22

START CONDENS 25 IS

Twin pipes ø 80 with ducting Ø 50, Ø 60 and Ø 80

Thanks to the boiler characteristics, a flue gas discharge pipe ø

80 can be connected to the ducting ranges ø 50, ø 60 and ø 80.

9

For the ducting, you are advised to make a project calculation in

order to respect the relevant standards in force.

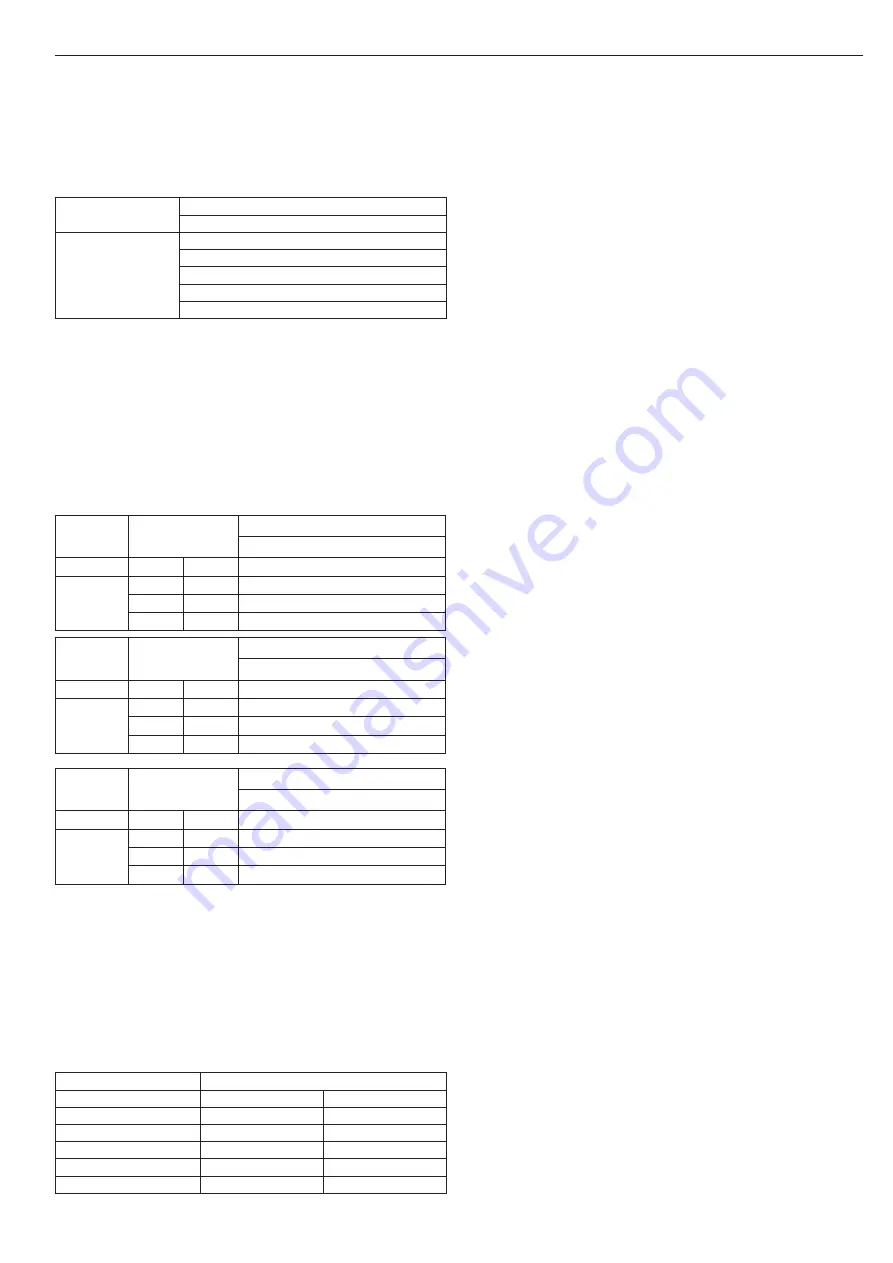

The table shows the standard configurations allowed.

T

able of standard pipe configurations

(*)

Air suction

1 bend - 90° ø 80

4.5 m pipe ø 80

Flue gas discharge

1 bend - 90° ø 80

4.5 m pipe ø 80

Reduction from ø 80 to ø 50 or from ø 80 to ø 60

90° stack base bend ø 50 or ø 60 or ø 80

For ducting pipe lengths see table

(*) Use flue gas system accessories in plastic (PP) for condensing

boilers: Ø50 and Ø80 H1 class and Ø60 P1 class.

