20159324

30

GB

Start-up, calibration and operation of the burner

6.9

Burner start-up cycle diagnostics

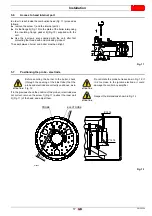

During start-up, indication is according to the colour code table

(Tab. G).

Tab. G

Off

Yellow

Green

Red

6.9.1

Resetting of control box and diagnostics use

The control box supplied features a diagnostics function, through

which any causes of malfunctioning can be easily identified

(indicator:

RED LED

).

To use this function, you must wait at least 10 seconds once it

has entered the safety condition (

lockout

), and then press the

reset button.

The control box generates a sequence of pulses (1 second

apart), which is repeated at constant 3-second intervals.

Once you have seen how many times the light blinks and

identified the possible cause, the system must be reset by

holding the button down for 1 - 3 seconds.

Tab. H

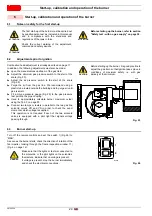

Below is a list of the possible methodologies for carrying out the

resetting of the control box and for using the diagnostics.

6.9.2

Control box reset

To reset the control box, proceed as follows:

–

Hold the button down for between 1 and 3 seconds.

The burner starts up again, 2 seconds after the button is

released.

If the burner does not restart, make sure the limit thermostat

is closed.

6.9.3

Visual diagnostics

Indicates the type of burner malfunction causing lockout. To view

diagnostics, proceed as follows:

–

Press and hold the button for more than 3 seconds from the

steady red LED condition (burner lockout).

A yellow light blinks to tell you the operation is done.

–

Release the button once the light has blinked. The number of

blinks indicates the reason for the malfunctioning (refer to the

coding in Tab. M on page 36).

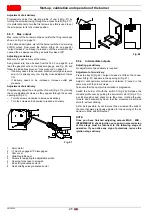

6.9.4

Software diagnostics

Provides an analysis of the life of the burner, through optical

connection with a PC showing the working hours, number and

types of lockout, control box serial number etc.

To view diagnostics, proceed as follows:

–

Press and hold the button for more than 3 seconds from the

steady red LED condition (burner lockout).

A yellow light blinks to tell you the operation is done.

–

Release the button for 1 second and then press again for

over 3 seconds until the yellow light blinks again.

–

Once the button is released, the red LED will flash

intermittently with a higher frequency: it will then be possible

to insert the optical connection.

Once the operations are done, the control box’s initial status must

be restored using the resetting procedure described above.

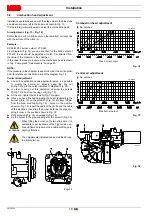

Tab. I

The sequence of led pulses issued by the control box identifies

the possible types of malfunction, which are listed in the table

Tab. M on page 36.

Sequences

Colour code

Pre-purging

Ignition phase

Operation, flame OK

Operation with weak flame signal

Electrical supply below

~ 170V

Lockout

Extraneous light

RED LED lit

wait for at least 10s

Lockout

Press reset for > 3s

Pulses

3s

interval

Pulses

PRESSURE ON THE BUTTON

STATE OF CONTROL BOX

Between 1 and 3 seconds

Reset of the control box without displaying the visual diagnostics.

More than 3 seconds

Visual diagnostics of the lockout condition:

(Led pulses at 1-second intervals).

More than 3 seconds starting from the

condition of visual diagnostics

Diagnostic software using an optical interface and PC

(possibility of displaying the hours the machine has been running, faults, etc.)

Содержание RS 25/M C05

Страница 2: ...Translation of the original instructions...

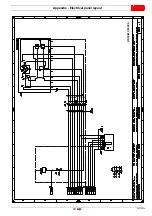

Страница 44: ...20159324 42 GB Appendix Electrical panel layout RS 25 35 M C05 1Ph...

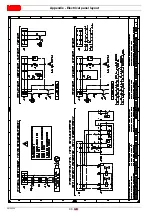

Страница 45: ...43 20159324 GB Appendix Electrical panel layout RS 35 M C05 3Ph...

Страница 50: ......

Страница 51: ......