Start-up, calibration and operation of the burner

27

20045163

GB

The eccentric setting should be carried out by loosening screws 7),

and turning the screw 5) to obtain the desired eccentricity.

➤

Turn clockwise, screw 5) to increase the eccentricity, increas-

ing the difference between the min. and max. capacity of the

nozzle;

➤

turn counter-clockwise, screw 5) to decrease the eccentricity

and, consequently the difference between the min. and max.

capacity of the nozzle.

When the setting is carried out, verify manually that no slow-down

occurs between 0° and 130° and that the maximum and minimum

pressures correspond to those chosen as per diagrams (Fig. 33).

If you wish to check the delivery capacity of the nozzle, open the

burner, attach the nozzle, simulate the start-up and then proceed

with observing of the maximum and minimum pressures of the fuel.

If at the maximum capacity of the nozzle (maximum pressure in the

return line) pressure fluctuations are detected on the gauge 1),

slightly decrease the pressure in the return line until they are com-

pletely eliminated.

5.4

Burner start-up

Feed electricity to the burner via the disconnecting switch on the

boiler panel.

Close the thermostats/pressure switches, set the parameters on

the RWF 40 regulator.

Please refer to the spacific manual for this operation.

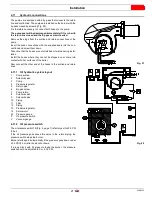

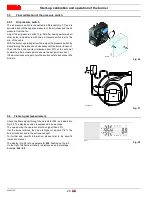

Turn the switch of Fig. 35 to position “LOCAL”.

WARNING

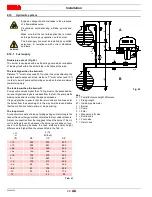

the proper setting of the eccentric 6) is possible

when its operation field follows the servomotor op-

eration field (20° ÷ 130°): so, that every variation of

the servomotor position corresponds to a pressure

variation.

WARNING

Do not let the piston bottom out repeatedly: the stop

ring 3)(Fig. 34) determines the max. stroke.

DANGER

Make sure that the lamps or testers connected to

the solenoids, or indicator lights on the solenoids

themselves, show that no voltage is present. If volt-

age is present, stop the burner immediately and

check the electrical wiring.

WARNING

When the burner starts, check the direction of the

motor rotation, as indicated in (Fig. 35).

As the burner is not fitted with a device to check the

sequence of the phases, the motor rotation may be

incorrect. As soon as the burner starts up, go in

front of the cooling fan of the fan motor and check it

is rotating anticlockwise. See Fig. 35.

If this is not the case:

➤

place the switch of Fig. 35 in position "0" and

wait for the control box to carry out the

switchoff phase;

➤

disconnect the electrical supply from the

burner;

➤

invert the phases on the three-phase power

supply

WARNING

For the start-up procedure and the parameters

calibration, refer to the specific instruction man-

ual of the LMV37... electronic cam supplied with

the burner.

Fig. 35

D12233

Содержание RL 70/E

Страница 2: ......

Страница 35: ...Appendix Spare parts 33 20045163 GB A Appendix Spare parts 74 75 76 80 ...