- 19 -

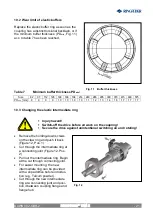

After the sense of rotation test, cut through a new intermediate ring at a connecting part

and fit it between coupling hub and flange.

To obtain an easier mounting one can provide the new elastic intermediate ring with a slip

additive before its introduction (e.g. talcum powder).

Attention!

The bearing surface of the claw ring and flange hub must be clean, dry and grease-

free. Balanced parts are position marked to each other.

Mount the claw ring into its marked

position. When doing this pay atten-

tion also that the parts not tilt when

being joined to the centering seat.

Slightly tighten the screws uniformly.

Tighten the claw ring threaded joint

with the tightening torque M

A

stipu-

lated in table 6 (Figure 10).

Check the alignment of the coupling

according to the specifications in „8

Coupling adjustment”.

Table 6

Tightening torques M

A

of the bolting of the claw ring:

Size

82 97 112 128 148 168 194 214 240 265 295 330 370 415 480 575

DIN 912- 8.8

M6 M6 M8 M8 M10 M10 M10

DIN 912-10.9

M12 M12 M14 M14 M16 M16 M16 M20 M20

M

A

[Nm]

10 10 25 25 49 49 49 125 125 200 200 310 310 310 610 610

Observe reduced tightening torques for the bolting of the claw ring if coupling parts

are phosphated and oiled!

Size

82 97 112 128 148 168 194 214 240 265 295 330 370 415 480 575

DIN 912- 8.8

M6 M6 M8 M8 M10 M10 M10

DIN 912-10.9

M12 M12 M14 M14 M16 M16 M16 M20 M20

M

A

[Nm]

8,3 8,3 20 20 40 40 40 100 100 160 160 240 240 240 490 490

Fig. 10

RINGFEDER

®

TNM E

BAWN 002-GBR-2