- 12 -

5. Operating Instructions

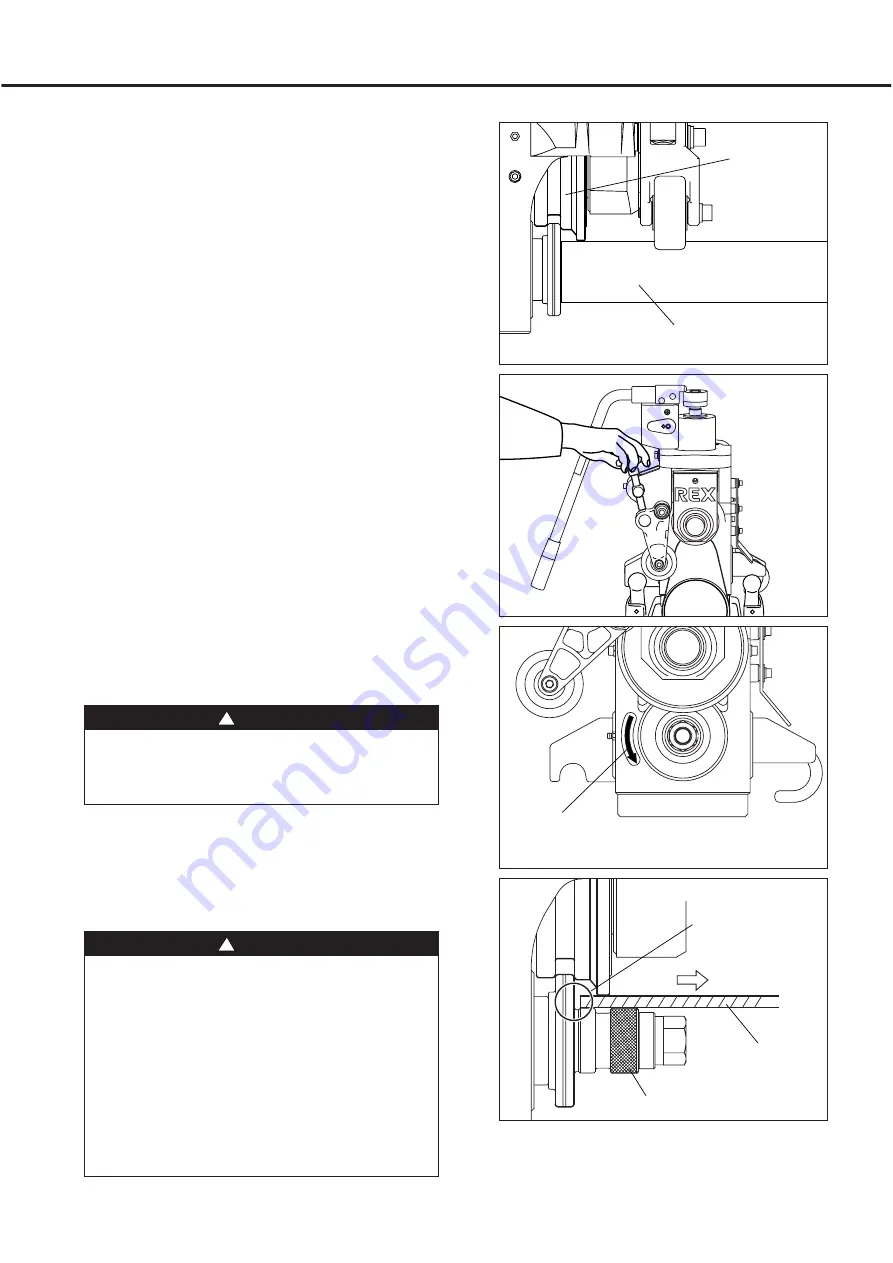

1) Turn the hydraulic pump valve to the ON

position, and pull the pump handle up quickly

and firmly to engage the pipe lightly with the

upper roller and then raise the pump again.

2) Turn the push knob on the guide roller to

lightly engage the guide roller with the pipe.

In this position, tighten the knob a further half-

turn to push the guide roller against the pipe.

(Fig. 22)

The amount you tighten depends on the pipe.

Tighten lightly for thin pipes; more for thick or

hard pipes.

Ascertain the most suitable amount you should

tighten according to the pipe's size and

material. If you tighten too much, the end of

the pipe will flare; if not tightened enough, the

pipe may fall out when working on it.

3) If the threading machine has a switch for

changing directions, use in the forward

(normal) direction position for cutting threads.

(Fig. 23)

3. Grooving

4) Turn the threading machine on to start the

pipe rotating.

Allow the pipe to rotate several times to

ensure that the pipe does not slip away from

the lower roller flange.

㧍

CAUTION

㨯

If you use the machine in the opposite

direction to threading (reverse), the pipe

may fall out, which can be very

㧍

WARNING

㨯

Should the pipe slip off the lower roller,

turn the threading machine OFF

immediately to stop it rotating. If the pipe

slips out while still rotating, the pipe will

become detached from the lower roller

and could fall out, which is very dangerous.

(Fig. 24)

Loosen the hydraulic valve and reset the

pipe. If the pipe slips out, shift the pipe a

little more.

Fig. 22

Fig. 24

Fig. 23

Fig. 21

Correct

direction

Upper Roller

Pipe

Lower roller

Pipe

If the pipe slips out,

immediately turn

the switch OFF.

Pipe slipping out