20163413

30

GB

Flame presence check

Check the level of the flame detection signal with the “Check

mode” function from the flame control: the LEDs from 2 to 6

indicate the flame signal level, respectively. See “LED indicator

and special function” on page 31.

Check Mode

With burner flame on:

hold the reset button on the flame control pressed for at

least 3 sec.;

the button colour will change from green to yellow;

each operating status signalling LED will be compared to

20% of the maximum brightness;

press the reset button again (<0.5sec) to reset the standard

operation of the signalling LEDs.Boiler

Clean the boiler as indicated in its accompanying instructions in

order to maintain all the original combustion characteristics in-

tact, especially the flue gas temperature and combustion cham-

ber pressure.

Gas leaks

Make sure that there are no gas leaks on the pipes between the

gas meter and the burner.

Gas filter

Replace the gas filter when it is dirty.

Combustion

If the combustion values measured before starting maintenance

do not comply with applicable legislation or do not indicate effi-

cient combustion, consult the Tab. K or contact our Technical

Support Service to implement the necessary adjustments.

It is advisable to set the burner according to the type of gas used

and following the indications in Tab. K.

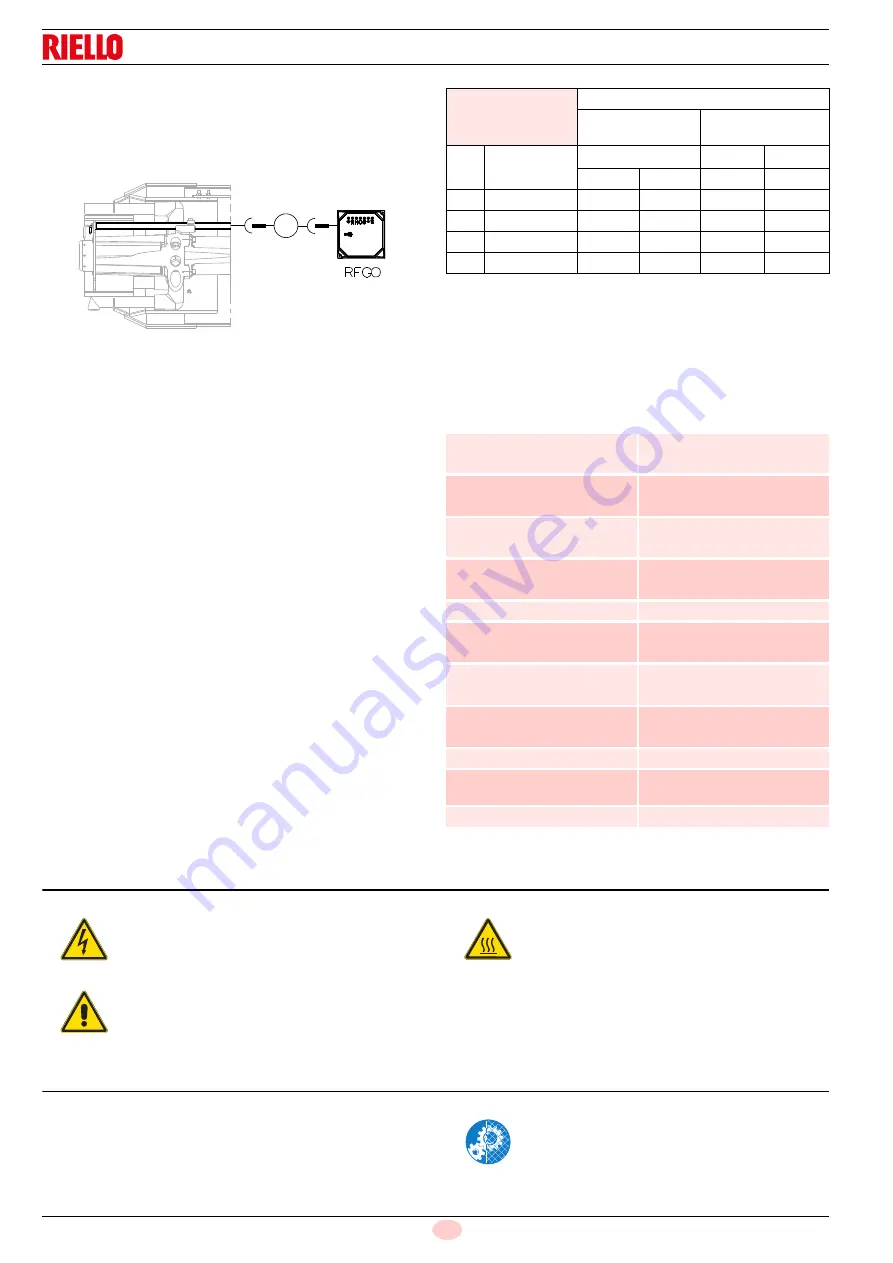

Tab. K

7.2.4

Safety components

The safety components should be replaced at the end of their life

cycle indicated in the Tab. L.

The specified life cycles do not refer to the warranty terms indi-

cated in the delivery or payment conditions.

Tab. L

7.3

Opening the burner

See “Access to head internal part” on page 18.

7.4

Closing the burner

Refit following the steps described but in reverse order; refit all

burner components as they were originally assembled.

-

μ A

+

Fig. 37

20156526

EN 676

Air excess

Max. output

1.2

Min. output

1.3

GAS

CO

2

theoretic

al max. 0% O

2

CO

2

% Calibration

CO

NO

X

= 1.2

= 1.3

mg/kWh mg/kWh

G 20

11.7

9.7

9.0

100

170

G 25

11.5

9.5

8.8

100

170

G 30

14.0

11.6

10.7

100

230

G 31

13.7

11.4

10.5

100

230

Safety component

Life cycle

Flame control

10 years or 250.000

operation cycles

Flame sensor

10 years or 250.000

operation cycles

Gas valves (solenoid)

10 years or 250.000

operation cycles

Pressure switches

10 years or 250.000

operation cycles

Pressure adjuster

15 years

Servomotor (electronic cam)

10 years or 250.000

operation cycles

Oil valve (solenoid)

10 years or 250.000

operation cycles

Oil regulator

10 years or 250.000

operation cycles

Pipes/ oil fittings (metallic)

10 years

Flexible hoses (if present)

5 years or 30.000

pressurised cycles

Fan impeller

10 years or 500.000 start-ups

DANGER

Disconnect the electrical supply from the burner

by means of the main system switch.

DANGER

Close the fuel interception tap.

Wait for the components in contact with heat

sources to cool down completely.

Carry out all maintenance work and mount the

casing again.

Содержание 20155875

Страница 2: ...Translation of the original instructions...

Страница 43: ...41 20163413 GB Appendix Electrical panel layout...

Страница 44: ...20163413 42 GB Appendix Electrical panel layout 0 0 1 0 1 2 0 3 0 1 0 1 1 0 0 0 0 0 40 4 4 0 0 1 2 0 1...

Страница 45: ...43 20163413 GB Appendix Electrical panel layout 0...

Страница 47: ...45 20163413 GB Appendix Electrical panel layout 0 0 1 2 2 2 2 2 2 2 0 0 2 0 2 0 1 2...

Страница 48: ...20163413 46 GB Appendix Electrical panel layout 0 1 2 1 3 4 56 4 6 4 6 5 4 786 9 3 1 2 78 0 0 2 2 2...