20159324

16

GB

Installation

5.4

Operating position

5.5

Preparing the boiler

5.5.1

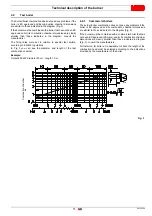

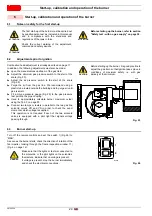

Boring the boiler plate

Pierce the closing plate of the combustion chamber, as in Fig. 9.

The position of the threaded holes can be marked using the

thermal insulation screen supplied with the burner.

Tab. D

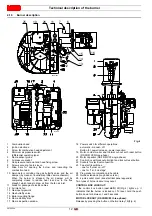

5.5.2

Blast tube length

The length of the blast tube must be selected according to the

indications provided by the manufacturer of the boiler, and in any

case it must be greater than the thickness of the boiler door

complete with its fettling.

The range of lengths available, L (mm), is as follows:

Tab. E

For boilers with front flue passes 13) or flame inversion chamber,

a protection in refractory material 11) must be inserted between

the boiler fettling 12) and the blast tube 10).

This protective fettling must not compromise the extraction of the

blast tube.

For boilers with a water-cooled front piece, a refractory lining 11)-

12)(Fig. 10) is not necessary, unless expressly requested by the

boiler manufacturer.

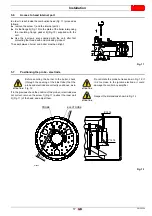

5.5.3

Securing the burner to the boiler

Separate the combustion head from the rest of the burner

(Fig. 10):

Remove the cover.

Disengage the articulated coupling 4) from the graduated

sector 5)

Remove the screws 2) from the two slide bars 3).

Remove the screw 1) and draw the burner back on the slide

bars 3) by about 100mm.

Disconnect the probe and electrode cables and then slide

the burner completely out of the slide bars.

ATTENTION

The burner is set up to operate only in

positions

1, 2, 3

and

4

Installation

1

is preferable, as it is the only

one that allows the maintenance operations

as described in this manual.

Installations

2, 3

and

4

permit operation but

make maintenance and inspection of the

combustion head more difficult.

DANGER

Any other position could compromise the

correct operation of the appliance.

Installation

5

are forbidden for safety

reasons.

Fig. 8

2

3

4

5

1

D3928

mm

A

DF

Ø

RS 25/M C05

160

224

M 8

RS 35/M C05

160

224

M 8

mm

RS 25/M C05

RS 35/M C05

Standard

230

198

Elongated

365

333

Fig. 9

20150238

Provide an adequate lifting system.

ATTENTION

The seal between burner and boiler must be

airtight.

Fig. 10

D3834

Содержание RS 25/M C05

Страница 2: ...Translation of the original instructions...

Страница 44: ...20159324 42 GB Appendix Electrical panel layout RS 25 35 M C05 1Ph...

Страница 45: ...43 20159324 GB Appendix Electrical panel layout RS 35 M C05 3Ph...

Страница 50: ......

Страница 51: ......