20008423

28

GB

Start-up, calibration and operation of the burner

5.1

Notes on safety for the first start-up

The first start-up of the burner must be carried out by

qualified personnel, as indicated in this manual and in

compliance with the standards and regulations of the

laws in force.

Check the correct working of the adjustment, command

and safety devices.

5.2

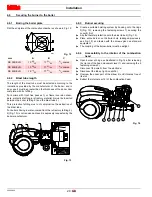

Adjustments before first firing

Adjustment of the combustion head has been illustrated in Fig.

16 and Fig. 18.

In addition, the following adjustments must also be made:

Open manual valves up-line from the gas train.

Adjust the minimum gas pressure switch (Fig. 33) to the start

of the scale.

Adjust the maximum gas pressure switch (Fig. 34) to the end

of the scale.

Adjust the air pressure switch (Fig. 35) to the start of the scale.

Purge the air from the gas line.

Continue to purge the air (we recommend using a plastic tube

routed outside the building) until gas is smelt.

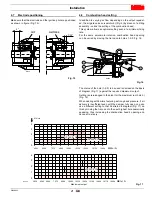

Fit a U-type manometer (Fig. 36) to the gas pressure test

point on the sleeve.

The manometer readings are used to calculate MAX. burner

power using the table on pag. 23.

Connect two lamps or testers to the two gas line solenoid

valves to check the exact moment at which voltage is sup-

plied.

This operation is unnecessary if each of the two solenoid

valves is equipped with a pilot light that signals voltage pass-

ing through.

Before starting up the burner it is good practice to adjust the gas

train so that ignition takes place in conditions of maximum safe-

ty, i.e. with gas delivery at the minimum.

5

Start-up, calibration and operation of the burner

WARNING

WARNING

Fig. 33

D9290

Fig. 34

D9272

Fig. 35

D3854

D3100

Fig. 36