52

2. Connect a manometer to the pressure tap.

3. Turn on the gas supply and operate the furnace at

100% and all other gas-fired units on the same gas

line as the furnace.

4. Note or adjust the supply-line pressure to give:

A. 5” - 10.5” w.c. for natural gas.

B. 11” - 13” w.c. for LP gas.

If your gas supply does not fall within these ranges,

contact your gas supplier to correct.

5. Shut off the gas at the manual gas valve and remove

the manometer.

6. Replace the supply-line pressure tap plug before turn -

ing on the gas.

7. Check unit for leaks using an approved leak detector.

Do NOT use a flame of any kind.

OUTLET/MANIFOLD GAS PRESSURE

MEASUREMENT/ADJUSTMENT

Rate adjustment is a combination of selecting the correct

orifices based on heating value and altitude

The outlet/manifold pressure on this modulation furnace is

capa ble of being adjusted at the maximum firing rate and

at the minimum firing rate using the same adjustment

wheel shown in Figure 41.

Note: Do not attempt to ad-

just the

outlet/manifold

pressure at intermediate inputs.

ADJUST MANIFOLD PRESSURE AT

MAXIMUM FIRING RATE

NOTE: HIGH FIRE MUST BE ADJUSTED BEFORE

LOW FIRE

1. With the gas to the unit shut off at the manual gas

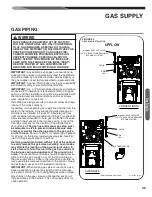

valve, remove the outlet/manifold pressure tap plug in

the gas valve. See Figure 39.

2. Install field supplied pressure tap to the outlet/manifold

tap in place of the plug. Connect the positive pressure

hose from a manometer to the pressure tap.

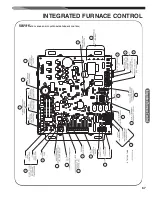

3. Set dip SW10 to the OFF position and dipswitch

SW11 to the ON position (this will force unit to operate

at Maximum Firing Rate only)

4. Remove all thermostat connections to the IFC and

jumper R to W1.

5. Turn gas manual shutoff valve to ON position.

6. Turn on furnace power supply.

7. After ignition, allow furnace to operate and complete

the pressure switch calibration before checking maxi -

mum firing rate outlet/manifold pressure.

Note

: The manifold gas pressure to be:

3.5” w.c. (±.3) for natural gas.

10.0” w.c. (±.5) for LP gas.

8. To adjust the outlet/manifold pressure, insert a small

slotted screwdriver into the opening at the top of the

valve (see Figure 41).

FURNACE ADJUSTMENTS

Fu

rn

ac

e

Ad

ju

stm

en

ts

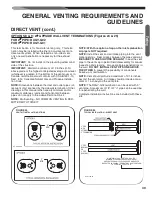

FIGURE 41

SERVO CONTROLLED GAS VALVE PRESSURE ADJUSTMENT

NOTE:

The adjust-

ment wheel will not

stop rotating when

it hits the maximum

or minimum posi-

tion. Instead, it will

continue to rotate to

the opposite adjust-

ment. Use the let-

ters on the wheel

as a guide.

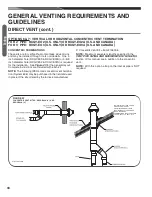

FIGURE 39

OUTLET / MANIFOLD TAP

ST-A1194-88-00

ST-A1194-88-00

ST-A1194-89-00

SUPPLY PRESSURE TAP

OFF/ON SWITCH

LP JUMPER WELL

(INSERT JUMPER HERE)

ADJUSTMENT WELL

ST-A1194-89-00

FIGURE 40

Содержание 97MDV060 Series

Страница 91: ...91 TIMING DIAGRAM TABLE 17 TIMING DIAGRAM FOR NON CALIBRATION GAS HEAT SEQUENCE Timing Diagram...

Страница 98: ...98 Diagnostics TABLE 19 continued R97V FAULT CODES WITH DESCRIPTIONS AND SOLUTIONS...

Страница 108: ...108 FIGURE 65 MODULATING ECM FURNACE WIRING DIAGRAM Troubleshooting CM 0716...