18

11. Now tighten the bolts using 2 hexagonal wrenches

that have a large enough opening.

12. Use a second wrench to apply counterpressure

when tightening.

13. Insulate the installed refrigerant lines including the

connector against heat.

Only use insulation hoses sealed against diffusion

that are suitable for this temperature range.

14. Connect the condensation and control lines.

If you also need a condensation pump, install it be-

forehand.

15. If it is not possible to run the condensation line

through the same guideway, make sure that the

condensation can drain freely at all times.

16. Lay the refrigerant lines from the indoor unit to the

outdoor part.

Make sure that they are adequately secured. Take

steps, if necessary, to ensure oil recirculation!

17. Place the control line in the same line guideway.

18. Remove the protective caps supplied and the swivel

nut caps of the shut-off valves and use these for

continued assembly.

19. Before you flare the refrigerant lines, ensure that

there is a swivel nut on the hose.

Only use the factory-installed swivel nuts.

20. Connect the refrigerant lines to the outdoor part as

described above.

G

If the length of the connection line is longer than 5

m, refrigerant must be added to the system during

initial operation.

See the section Adding Refrigerant.

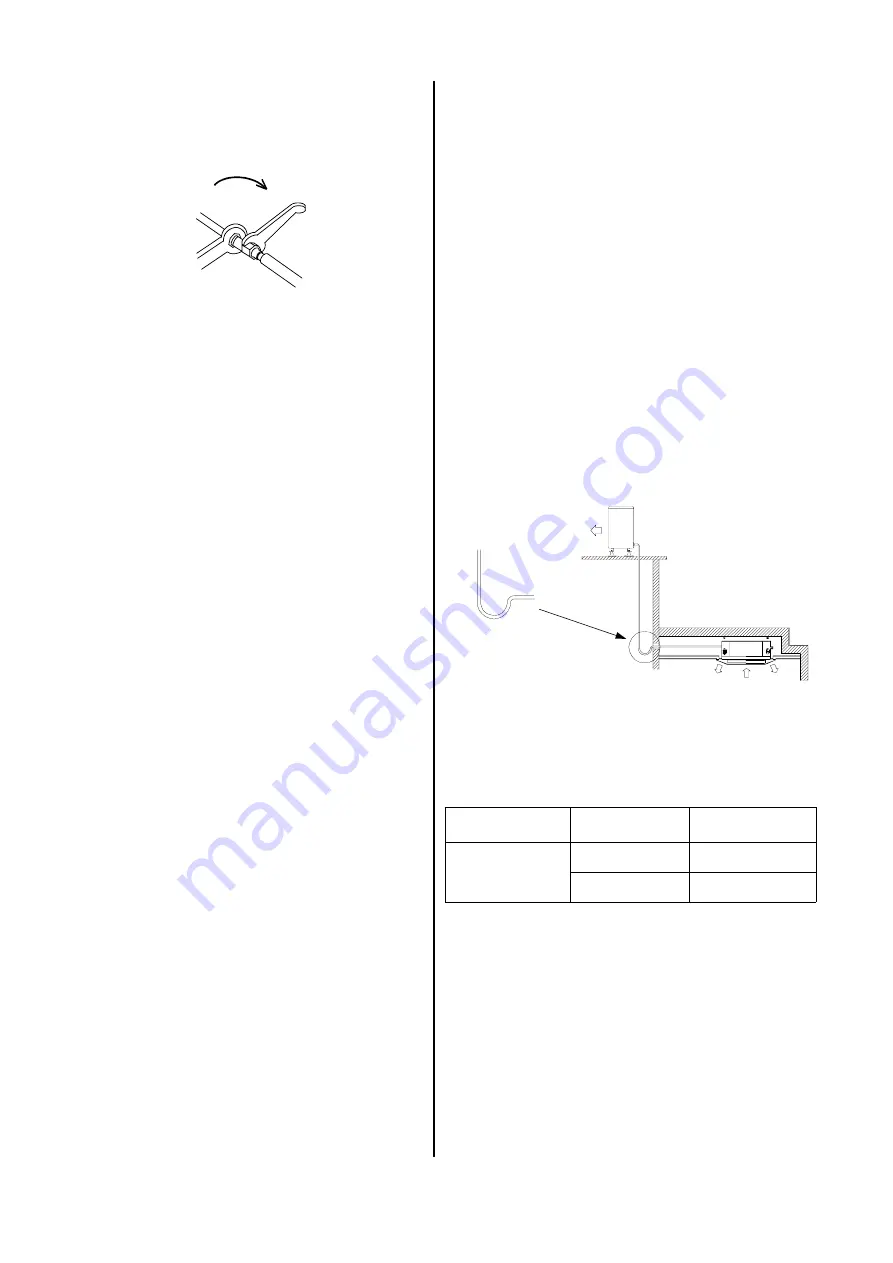

Oil recirculation

If the outdoor part is set up at a higher level than the in-

door unit, appropriate steps must be taken for oil recir-

culation.

This is usually accomplished by creating an oil elevation

arc that is installed every 2.5 meters of line going up.

Impermeability test

Once all connections have been made, the manometer

station is connected to the corresponding valve connec-

tions as described below:

blue = large valve = suction pressure,

After the connection has been made, an impermeability

test is conducted using dry nitrogen.

The connections that have been established are

sprayed with a leak locator spray to test for imperme-

ability. If bubbles appear, the connection was not made

properly. Tighten the bolts more firmly or, if necessary,

create a new flare.

After the impermeability test has been successfully con-

ducted, any excess pressure is removed from the refrig-

erant lines and the vacuum pump put into operation to

create a vacuum in the lines.

We recommend using a two-speed vacuum pump with

an absolute final partial pressure of at least 0.01 mbar

at a pump capacity of a min. of 1.5 m³/h.

Procedure:

1. Remove the vacuum pump and connect the filling

cylinder or the refrigerant container.

2. Place the open cylinder/container on a scale and

calibrate the scale to zero.

3. Create a vacuum in the hose at the height of the ma-

nometer distribution pipe.

4. Determine the required amount based on the infor-

mation in the table above and open the suction pres-

sure side of the manometer to begin the filling proc-

ess.

5. Close the manometer valve when the appropriate

amount has been added.

Length of the line

Diameter of the

injection line

Additional quantity

per m

5 m up to and

including a max.

of 15 m

9.52 mm Ø

/

3

/

8

‘‘

18 g for RKS

9.52 mm Ø

/

3

/

8

‘‘

30 g for RKM

Adding refrigerant

The additional refrigerant amount required is based on

the length (5 m and higher) and the diameter of the

pressure line.

Counterpressure

open-end wrench 1

Counterpressure

open-end wrench 2

G

A vacuum with a minimum of 0.05 mbar must be

created!

How long it takes to create the vacuum is based on the

hose line volume of the indoor unit and the length of the

refrigerant lines. However, this process takes a mini-

mum of 30 minutes.

Once foreign gases and moisture have been completely

removed from the system, the manometer station

valves are closed and the valves of the outdoor part are

opened.

Radius

min. 50 mm

Oil elevation arc in the

suction line to the outdoor

part 1x for every 2.5 m

Outdoor part

Indoor unit

Содержание RKV 13 C

Страница 2: ......