Controller

12

—

English

Fillcontrol Auto

—

22.09.2020 - Rev. C

8.1.5

Restarting

CAUTION

Risk of injury due to pump start-up

Hand injuries may occur when the pump starts up if you turn the pump

motor at the impeller using a screwdriver.

•

Switch the pump to a zero-volts state before turning the pump at the

fan wheel with a screwdriver.

ATTENTION

Device damage due to pump start-up

Pump damage may occur when the pump starts up if you turn the pump

motor at the impeller using a screwdriver.

•

Switch the pump to a zero-volts state before turning the pump at the

fan wheel with a screwdriver.

After an extended standstill time (the device is de-energised or in Stop mode),

the "PU" pump may jam.

•

Use a screwdriver to rotate the pump at the fan wheel of the pump motor

before restarting.

Note!

A jamming of the "PU" pump is prevented during automatic operation

thanks to forced starting action (after 24 hours).

9

Controller

9.1

Operator panel

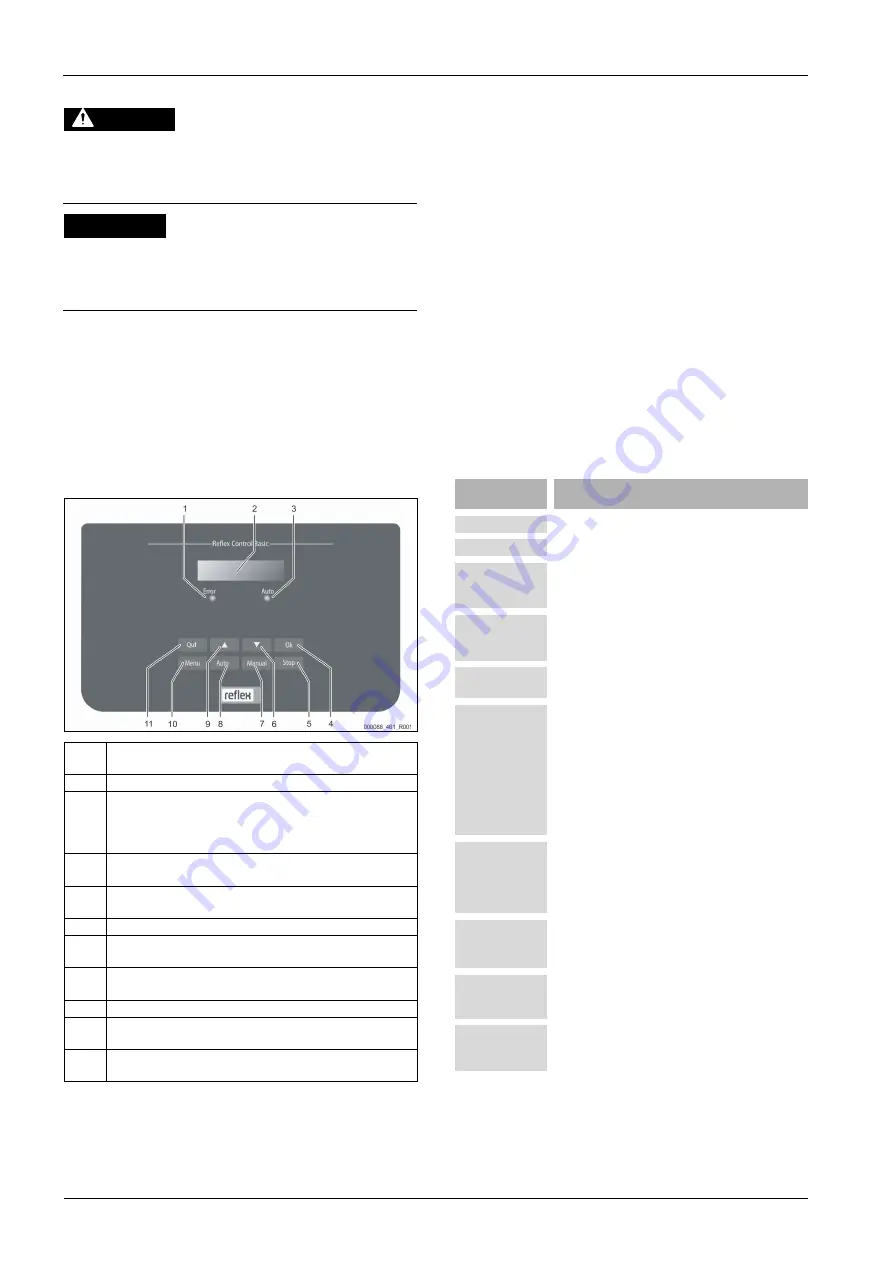

1

Error LED

•

The Error LED illuminates in the event of a fault

2

Display

3

Auto LED

•

The Auto LED illuminates green in Automatic mode

•

The Auto LED flashes green in Manual mode

•

The Auto LED is not illuminated when the system is stopped

4

OK

•

Confirm actions

5

Stop

•

For commissioning and entry of new values in the controller

6

"Back" to the previous menu

7

Manual

•

For tests and maintenance tasks

8

Auto

•

For continuous operation

9

"Forward" to the next menu

10

Menu

•

Call up the Customer menu

11

Quit

•

Acknowledge messages

Selecting and changing parameters

1.

Use "OK" (5) to select the parameter.

2.

Use the "

▼

" (7) or "

▲

" (9) arrow keys to change the parameter.

3.

Use "OK" (5) to confirm the parameter.

4.

Use the "

▼

" (7) or "

▲

" (9) arrow keys to switch to a different menu

option.

5.

Use "Quit" (11) to switch to a different menu level.

9.2

Configuring settings in the controller

System-specific values can be corrected via the customer menu. In the course of

initial commissioning, the factory settings must first be adjusted for the system-

