8/25

3.3.1 Flues for power vented installations

(Type B appliances)

If the air heater is to be installed as a type B

appliance, air for combustion will be taken from

within the space where the heater is installed.

Ensure that an adequate air supply for combustion

and ventilation is provided within the building in

accordance with the regulations & rules in force.

Table 5 shows flue pipe sizes and maximum pipe

lengths. The minimum flue length is 0.5 metres.

Table 5 Flue pipe diameters & maximum lengths

12

35->145

Heater socket &

pipe dia

Equivalent length

m

of 45° elbow

1.5

80

9

20, 30

100

130

LCSA-4

mm

m

Equivalent length

of 90° elbow

Maximum straight

length

m

0.75

Single wall flue pipes are required. All joints must

be sealed to prevent products of combustion from

leaking into the building. An approved flue terminal

is required.

If the flue passes through a combustible element of

the building it must be enclosed by a sleeve of non-

combustible material and separated from the sleeve

by at least a 25 mm air break. The temperature of

any combustible material near to the flue must not

exceed 65°C when the heater is in operation. The

flue must be at least 50 mm away from any

combustible material.

Single wall flue pipe exposed to cold air or run

through unheated areas must be insulated. Where

condensation is unavoidable, provision must be

made for the condensation to flow freely to a point

to which it can be released, i.e. a drain or gully. The

condensation drain from the flue must be

constructed from non-corrodible material not less

than 20 mm diameter. Copper or copper based

alloys must not be used for condensation drains.

3.3.2 Combustion air inlet pipe & flue pipe for

balanced flue installation (Type C appliances)

Balanced flue air heaters are designed to be fitted

with a combustion air inlet pipe that obtains outdoor

air and a flue pipe that exhausts flue products to

outdoors.

Air heaters if fitted with a power venter permitting

either a vertical or horizontal combustion air

inlet/flue pipe system.

The heaters must be

installed with a concentric vertical or horizontal

flue/combustion air inlet. The heaters are only

approved for use when installed with the

appropriate approved concentric vent terminal.

See table 6.

Both the flue and combustion air pipes must be sealed.

Use gasket sealed seamless aluminium pipe or

equivalent.

The flue pipe must include a re-sealable test port to

allow good average sampling of the flue gas mixture

for testing, the port must be at least 450 mm away

from the air heater flue connection socket.

Follow any flue pipe manufacturers’ installation

instructions for making joints, including connections to

the air heater, for passing through a building element

and for support requirements. If more than one air

heater is being installed in the same place each heater

must have a separate flue system.

Where condensation is unavoidable, provision must

be made for the condensation to flow freely to a

point to which it can be released, i.e. a drain or

gully. The condensation drain from the flue must be

constructed from non-corrodible material not less

than 20 mm diameter. Copper or copper based

alloys must not be used for condensation drains.

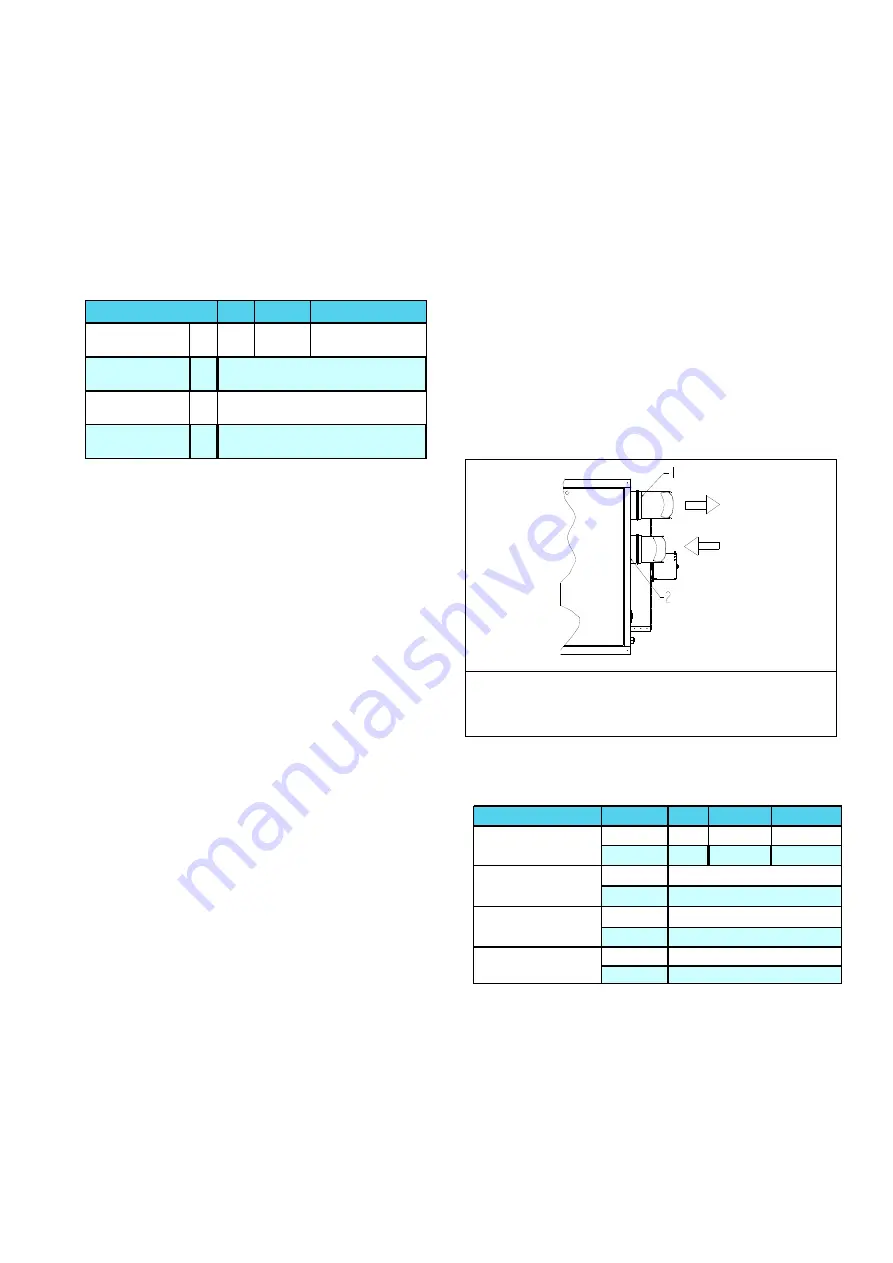

Figure 2b :

Combustion air and flue pipe sockets,

Type C

Legend :

1 Flue products flue outlet socket for flue pipe

2 Combustion air inlet opening

Table 6

Combustion air inlet & flue pipe requirements

LCSA-4

12

35 -> 145

Flue pipe

80

130

Inlet pipe

80

130

Flue pipe

Inlet pipe

Flue pipe

Inlet pipe

Flue pipe

Inlet pipe

Max. straight

length

m

20, 30

100

100

9

9

Heater socket

& pipe dia

mm

Concentric vertical vent or wall terminal : Mugro/Burfix dia 130

Concentric horizontal vent or roof terminal : Mugro/Burfix dia 130

Equivalent length

of 45° elbow

Equivalent length

of 90° elbow

m

m

1,5

1,5

0,75

0,75