- 16 -

Table 5

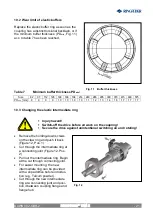

Operating faults and their possible causes:

Trouble

Cause

Risk Warning

Correction

Irregular

running

noises/

vibrations

Alignment fault Considerable

increase in

coupling tempera-

ture. Premature

wear of elastic

buffers. Increased

reaction forces act

on connected

machines.

-

Disconnect drive

-

Remove cause for alignment fault

-

Re-align coupling

-

Inspect elastomer for wear

Elastomer

worn out

Coupling claws

strike against

each other. Spark

formation, claw

fracture, in-

creased reaction

forces.

-

Disconnect drive

-

Check coupling components for

damages and replace parts, if nec-

essary

-

Replace elastomer

Unbalance

Considerable

increase in

coupling tempera-

ture. Premature

wear of elastic

buffers. Increased

reaction forces act

on connected

machines

-

Disconnect drive

-

Verify balance state of plant compo-

nents and correct it, if necessary

-

Inspect elastomer for wear

Loose

screw

connec-

tions

Flying off parts

can cause serious

injuries and

considerable

damages.

-

Disconnect drive

-

Check coupling parts for damages,

replace parts, if necessary

-

Verify alignment of coupling

-

Tighten screws to the specified

tightening torque and secure them

against working loose, if necessary,

-

Inspect elastomer for wear

Premature

wear of

elastomer

Alignment fault Considerable

increase in

coupling tempera-

ture. Increased

reaction forces act

on connected

machines.

-

Disconnect drive

-

Remove cause for alignment fault

-

Re-align coupling

-

Inspect elastomer for wear

RINGFEDER

®

TNM E

BAWN 002-GBR-2