9

9

I

NSTALLATION SEQUENCE WITH METALLIC PIT

1 - Ensure that the laying point of the STOPPER T does not fall within an impluvium area; in cases when, no matter why, this circumstance occurs, you

need to partially shelter the STOPPER T by means of a draining channel, equipped with covering grid.

2 - Dig a hole (using a miniature excavator or your hands) down to

1,30 m

in depth approx. A sector side shall be

1 m

approx.

3 - Ensure that the ground features a good water absorption (try by introducing about 40 litres of water and rate that the drain takes place in less than

30 minutes); otherwise, drain rain water through a pipe that is 60 mm in diameter connected to the sewer or, as an alternative, connected to a

pit (equipped with a pumpdown system, such as, for instance, an electric pump) being deeper than the cement pipe that collects and drains rain

water).

4 - Introduce gravel (grain 8 to 20 mm in diameter approx.) until a thickness of

30 cm

approx. is reached, taking care to compress it well to avoid eventual

“settling shrinkages”.

5 - Lay on the gravel the metallic pit complete with counter frame, paying attention that it has to be parallel to a plumb line and that the upper level of the

counter frame should be about 10 mm above the walking level (in order to reduce the flowing in of raining water).

Further on, please pay attention

on the counter frame setting considering the traffic direction (see drawing enclosed).

6 - Once the metallic pit is laid and if the bollard is equipped of inbuilt blinker and/or heating devices (optional articles), lay a flexible sheath with diameter

50 mm from the connection foreseen in metallic pit to the devices control panel.

7 - Introduce concrete all around the metallic pit thus made until its top is reached (about -10 cm from the walking level): Please pay attention that the

special clamps delivered with the counter frame are well placed. Once the metallic pit is laid, carry out the finish work using the same material as

the road course that is found all around the counter frame.

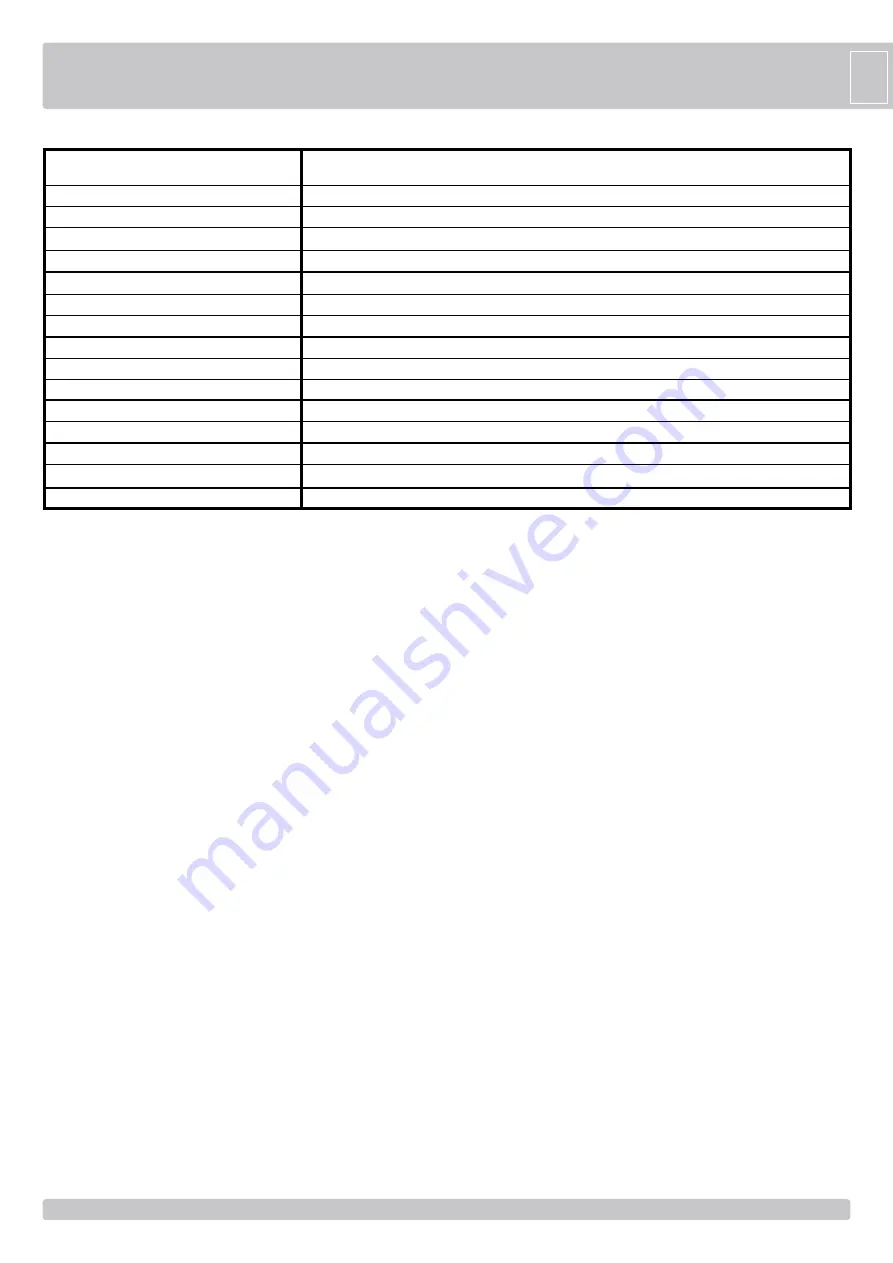

TECHNICAL DATA

Moving criteria

Moving cylinder

Moving cylinder treatment

Moving cylinder diameter

Moving cylinder height

Upper part of the cylinder (head)

Upper part of the cylinder treatment

Protection class

Work frequency - resistance class

Adesive reflecting strip

Temperature range of duty

Weight of the bollard with pit

Shock resistance

Breaking resistance

Pit dimensions

Single effect actuator

Steel FE37 - thickness 6 mm

Polyester powder painting - color metalized dark gray RAL7021

275 mm

600 mm

Anticorodal cemented alluminium

Polyester powder painting - color grey anthracite RAL9006

IP 67

Intensive use > 2.000.000 movings - 2.000 daily movings

Standard altezza 55 mm

-15°C +70°C - Optional: heating devices for temperature up to -25°C

kg 154

9.000 joule

120.000 joule

560 x 560 x H 1020 mm

STOPPER T 275 SEMI-AUTOMATIC - STEEL 6 mm

STOPPER T 275 SA INSTALLATION

G

B

Содержание AA51213

Страница 14: ...14 14 NOTES ...