The boilers are factory set to:

25 IS:

4.900 rpm (CH), 6.100 rpm (DHW) and the maximum length

that can be reached is 7 m for the ø 50 pipe, 25 m for the ø 60 pipe

and 75 m for the ø 80 pipe.

Should it be necessary to achieve greater lengths, compensate the

pressure drop with an increase in the r.p.m.of the fan, as shown in

the adjustments table, to ensure the rated heat input.

9

The minimum calibration is not modified.

Adjustments table

Fan rotations

r.p.m.

Pipes Ø 50 (*)

max length (m)

CH

DHW

25 IS

4.900

6.100

7

5.000

6.200

9

5.100

6.300

12 (**)

Fan rotations

r.p.m.

Pipes Ø 60 (*)

max length (m)

CH

DHW

25 IS

4.900

6.100

25

5.000

6.200

30

5.100

6.300

38 (**)

Fan rotations

r.p.m.

Pipes Ø 80 (*)

max length (m)

CH

DHW

25 IS

4.900

6.100

75

5.000

6.200

90

5.100

6.300

113 (**)

(*) Use flue gas system accessories in plastic (PP) for condensing

boilers.

(**) Maximum installable length ONLY with exhaust pipes in H1

class.

The configurations Ø 50, Ø 60 and Ø 80 show test data verified in

the laboratory.

In the case of installations that differ from those indicated in the

“standard configuration” and “adjustments” tables, refer to the

equivalent linear lengths below.

9

In any case, the maximum lengths declared in the booklet are

guaranteed, and it is essential not to exceed them.

COMPONENT

Linear equivalent in metres Ø80 (m)

Ø 50

Ø 60

Bend 45°

12,3

5

Bend 90°

19,6

8

Extension 0.5m

6,1

2,5

Extension 1.0m

13,5

5,5

Extension 2.0m

29,5

12

2.11 - System loading and emptying

Once the hydraulic connections have been carried out, fill the

system.

Loading

• Open by two or three turns the plugs of the lower (A - Fig. 13) and

upper (D - Fig. 13) automatic air vent valves; to allow a continuous

venting of the air, leave the plugs of valves A and D open (Fig. 13).

• Make sure the cold water inlet tap is open, turning it anti-clock-

wise.

• Open the filling tap (outside the boiler) until the pressure indicated

by the water pressure gauge is between 1 and 1.5 bar.

• Close the filling tap.

NOTE -

The venting of the

START CONDENS IS

boiler takes place

automatically via the two automatic vent valves A and D (Fig. 13),

the first positioned on the circulator and the second inside the air

distribution box.

NOTE -

If the venting phase proves difficult, proceed as described

in the paragraph "Eliminating the air from the heating circuit and

boiler".

Emptying

• Before starting emptying, switch off the electrical supply by turning

off the system's main switch

• Close the cold water inlet tap

• Close the shut-off devices of the heating system

• Manually loosen the system drain valve (B - fig. 13)

Eliminating the air from the heating circuit and boiler (fig. 14)

During the initial installation phase, or in the event of extraordinary

maintenance, you are advised to perform the following sequence of

operations:

• Open the lower automatic air vent valve cap (A - fig. 13) and leave

it open.

• Turn on the system filling tap

• Switch on the electricity supply to the boiler, leaving the gas tap

turned off.

• Activate a heat request via the ambient thermostat or the remote

control panel, so that the 3-way valve goes into heating mode.

• Activate a DHW request by open a tap for 30" per minute so that

the three-way valve cycles from heating to DHW and vice versa

for about ten times (in this situation, the boiler will go into alarm

due to lack of gas, therefore reset it whenever this is proposed).

• Continue the sequence until no more air is felt coming from the

air vent valve.

• Check the system pressure level is correct (the ideal level is 1

bar).

• Turn off the system filling tap.

• Turn on the gas tap and ignite the boiler.

2.12 - First commissioning preparation

Before the ignition and the functional testing of the

START CONDENS IS

boiler, it is necessary to:

• check that the system's fuel and water supply taps are open (fig. 15)

• check that the gas type and the power supply pressure are those

for which the boiler is designed

• make sure the cap on the vent valve is open

• check on the display that the pressure of the water circuit when

cold is between 1 bar and 1.5 bar and that the circuit is vented

• Check that the pre-loading of the expansion tank is adequate (see

the Technical data table)

• check that the electrical connections have been carried out cor-

rectly

• check that the combustion product outlet and air suction pipes

were adequately realised

• check that the circulator rotates freely because, especially after

long periods of non-operation, deposits and/or debris can prevent

free rotation.

9

Before loosening or removing the closing tap of the circulator,

protect the underlying electrical devices from possible water

leakage.