BARRIER

®

GLIDER Single Slide Model 7100

14

PUB. NO. 7100SSG FEBRUARY 2008

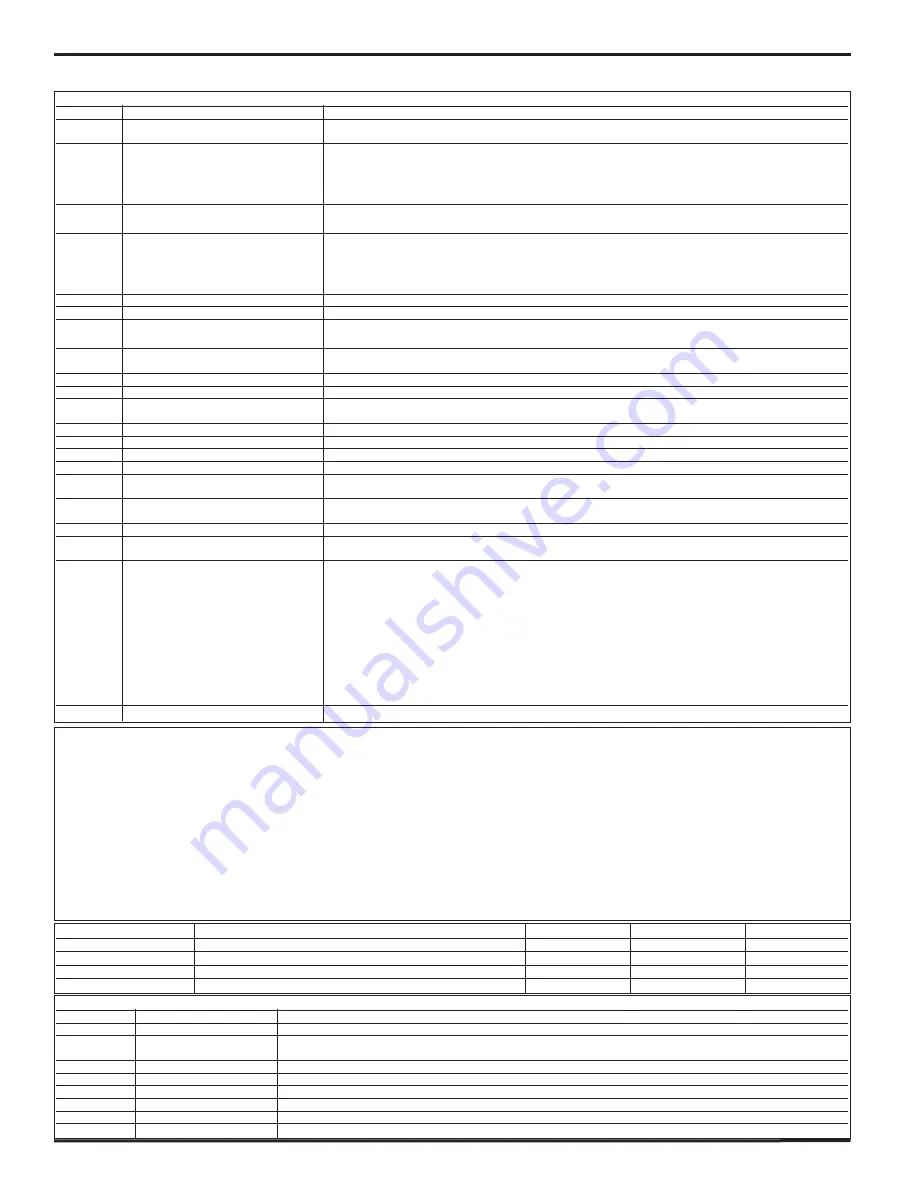

INVERTER ERROR CODES / PROGRAMMING

Barrier Glider - Inverter Error Codes

Trip Code Condition

Possible Cause

tr UU

DC bus under voltage

Low AC supply voltage, check power source.

Low DC voltage when supplied by an external DC power supply.

tr OV

DC bus over voltage

The DC bus (Pr. 84) has exceeded 800V-460V or 400V-230VAC, check the following:

If DC bus climbs while door is not running, disconnect CE filter with power off.

If fault is intermittent when door is not running try to set Automatic reset of faults.

(PR. 73 = 10.34, PR. 74=10.36, PR. 63 = 3, PR 64 = on) Deceleration rate set too fast

for the inertia of the machine. Mechanical load driving the motor.

tr It. AC

I2C on drive output

Motor wiring, check for loose connections or shorts.