specific conditions.

Note!

For a description of the operation, see chapter 9.1 "Operator panel" on

page 12 .

All grey marked menu items must be reviewed during commissioning.

Press "Manual" to switch to manual operation.

Press "Menu" to display the first main menu option "Customer menu".

To navigate and set the values:

•

Use the "

▼▲

" arrow keys to navigate and set the values in the selected

main menu.

•

Press "OK" to open the next sub-menu.

•

Press "OK" to confirm the changed setting in the sub-menu.

Indication on the

display

Meaning

Customer menu

Switch to the next main menu option.

Language

Standard software in various languages.

Time:

Adjust the "Hour", "Minute", and "Second" display when

each begins to flash.

This time is used for entries in the fault memory.

Date:

Adjust the "Day", "Month", and "Year" display when each

begins to flash.

This date is used for entries in the fault memory.

Fillcontrol /

Magcontrol

Select between the make-up variants "Levelcontrol" and

"Magcontrol".

Min.op.pressure

01.8 bar

The system displays the "Minimum working pressure"

message when you have set the "Magcontrol" make-up

variant. Enter the value for the minimum operating

pressure.

Note!

Calculation of minimum operating pressure, see

chapter 7.2 "Determining the P

operating pressure for the controller" on page 9

.

Safety valve

pressure

The system displays the "Safety valve pressure" message

when you have set the "Magcontrol" make-up variant.

Specify the tripping pressure of the applicable safety

valve for the device protection. This is usually the safety

valve at the system heat generator.

Make-up

Switch to the "Make-up" sub-menu.

•

Press "OK" to open the menu.

•

Use the "

▼▲

" buttons to open the sub-menu.

Max. make-up time

010 min.

Pre-selected time for a make-up cycle. Upon expiry of

this set time, the system interrupts the make-up and

returns the "Make-up time" fault message.

Max. make-up

cycles

003 / 2 h

If the set number of make-up cycles is exceeded within

two hours, the system interrupts the make-up and

returns the "Make-up cycles" fault message.