18

Remeha

Gas 3002 ECO

the control will convert the vol ta ge into the required flow

temperature, higher than the measured flow temperature.

At the user level, it is possible to set the maximum

operating temperature. The set point will be limited to this

level, irrespective of whether the analog input calls for a

higher temperature.

B.2 External control

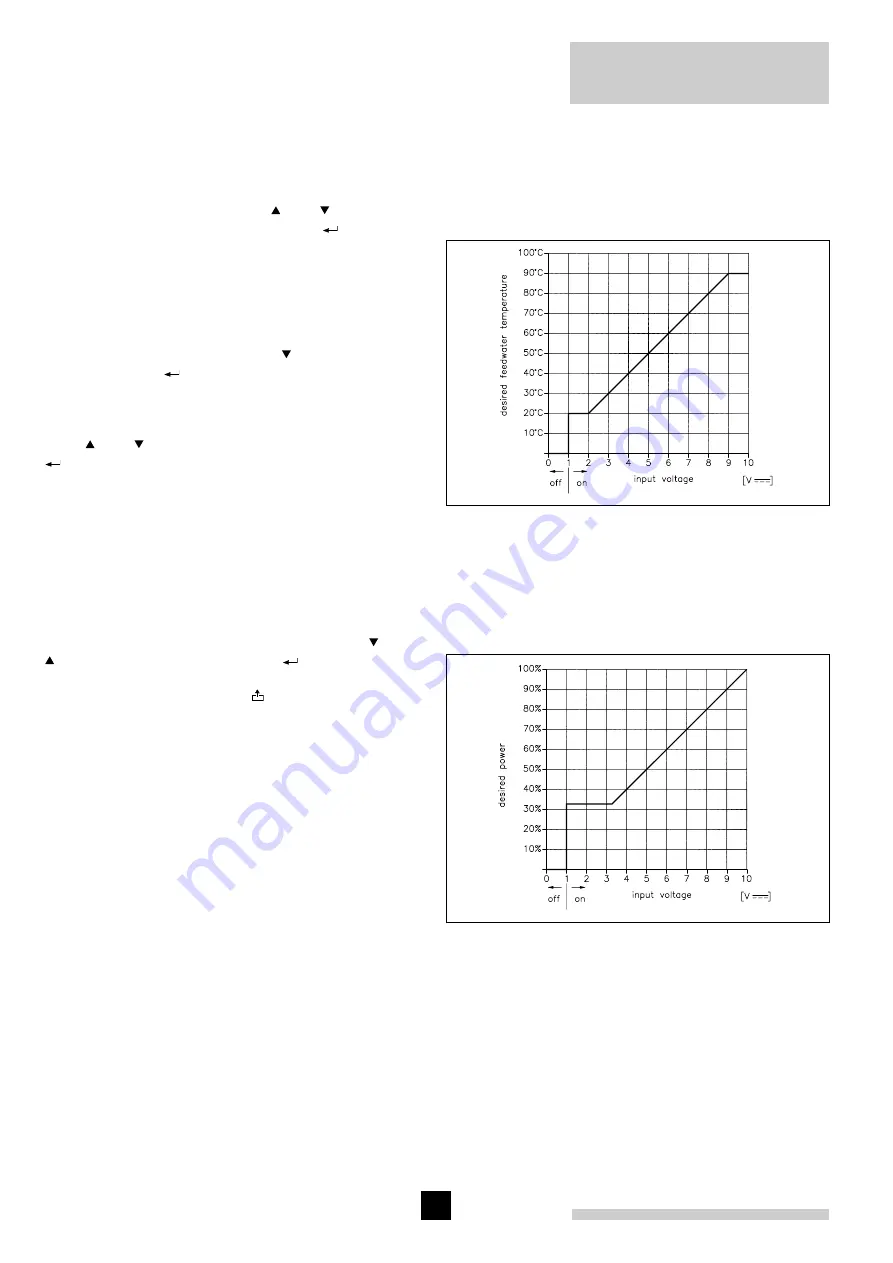

The required power is 0% at 0V and 100% at 10V

(see figure 13). As soon as the voltage exceeds 1V,

the boiler will switch on. As soon as the voltage falls

below 0,5V the boiler will switch off. The maximum

operating temperature can be set at the user level.

C. Computer

C.1 Internal control

The boiler can also be controlled using a computer,

modem or GBS system. The switch-on command and

the required flow temperature is passed on to the

boiler via the RS 232 connection. All values, settings,

etc. can now also be read via the RS 232 connection.

C.2 External control

In this structure, the switch-on and switch-off commands

and the required power are transmitted via the RS 232

connection. Here too, all measurement values and set

tings can be passed on through this connection.

7.3.3 Service level

To prevent unwanted settings by non-experts the service

level can only be accessed after entering a security code.

The security code for this level is 0012.

After entering this code using the ' ' and ' ' buttons in

menu 5 and confirming it by pressing the '

' button, the

service level is accessed.

Now, a selection can be made from 4 options:

1) Service settings

2) Service test

3) History data

4) Service level

II

(factory level).

Select the desired option using the ' ' button and confirm

it by pressing the '

' button.

To 1) Service settings

Various settings can now be made (select desired option

using ' ' and ' ' button and confirm it by pressing the

'

' button.

Option 1: Input selection

Offers the posibility of an internal PI-regulation, by which

the boiler regulates its output based on flow temperature

and the possibility of an external PI-regulation, by which

the boiler output is regulated by means of an external

regulation.

The selection of the options can be obtained by placing

the cursor onto the chosen line by means of the ' ' and

' ' buttons and by pushing next the '

' button. The

choice is confirmed by the two arrow heads which appear

on the selected line. Using the ' ' key, you switch to the

next screen, where it is possible to select the method

according to which the required temperature or required

power can be passed on to the boiler control. There are

three possibilities:

A. Contacts

A.1 Internal control

Via a potential-free contact, the boiler receives a heat

demand command. At the user level, the required flow

temperature can be set. The boiler now will modulate

on base of this temperature.

A.2 External control

Via two potential-free contacts, the boiler can be

switched to minimum or maxi mum power. At the user

level, the maxi mum flow temperature can be set.

B. Analog

B.1 Internal control

The required flow temperature is passed on to the

boiler control via a 0-10V analog signal. As standard,

this signal is set to a temperature of 0°C at 0V and

100°C at 10V (see figure 12), but via the two following

screens it is possible to allocate different values to

the tarting and finishing points, depen ding on the type

of control used. At 0V, a temperature of between -50°C

and +50°C can be selected, and at 10V, a temperature

of b50°C and +300°C. Via a linear line,

Fig. 13 External boiler control by analog (0-10 V) signal.

Fig. 12 Internal boiler control by analog (0-10 Volt) signal.