Make sure door cannot move if brake is engaged.

tr OI.AC

Drive output instantaneous

Door is binding or jammed. Motor wiring, check for loose connections or shorts.

over current

Make sure door cannot move if brake is engaged. Disconnect CE filter with power off.

Insufficient ramp times. Phase to phase or phase to ground short circuit on the drives

output. Drive requires autotuning to the motor. Motor or motor connections changed,

re-auto tune drive to motor . MUST wait 10 seconds to reset after trip occurs

O.SPd

Over speed

Excessive motor speed (typically caused by mechanical load driving the motor)

tunE

Auto tune stopped before complete Run command removed before autotune complete

It.AC

I

2

-t on drive output current

Excessive mechanical load. Drive requires re-autotuning to motor.

High impedance phase to phase or phase to ground short circuit at drive output.

O.ht1

IGBT over heat based on

Overheat software thermal model

drives thermal model

O.ht2

Over heat based on drives heatsink Heatsink temperature exceeds allowable maximum

th

Motor thermistor trip

Excessive motor temperature

O.Ld1

User +24V or digital output overload Excessive load or short circuit on +24V output

The Enable/Reset terminal will not reset an O.Ld1 trip. Use the Stop/Reset key.

OUL.d

I x t overload

Reduce motor current

hot

Heatsink/IGBT temp is high

Reduce ambient temperature or reduce motor current

br.rS

Braking resistor overload

See Advanced user guide

EEF

Internal drive EEPROM failure

Possible loss of parameter values

PH

Input phase imbalance or

One of the input phases has become disconnected from the drive

input phase loss

rS

Failure to measure motors

Motor too small for drive

stator resistance

Motor cable disconnected during measurement

O.cL

Overload on current loop input

Input current exceeds 25mA

tr HF ##

Hardware Fault

The drive has detected a hardware problem, verify wiring is correct. This cannot be

fixed in the field, replace the drive.

HF 05 trip

No signal from DSP at start up

HF 06 trip

Unexpected Interrupt

HF 07 trip

Watchdog failure

HF 08 trip

Interrupt crash (code overrun)

HF 11 trip

Access to the EEPROM failed

HF 20 trip

Power stage - code error

HF 21 trip

Power stage - unrecognized frame size

HF 22 trip

Ol failure at power up

HF 25 trip

DSP Communications failure

HF 26 trip

Soft start relay failed to close, or soft start monitor failed or braking IGBT short circuit at power up

HF 27 trip

Power stage thermistor fault

HF 28 trip

DSp software overrun

HF xx trip

HF 1-4, 9-10,12-19,23,24,29,30 Are not used

Barrier Glider™ Inverter Program Instructions

When in Status mode, pressing and holding the

“M” MODE

key for 2 seconds will change the display from displaying a speed indication to

displaying load indication and visa versa.

Pressing and releasing the

“M” MODE

key will change the display from status mode to parameter view mode. In parameter view mode, the left

hand display flashes the parameter number and the right hand display shows the value of that parameter.

Pressing and releasing the

“M” MODE

key again will change the display from parameter view mode to parameter edit mode. In parameter edit

mode, the right hand display flashes the value in the parameter being shown in the left hand display.

Pressing the

“M” MODE

key in parameter edit mode will return the drive to the parameter view mode. If the

“M” MODE

key is pressed again then

the drive will return to status mode, but if either of the

“UP”

or

“DOWN”

keys are pressed to change the parameter being viewed before the

“M”

MODE

key is pressed, pressing the

“M” MODE

key will change the display to the parameter edit mode again. This allows the user to very easily

change between parameter view and edit modes whilst commissioning the drive.

"WARNING: Consult factory before changing any parameters not listed in this table."

Parameter Number

Name

Default Value

New Value

Units

00.10

Security Status

L1

L3

00.19

Closing Speed

0

30

s/100 Hz

00.20

Open Speed

0

60

S/100 Hz

00.61

Torque Detection Level

0

23

%

Barrier Glider - Status Modes

Left Display Status

Explanation

rd

Drive ready

The drive is enabled and ready for a start command. The output bridge is inactive.

ih

Drive inhibited

The drive is inhibited because there is no enable command, or a coast to stop is in

progress or the drive is inhibited during a trip reset.

Er

Drive has tripped

The drive has tripped. The trip code will display in the right hand display.

dC

Injection braking

DC injection braking current is being applied to the motor.

Fr

Drive output frequency in Hz

SP

Motor speed in RPM

Ld

Load current as a % of motor rated load current

A

Drive output current per phase in A