ASSEMBLY INSTRUCTIONS

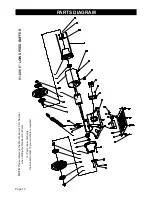

INSTALL THE BUFFING WHEELS

1. Remove the plastic protective sleeves from the

arbor shafts, if present.

2. Slide the Spacer onto the arbor shaft. FIG. E.

NOTE:

Spacers are not required when mount

-

ing several, or thicker, wheels are mounted onto

the shaft. Their purpose is to set the flanges

and wheel(s) away from the step in the arbor far

enough so that the arbor nuts can be threaded

onto the arbor to secure the wheels in place.

3. Slide the Inner Flange onto the shaft. The ‘cup’

side should be facing towards the threaded end

of the shaft, and will be against the buffing wheel

when it is installed in step 4.

4. Slide the Buffing Wheel onto the shaft and butt

it against the inner flange.

5. Slide the Outer Flange onto the shaft and butt it

against the buffing wheel. The ‘cup’ side should be

facing towards the buffing wheel.

Page 10

6. Thread the Arbor Nut onto the shaft to secure

the buffing wheel firmly in place. The places

pressure against the flanges which press against

the buffing wheel to hold it in place on the shaft.

NOTE:

The left hand arbor hex nut is left hand

threaded and is installed by rotating it coun

-

terclockwise onto the threaded shaft. The right

hand arbor hex nut is right hand threaded and is

linstalled by rotating it clockwise onto the shaft.

7. Install the second buffing wheel following the

same procedure outlined above.

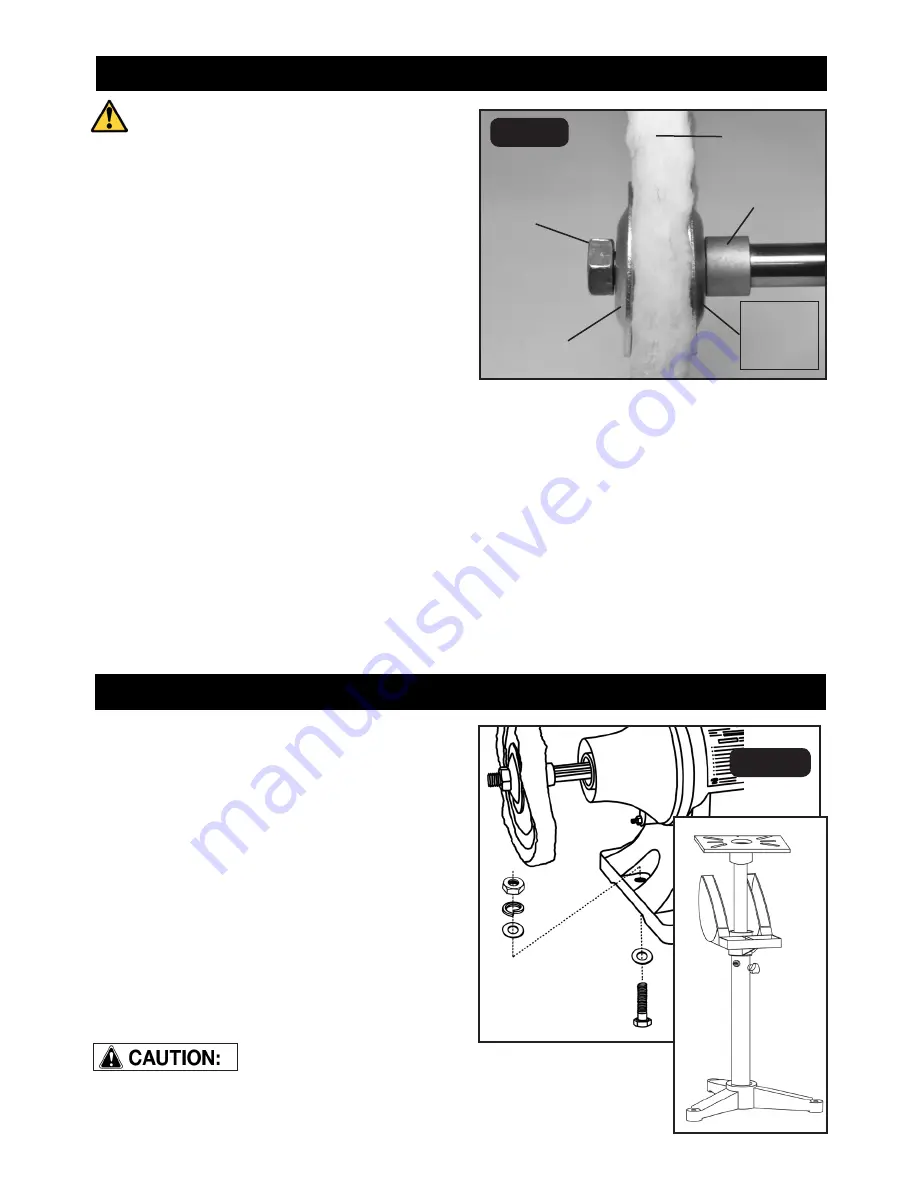

INSTALLATION

PERMANENT MOUNTING

Use the mounting holes in the base of the

machine to firmly attach the Buffer to a solid work

surface or stand (mounting hardware and stand

not included). See Figure F.

To avoid serious injury, secure the Buffer to a

solid work surface. If the Buffer is not permanently

mounted to a work surface, and remains portable,

the Buffer’s base should be temporarily clamped

to a table or board/plywood. Make sure that the

clamps do not interfere with the buffing wheels or

hinders the movement of the user and the material

during use.

FIG. F

If the Buffer is not securely mounted, it will have the

ability to move or tip over during buffing operations, and possibly cause the

operator’s fingers to contact the rotating wheels, damage to the work piece

being buffed, or damage the buffer and any surrounding shop items.

THE BUFFER MUST NOT BE PLUGGED IN

AND THE POWER SWITCH MUST BE IN THE

OFF POSITION UNTIL ASSEMBLY IS COMPLETE

.

SPACER

INNER

FLANGE

OUTER

FLANGE

BUFFING

WHEEL

LH NUT

FIG. E

HARDWARE

RECOMMENDED

FOR MOUNTING

THE BUFFER

WORK

STAND