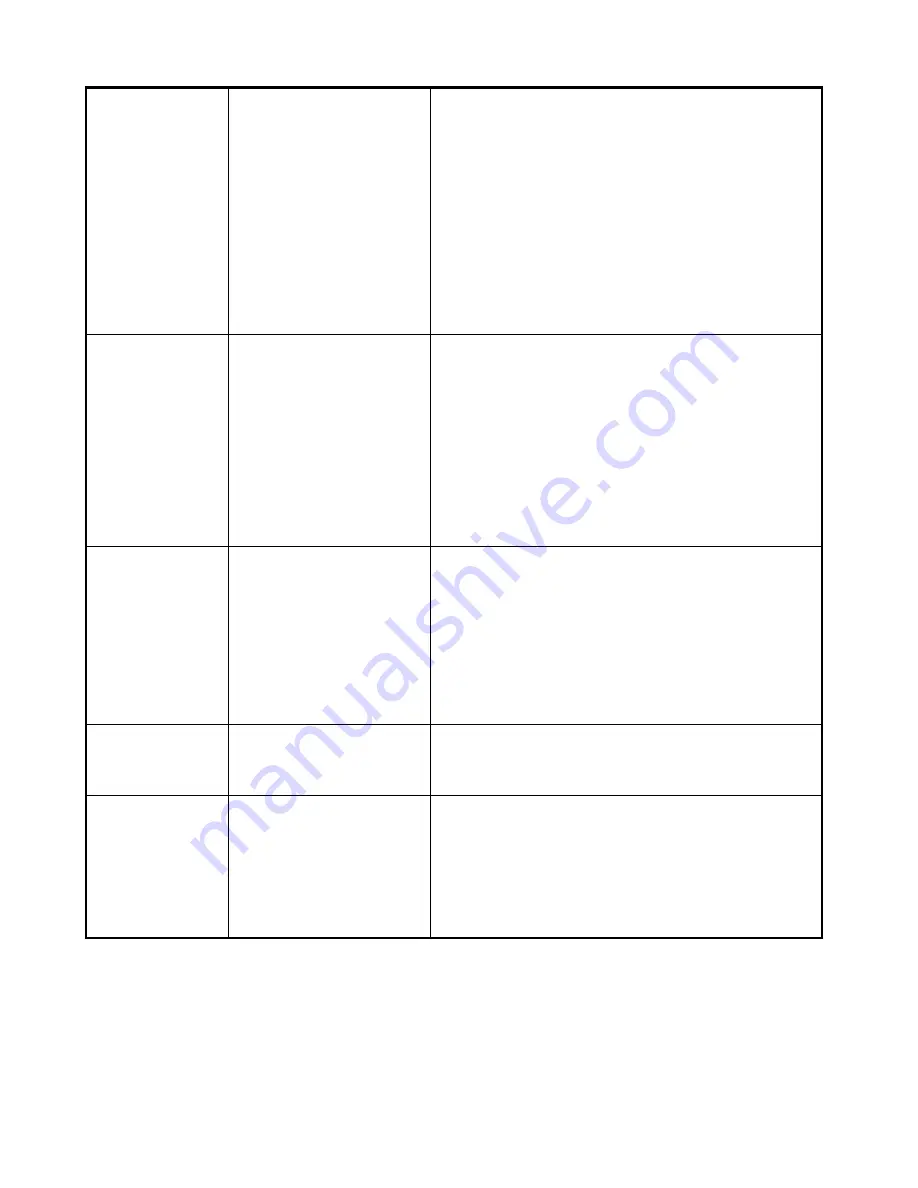

11

Saw operates

erratically

Leak in system.

Saw parts sticking or binding.

Dirt or contaminants in saw

parts.

Tighten fittings. Inspect all hoses for leaks as described in

Section 3.1.1. REPLACE A LEAKING HOSE

IMMEDIATELY. NEVER TRY TO REPAIR IT.

Check for dirt or gummy deposits. Clean parts.

Check for worn or damaged parts and replace as required.

Be sure flanges are clean and straight so blade will run true on

sides. See Chapter 4 for proper blade mounting procedure.

Disassemble saw and clean parts.

Saw operates slowly.

Insufficient flow.

Hydraulic fluid level low.

Hydraulic fluid viscosity too

heavy.

Saw parts loose.

Saw parts worn or damaged.

Refer to power source operator’s manual for proper

adjustment of flow.

Check fluid level. Fill to full mark. Check system for leaks.

Use fluid viscosity recommended. See Section 2.5.

Tighten component hardware.

Disassemble saw and replace worn or damaged parts.

Saw feels hot.

Power source heat exchanger

malfunctioning

Hydraulic fluid level low.

Hydraulic fluid dirty.

Excessive flow

Refer to power source operator’s manual.

Check fluid level. Fill to full mark. Check system for leaks.

Drain reservoir, flush and fill with clean fluid. Change filter.

Refer to power source operator’s manual for proper

adjustment of flow

Saw leaks hydraulic

fluid.

Saw parts loose.

Saw parts worn or damaged.

Tighten component hardware.

Disassemble saw and replace worn or damaged parts.

Saw control valve

sticks or works hard.

Check for dirt or gummy

deposits.

Misalignment or binding of

control linkage.

Valve parts damaged.

Clean parts.

Correct alignment, lubricate linkage joints, and replace

damaged parts.

Disassemble valve and replace damaged parts.

Содержание TS14

Страница 16: ...14 Figure 6 1 TS14 Trenchsaw Assembly...