2318

1

GB

INDEX

1. BURNER DESCRIPTION

1.1 BURNER EQUIPMENT

Flange with insulating gasket . . . . No. 1

Screw and nuts for flange to be fixed to boiler . . . No. 2

Screw and nuts for flange . . . . . . No. 1

Flexible oil pipes with nipples . . . . . . . . . . . . . . . . No. 2

1.

BURNER DESCRIPTION. . . . . . . . . . . . . 1

1.1

Burner equipment. . . . . . . . . . . . . . . . . . . 1

2.

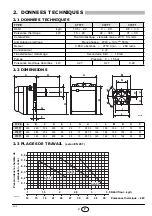

TECHNICAL DATA . . . . . . . . . . . . . . . . . 2

2.1

Technical data . . . . . . . . . . . . . . . . . . . . . 2

2.2

Overall dimensions. . . . . . . . . . . . . . . . . . 2

2.3

Working field . . . . . . . . . . . . . . . . . . . . . . 2

3.

INSTALLATION . . . . . . . . . . . . . . . . . . . . 3

3.1

Boiler fixing . . . . . . . . . . . . . . . . . . . . . . . 3

3.2

Fuel supply . . . . . . . . . . . . . . . . . . . . . . . 3

3.3

Hydraulic systems . . . . . . . . . . . . . . . . . . 4

3.4

Electrical wiring . . . . . . . . . . . . . . . . . . . . 5

4.

WORKING . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1

Combustion adjustment . . . . . . . . . . . . . . 6

4.2

Electrodes adjustment . . . . . . . . . . . . . . . 8

4.3

Flame detector adjustment . . . . . . . . . . . . 8

4.4

Fuel heating . . . . . . . . . . . . . . . . . . . . . . . 8

4.5

Burner start-up cycle. . . . . . . . . . . . . . . . . 9

5.

MAINTENANCE . . . . . . . . . . . . . . . . . . . . 9

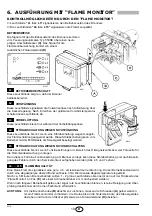

6.

MODEL WITH “FLAME MONITOR” . . . . . 10

7.

FAULTS / SOLUTIONS . . . . . . . . . . . . . . 11

Fig. 1

S7262

■

The burner meets protection level of IP 40, EN 60529.

■

Burner with CE marking in conformity with EEC directives: EMC 89/336/EEC, Low Voltage 73/23/EEC,

Machines 89/392/EEC and Efficiency 92/42/EEC.

■

DIN Certification No. : 5G383 / 94 (371T1) – 5G384 / 94 (372T1) – 5G385 / 94 (373T1) as EN 267.

■

BUWAL approval No. 192016.

One stage gas oil burner with blue flame and, therefore with low pollutant emissions (Nitric Oxide NOx,

Carbon monoxide CO and unburnt Hydrocarbons).

The burner has a device (compensator) which is integral with the air damper that sets the air output.

This device keeps the oxigen level as necessary for the combustion despite any changing of the room

temperature.

The dimension of the boiler’s combustion chamber must respond to specific

values, in order to guarantee a combustion with the lowest polluting

emissions rate.

The RIELLO Technical Service Personnel will be glad to give

you all the imformation for a correct matching of this

burner to the boiler.

1 – Oil pump

2 – Air damper adjustment

assembly

3 – Nozzle holder assembly

4 – Flange with insulating gasket

5 – Control-box

6 – Reset button with lock-out lamp

7 – Flame detector

8 – Temperature probe of the

compensator

Содержание 3737150

Страница 48: ......