Installation and opreating instructios for tor-

sionally stiff gear couplings

RDZ…DTO/…DFO

E 06.705

As of: 12.08.2020

Version: 02

Signed: SCCE

Checked: SCHW

No. of pages: 21 Page: 11

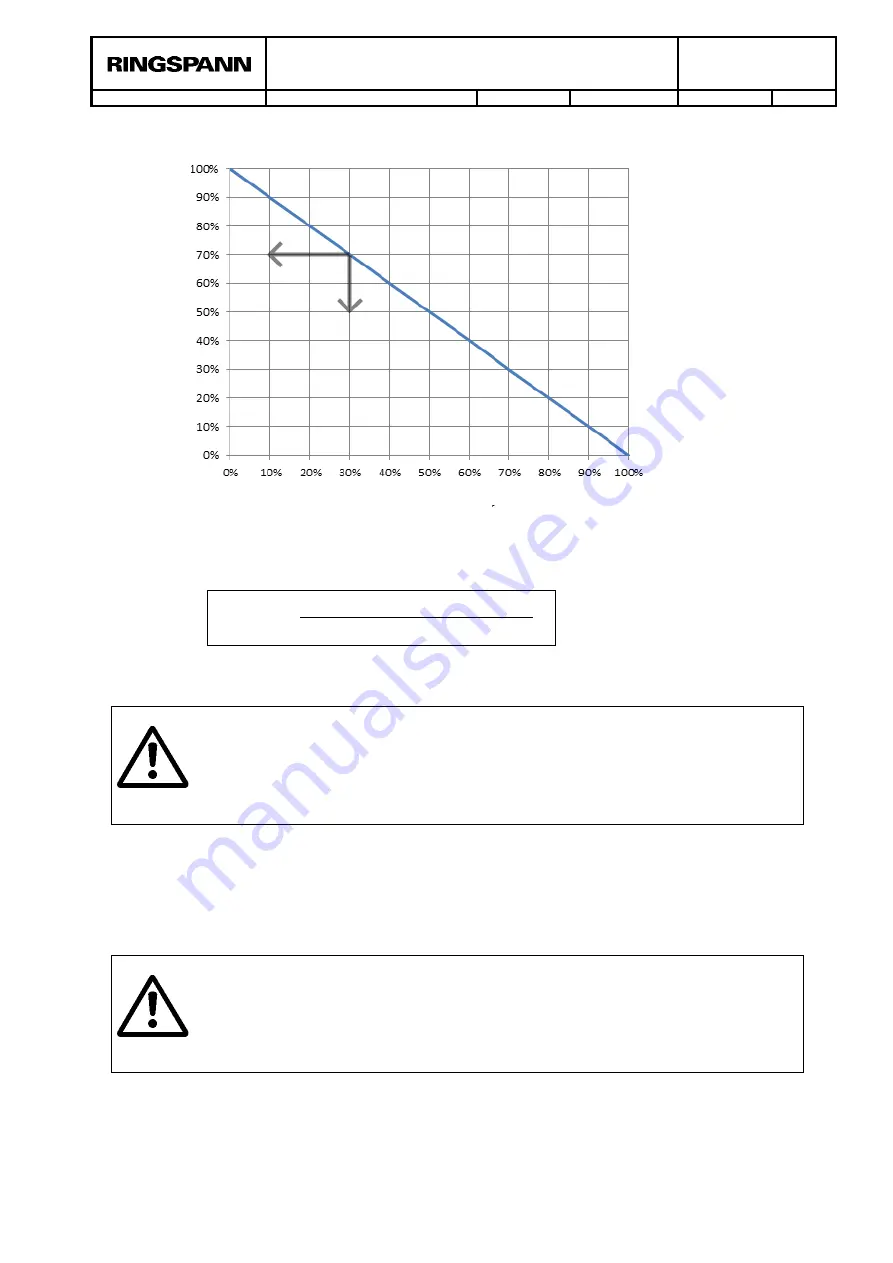

Figure 7.2: Misalignment combination

The misalignment as a percentage is calculated as follows:

7.3. Hub bore specifcations

When boring, or reboring the hub, it must be ensured that:

- the hub is precisely aligned,

- the form and positional tolerances in accordance with DIN ISO 286 are adhered to (see

figure 7.3).

Life-threatening danger!

The max. permissible bore diameters specified in table 7.3 may not be ex-

ceeded. If the permissible values are exceeded, the hub could crack during op-

eration. This could cause life-threatening danger due to flying parts.

Attention!

Never clamp onto the sealing surface! The operator bears the sole responsibil-

ity for any damages that may occur due to defective rework on the unbored /

roughly bored coupling parts.

∆𝐾[%] =

∆𝐾

𝑚𝑎𝑥. 𝑝𝑒𝑟𝑚𝑖𝑠𝑠𝑖𝑏𝑙𝑒 𝑚𝑖𝑠𝑎𝑙𝑖𝑔𝑛𝑚𝑒𝑛𝑡

∗ 100

Radial misalignment

ΔK

r

A

ng

u

la

r

m

is

a

li

gn

m

e

nt

Δ

K

w