I-OH (01-20) PN120390R7

33

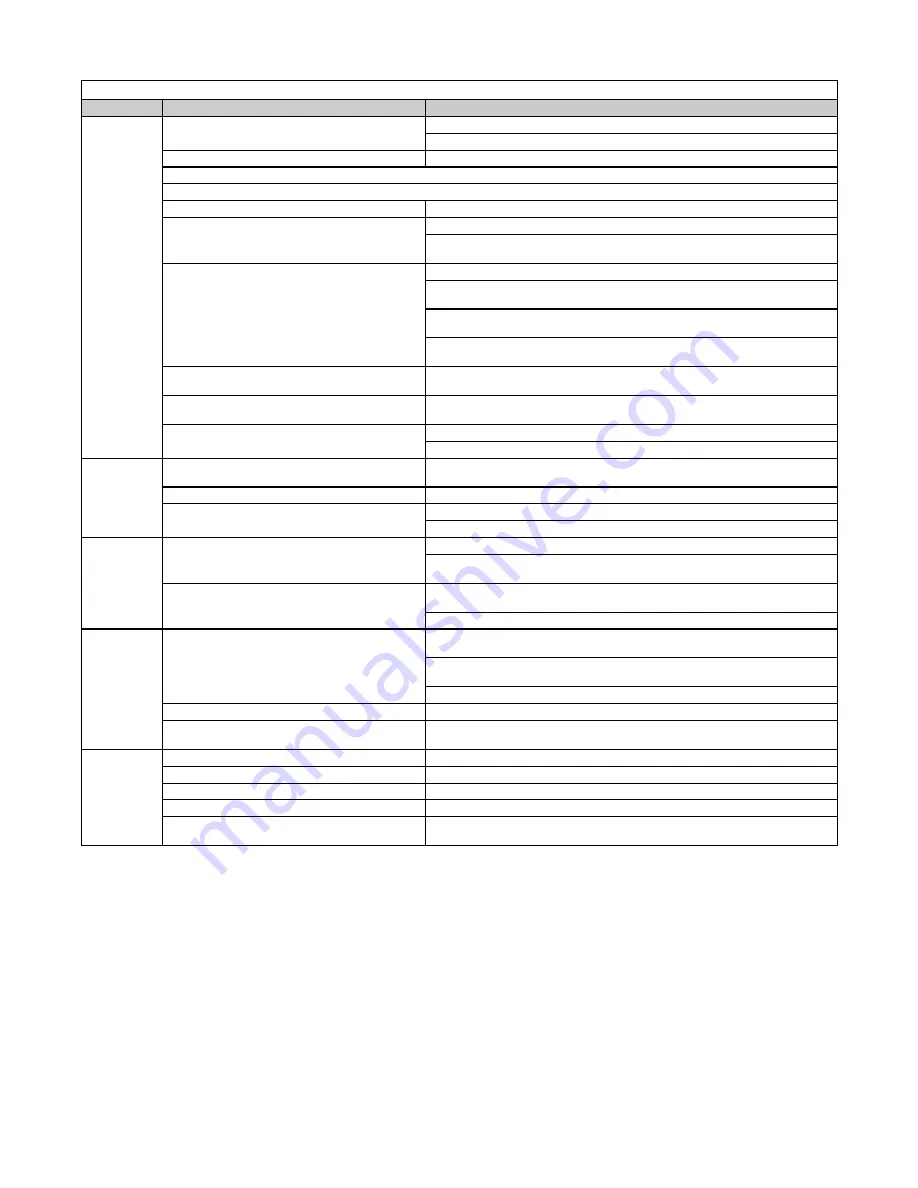

Table 14. Oil Burner Troubleshooting

Symptom

Probable Cause

Remedy

Burner motor

operates and

delivers oil

but there is

no flame

1. No spark

Check transformer, insulators, and electrodes

Transformer/ignition problems may be due to following causes:

a) Excessive gap on ignition electrodes

Ensure that gap is 1/8 inch

b) High ambient temperatures

c) High humidity

d) Carbon residue on the porcelain bushings Clean porcelain bushings

e) Low input line voltage

Measure voltage between transformer/primary lead and neutral connection

NOTE: The secondary terminals of a good transformer deliver 5000V

arc to ground for a total of 10,000V between the terminals.

f) Arcing between ignition electrodes and

transformer springs

Ensure that ignition electrodes and transformer springs have good contact

Measure arc with transformer tester or use well-insulated screwdriver to

draw arc across two springs; ensure that arc is at least 3/4 inch long

Check each secondary output terminal by drawing strong arc between

spring and base

If arc is erratic, weak, or unbalanced between two terminals, replace

transformer

g) Carbon residue, moisture, crazing, or pin

holes on insulators

Clean any carbon residue and replace any insulators that are questionable

h) Improper positioning of nozzle in relation

to radius of endcone

Check and correct nozzle position as necessary

i) Carbon residue on electrode parts

Clean any carbon residue

Replace electrodes when tips become worn or eroded

Burner starts

but flame

blows away

from nozzle

1. Excessive combustion air

Adjust air band and air shutter in accordance with

section

2. Excessive draft

Adjust draft regulator for 0.01 IN WC overfire draft

3. Poor atomization of oil

Adjust fuel feed pressure

Replace oil nozzle as necessary

Poor light

off and shut

down

1. Air pocket between pressure shutdown valve

and nozzle

Tighten unused intake port plug in fuel pump

Run burner, stopping and starting occasionally until pulsation, smoke, and

after-flame disappear

2. Insufficient draft over fire

Check venting for excessive length, insufficient pitch upward to chimney,

too many elbows, obstructed chimney, or too small chimney

Check for too high combustion air setting

Noise

1. Noisy motor

Check for alignment of shaft with coupling and tighten or slightly loosen

motor-to-burner-housing bolts in alternate sequence

Check for loose blower wheel, excessive radial shaft play, and loose start

switch parts

Check if thermocouple is laying on blower wheel

2. Clogged strainer

Remove and clean strainer

3. Burner vibrations transmitted through rigid

electrical conduit or oil lines

Ensure that tubing or conduit is not fastened to studs or beams so securely

that vibration is transmitted to floor or roof

Oil Odors

1. Oil leak(s)

Check fittings and valve seals

2. Poor burner shutoff

Check fuel shutoff valve and time delay relay

3. Smoky flame

Check nozzle spray, air gap, and air shutter setting

4. Oil carbonization on burner endcone

Check nozzle location relative to inside radius of endcone

5. Downdraft causing smoke to enter building

through barometric draft regulator

Increase draft by extending chimney height or by adding ventilating cap or

draft inducer

—Continued