Installation

13

20020804

4.5

Securing the burner to the boiler

4.5.1

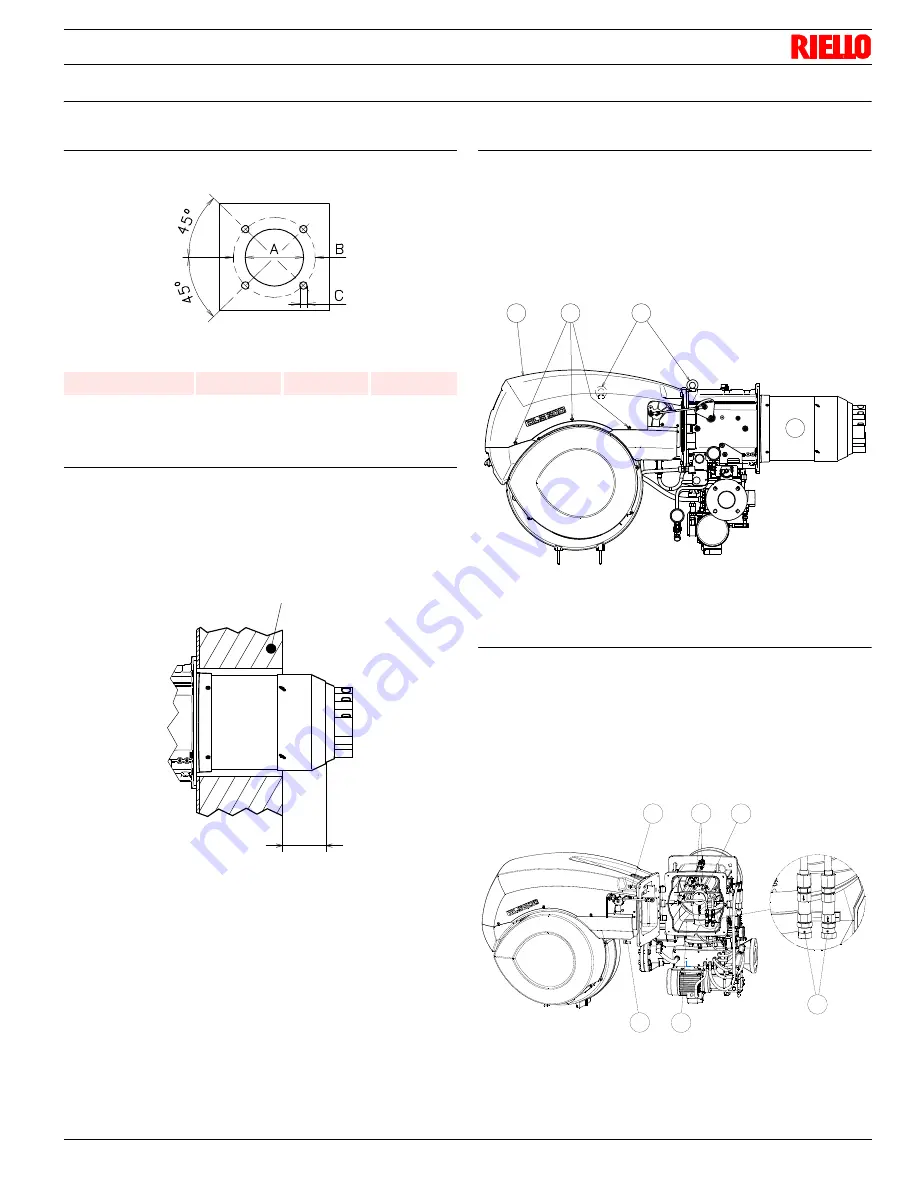

Boring the boiler plate

Drill the combustion chamber locking plate as shown in (Fig. 9).

Tab. 4

4.5.2

Blast tube length

The length of the blast tube must be selected according to the

indications provided by the manufacturer of the boiler, and in

any case it must be greater than the thickness of the boiler door

complete with its fettling (the head should not jut out more than

4÷5 inch).

4.5.3

Burner securing

Create a suitable hoisting system by hooking onto the rings

4), removing the fastening screws 1) securing the cover 2)

first.

Slip the thermal protection onto the blast tube 3).

Place entire burner on the boiler hole (arranged previously,

see Fig. 9), and fasten with the screws given as standard

equipment.

The coupling of the burner-boiler must be airtight.

4.5.4

Accessibility to the interior of the combustion

head

Open burner at hinge (see Fig. 12) after removing the 4

screws 1).

Disconnect the wires 2) from the electrodes.

Disconnect the oil pipes by unscrewing the two connectors 3).

Note: While unscrewing, some fuel may leak out.

Unscrew the under part of the elbow 4) until it comes free of

its slot.

Extract the internal part 5) of the combustion head.

mm

A

B

C

RLS 800/E US1

17 5/16“

19 31/64“

45/64 W

Fig. 9

D455

4 ÷ 6 "

REFRACTORY MATERIAL

D10002

Fig. 10

REFRACTORY MATERIAL

1

4

2

3

D10003

Fig. 11

Fig. 12

1

4

1

2

5

3

A

D3508

Содержание RLS Series

Страница 2: ......

Страница 34: ...20020804 32 Appendix Electrical panel layout ...

Страница 35: ...Appendix Electrical panel layout 33 20020804 ...

Страница 36: ...20020804 34 Appendix Electrical panel layout ...

Страница 37: ......

Страница 38: ......

Страница 39: ......