Air bleeding valves

The unit has manual air bleeding

valves. The unit can be vented

separately after the system

has been filled. Automatic air

bleeder must also be installed at

the highest point in the collective

lines.

Glycol suitable valves are

necessary when using medium

that contain glycol.

!

CAUTION

A minimum medium volume in

the system may mot fall below

3.5l/kW per power stage.

!

CAUTION

Improperly installed or missing

dirt traps can cause fouling of

the plate heat exchanger.

!

CAUTION

Fill and drain connection

A connection should be provided

in an area safe from frost for the

draining of the pipe lines (especial-

ly if water is used as a medium).

Applicable local disposal regula-

tions must be observed if glycol is

used.

Dirt trap

A self cleaning dirt trap must be

installed on the intake side of the

unit. The mesh size should not be

less than 10 mesh/cm². Shutoff

valves should be installed on both

sides of the dirt trap.

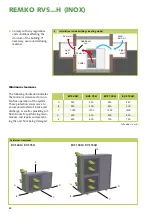

External medium storage tank

If, for example, the necessary ca-

pacity of the appliance indoor unit

is significantly less than the cooling

capacity of the chiller, an increase

in the medium content is recom-

mended. Either the medium lines

can be oversized or an additional

storage tank installed.

A storage tank should, as a rule,

be provided if the minimum me-

dium volume of the system is not

reached.

Shut-off valves

As a rule, in such systems, shut-

off valves (ball valve) with open

passages should be used. For the

purpose of servicing, medium

intake and medium outlet must be

equipped with shut-off valves (if

necessary safety valves).

Condensate draining and

ensured discharge

Condensate connection

If the temperature falls below the

dew point, condensation will form

on the finned condenser during

heating operation

.

A condensate drip pan should be

installed on the underside of the

unit to drain any condensate.

■

The condensate drain pipe to

be installed on-site must be in-

stalled with a in cline of at least

2 % for good drainage.

If necessary, fit vapour density

insulation.

■

When operating the system at

outdoor temperatures below

4 °C, care must be taken that

the condensate line is frost

protected. The lower part of the

housing and condensate pan

are to be kept frost free in order

to ensure permanent drainage

of the condensate.

If necessary, fit supplementary

pipe heating.

■

After completed installation,

check that the condensate

drainage is unobstructed and

ensure that the line is leak tight.

Condensate drain

25

Содержание RVS 100H INOX

Страница 2: ......