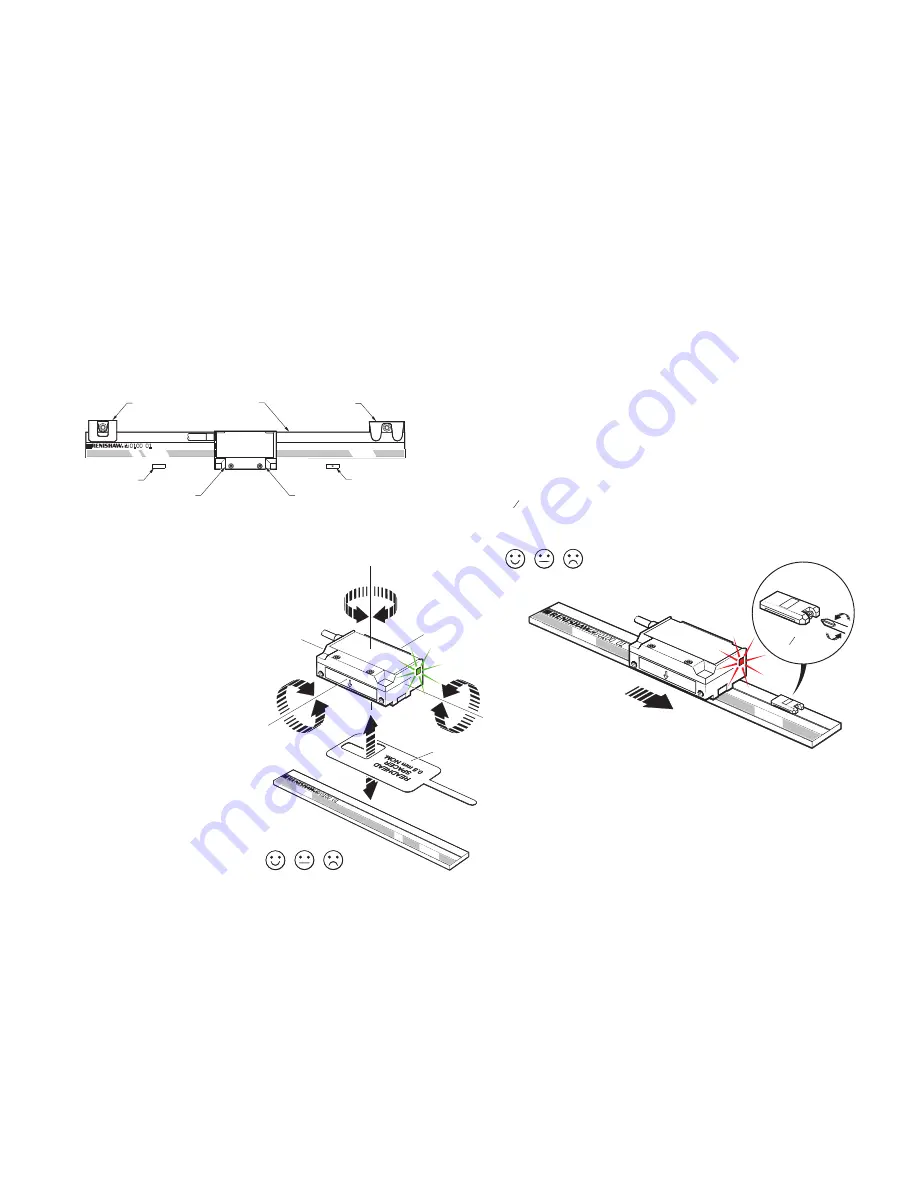

Yaw

0° ±1°

Pitch

0° ±1°

Roll

0° ±1°

Rideheight

0.8 ±0.15 mm

Blue spacer

Reference mark set-up

To ensure uni-directional repeatability, the reference mark requires phasing with the scale in

the direction of normal datuming operation.

A reference pulse is output in both directions, but repeatability is guaranteed only in the

phased direction.

Ensure readhead is set-up correctly with a Green LED indication over the full length of travel and

that the reference mark actuator is fitted correctly.

NOTE:

It is recommended that a datum procedure is performed as part of any power-up sequence

to ensure the correct datum position is recorded.

NOTE:

Reference mark output is synchronised with the incremental channels, giving unit of resolution

pulse width. For further details see ‘Output specifications’.

Phasing procedure

The readhead must be moved over the reference mark in the direction to be used for the datuming

operation. The reference mark is phased correctly when the set-up LED flashes Red for 0.25 seconds.

If it flashes Orange or goes blank, the reference mark adjuster screw should be turned anti-clockwise

by

1

8

turn and the procedure repeated until a Red flash is obtained.

1

8

turn

Red Orange Blank

Readhead set-up LED flash during

reference mark traverse only

RGH40 RGS40-G

installation guide

8

Adhesive P and Q limit magnets (A9531-0251) should be mounted using RGG-2 epoxy (A-9531-0342).

Ensure epoxy is thoroughly mixed prior to use. Allow 24 hours at 20

°C for full cure.

Optional bolted limit magnets available, see RGH40 installation drawing for details.

Readhead mounting and alignment

Mounting brackets

The bracket must have a flat mounting surface, enable conformance

to the installation tolerances, allow adjustment to the rideheight of

the readhead, and be sufficiently stiff to prevent deflection or

vibration of the readhead during operation.

For easier installation, adjust the roll and yaw of the bracket

with respect to the axis of readhead travel before the

RGH40 is attached. This can be done with a

clock gauge and a precision square.

Readhead set-up

To set nominal rideheight, position readhead spacer

with ‘L’ shaped aperature under the optical centre of

the readhead to allow normal LED function during

set-up procedure. Ensure that the scale, readhead

optical window and mounting face are clean and

free from obstructions.

NOTE:

Ensure readhead fixing screws are tightened

to 0.5 Nm – 0.7 Nm.

For reliable operation, the set-up LED should be GREEN

when readhead is moved along the full axis of travel.

An external set-up signal, X, is also available

on RGH40 readheads for use where the

LED is not visible.

See ‘Output specifications’ for details.

Datum clamp

Scale

Mounting clip

P limit magnet

P limit sensor position

Q limit sensor position

Q limit magnet

Reference mark actuator installation

Refer to RGH40 readhead installation drawing and RGS40-G scale installation drawings for actuator positioning.

Reference mark actuator (A-9531-0250) should be mounted using RGG-2 epoxy (A-9531-0342). Ensure epoxy is

thoroughly mixed prior to use. Allow 24 hours at 20

°C for full cure.

Limit switch installation

Screw mounted or adhesive mounted limit switch actuators are available. Refer to RGH40 readhead installation

drawing and RGS40-G scale installation drawings for actuator positioning.

Green Orange Red

Readhead set-up LED status

Limit switch

Limit switch detection is entirely independent of other readhead functions - the signal is only output

when the readhead is positioned over the limit switch actuator.