29

20159324

GB

Start-up, calibration and operation of the burner

6.8

Burner operation

6.8.1

Burner start-up

0s:

TL thermostat/pressure switch closes.

2s:

Start of electrical control box programme. Servomotor

starts: turn 90° to the left, i.e. until the contact on cam I in-

tervenes (Fig. 28 on page 26).

26s:

The air damper arrives to the MAX. output position.

Fan motor starts up.

Start of the pre-purging phase.

57s:

the servomotor rotates towards the right, as far as the an-

gle set on cam III (Fig. 28 on page 26) for the MIN output.

77s:

The air damper and gas butterfly valve assume the MIN

output position (with cam III)(Fig. 28 on page 26) at 15°.

92s:

Ignition electrode strikes a spark.

The safety valve VS opens, along with the adjustment

valve VR, quick opening. The flame is ignited at a low out-

put level, point A (Fig. 33).

Delivery is then progressively increased, with the valve

VR opening slowly up to MIN. output, point B (Fig. 33).

94s:

The spark goes out.

118s: The starting cycle comes to an end.

6.8.2

Operation

Burner without modulating operation kit

Once the start-up cycle is completed, the servomotor command

moves on to the TR thermostat/pressure switch that controls the

pressure or the temperature in the boiler, point C (Fig. 33).

(The electrical control box still continues to check the presence of

the flame and the correct position of the air and gas pressure

switches).

–

If the temperature or the pressure is low, the reason why the

thermostat/pressure switch TR is in the output request posi-

tion, the burner progressively increases the output up to the

MAX value (section C-D)(Fig. 33).

–

If, then, the temperature or the pressure increases up to the

TR switching, the burner gradually decreases the output

down to the MIN value, (section E-F)(Fig. 33).

The sequence repeats endlessly.

–

The burner locks out when the heat request is less than the

heat supplied by the burner at MIN output, (section G-H).

The TL thermostat/pressure switch opens, and the servomo-

tor returns to angle 0°.

The air damper closes completely to reduce heat losses to a

minimum.

Burner with modulating operation kit

See manual enclosed with the adjuster.

6.8.3

Ignition failure

If the burner does not switch on, it goes into lockout within 3s of

the gas valve opening.

6.8.4

Burner flame goes out during operation

If the flame should accidentally go out during operation, the burn-

er will lock out within 1s.

ATTENTION

In the event the burner stops, in order to prevent

any damage to the installation, do not unblock the

burner more than twice in a row.

If the burner locks out for a third time, contact the

customer service.

DANGER

In the event there are further lockouts or faults

with the burner, the maintenance interventions

must only be carried out by qualified, authorised

personnel, in accordance with the contents of this

manual and in compliance with the standards and

regulations of current laws.

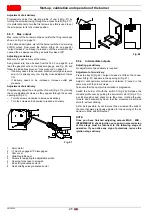

Fig. 33

D3857

STANDARD IGNITION

(no. = seconds from instant 0)

Fig. 34

D3858

IGNITION FAILURE

Содержание RS 25/M C05

Страница 2: ...Translation of the original instructions...

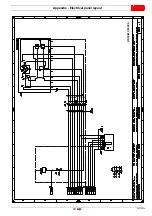

Страница 44: ...20159324 42 GB Appendix Electrical panel layout RS 25 35 M C05 1Ph...

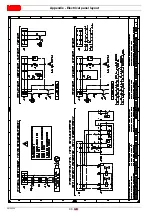

Страница 45: ...43 20159324 GB Appendix Electrical panel layout RS 35 M C05 3Ph...

Страница 50: ......

Страница 51: ......