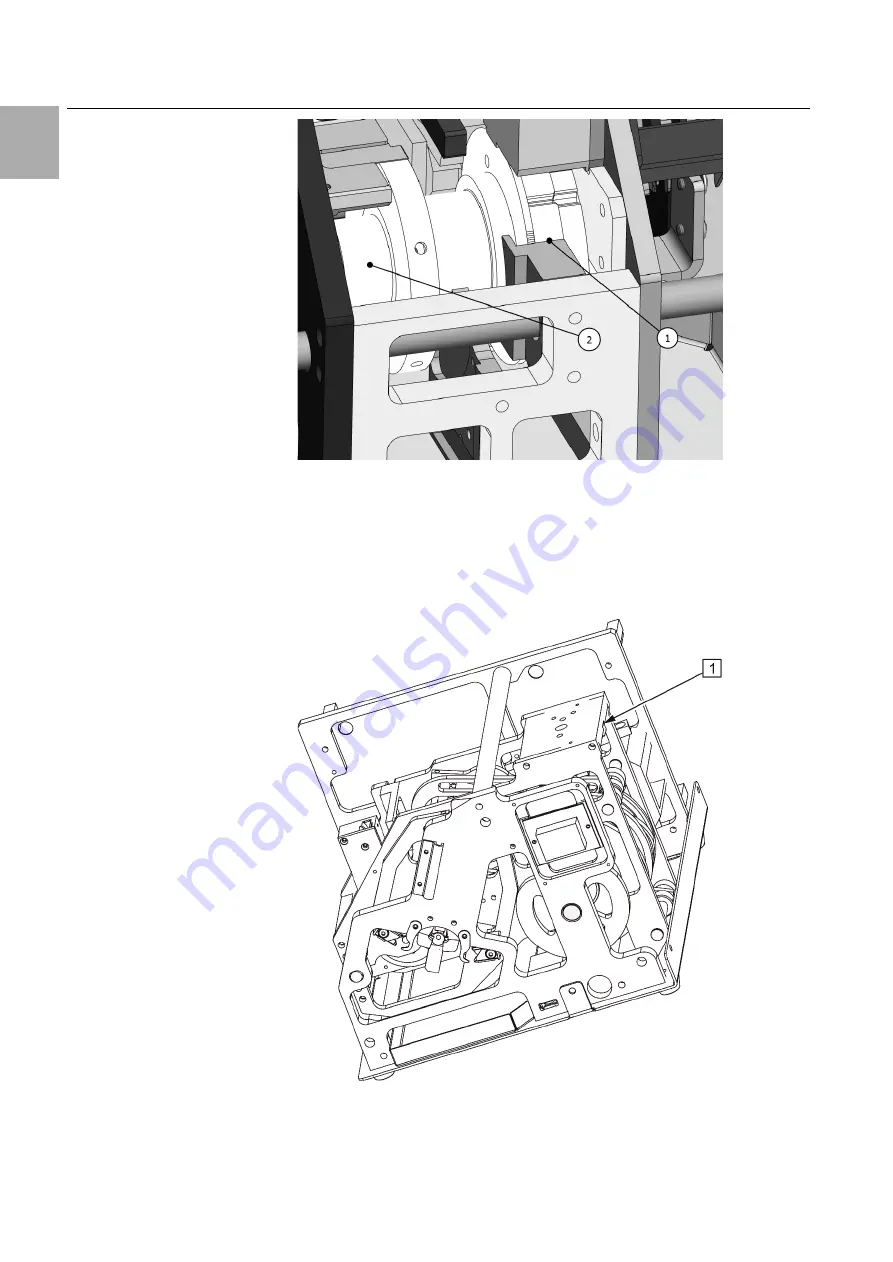

6-monthly maintenance

◼

Dismantle the housing.

◼

Oil the gap between the setting wheel and the insulation stripping stage.

◼

To do this, place the machine at 45°.

◼

Allow lubricating oil to flow into the gap (see fig. 16, item 1) between the setting

wheel and the cover.

Fig. 16:

Oiling insulation stripping stage setting