Start-up, calibration and operation of the burner

20008423

31

GB

5.7

Final calibration of the pressure switches

5.7.1

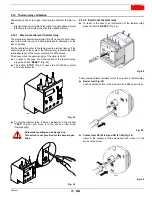

Air pressure switch

Adjust the air pressure switch after having performed all other

burner adjustments with the air pressure switch set to the start

of the scale (Fig. 35).

With the burner operating at min. output, increase adjustment pres-

sure by slowly turning the relative dial clockwise until the burner

locks out.

Then turn the dial anti-clockwise by about 20% of the set point and

repeat burner starting to ensure it is correct.

If the burner locks out again, turn the dial anti-clockwise a little bit

more.

As a rule, the air pressure switch must prevent the air

pressure from lowering below 80% of the adjustment

value as well as preventing the CO in the fumes from

exceeding 1% (10,000 ppm).

To check this, insert a combustion analyser into the

chimney, slowly close the fan suction inlet (for ex-

ample with cardboard) and check that the burner

locks out, before the CO in the fumes exceeds 1%.

On

RS 300-400-500/E burners

the air pressure switch is fitted

in a "differential" mode, that is, with two pipes connected to the

specific pressure test points “+” and “-” 22) and 23) (Fig. 5).

5.7.2

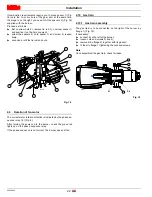

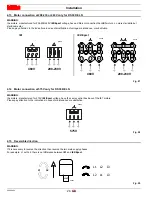

Maximum gas pressure switch

Adjust the maximum gas pressure switch after having performed

all other burner adjustments with the maximum gas pressure

switch set to the end of the scale (Fig. 39).

With the burner operating at MAX output, reduce the adjustment

pressure by slowly turning the adjustment dial anticlockwise until

the burner locks out.

Then turn the dial clockwise by 0.8” WC and repeat burner firing.

If the burner locks out again, turn the dial again clockwise by

0.4” WC.

5.7.3

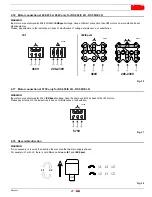

Minimum gas pressure switch

Adjust the minimum gas pressure switch after having performed

all the other burner adjustments with the pressure switch set at

the start of the scale (Fig. 40).

With the burner operating at MAX output, increase adjustment

pressure by slowly turning the relative dial clockwise until the burn-

er locks out.

Then turn the dial anti-clockwise by 0.8” WC and repeat burner

starting to ensure it is uniform.

If the burner locks out again, turn the dial anti-clockwise again by

0.4” WC.

ATTENTION

Fig. 39

D9272

Fig. 40

D9290