2374

6

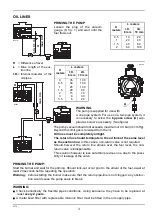

PRESSURE:

12 bar:

pressure suitable for light oil in most cases.

14 bar:

improves flame retention; it is therefore suitable for ignitions at low temperatures.

FOR KEROSENE DECREASE PRESSURE

8 bar:

pressure suitable for kerosene in most cases.

10 bar:

maximum pressure for kerosene.

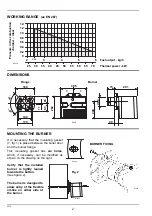

COMBUSTION HEAD SETTING

This is done when fitting the nozzle, with the blast tube removed.

It depends on the output of the burner and is carried out by rotating the regulating rod, till the terminal

plane of the blast tube is level with the set-point, as indicated in the schedule.

AIR DAMPER ADJUSTMENT

The regulation of the air-rate is made by adjusting the air

damper (1), after loosing the screws (2).

The settings indicated in the schedule refer to the burner

with its metal cover fitted and the combustion chamber

with “zero” depression.

These regulations are purely indicative. Each installation

however, has its own unpredictable working conditions: actu-

al nozzle output; positive or negative pressure in the

combustion-chamber, the need of excess air, etc. All these

conditions may require a different air-damper setting.

It is important to take account of the fact that the air

output of the fan differs according to whether the

burner has its metal cover fitted or not.

Therefore we recommended to proceed as follows:

– adjust the air damper as indicated in the schedule (4);

– mount the cover, simply by means of the upper screw;

– check smoke number;

– should it become necessary to modify the air output, remove the cover by loosening the screw,

adjust the air damper, remount the cover and finally recheck the smoke number.

2

3

Blast tube

Regulating rod

Shutter

Terminal plane of the blast tube

D5244

2

1

3

5

In the sketch on the left, the combustion

head is set for an output of 1.00 GPH at

12 bar

(for gas-oil)

or 1.25 GPH at 8 bar

(for kerosene).

The shutter is level with set-point

3

, as

required by the schedule at page 5

2

1

D5514

2

4