Introduction

System Protection

14

System Protection

Red Jacket recommends a complete system built around the pump to ensure safety, reliability, stability, and

performance. If the entire system is calculated and built according to accepted specifications, the installation will

operate for many years without requiring any form of maintenance.

There are two pump characteristics that can be checked if performance deteriorates:

1. Its output - flow rate versus pressure.

2. Its electrical connections and amperage consumed under load.

Potential Problems

Red Jacket submersible LPG pumps are multi-stage centrifugal pumps. The advantage of the multi-stage

technology is maximum performance by a minimum of energy, respectively 2.25 kW (3 hp) for the 21 stage

Premier pump, 2.25 kW (3 hp) for the 17 stage Premier MidFlow pump and 3.75 kW (5 hp) for the 24 stage

Premier HiFlow pump. During operation the pressure increases with approximately 50 kPa (7.25 psi) per stage up

to the maximum design pressure of the pump respectively 1000 kPa (145 psi) for the Premier pump, 880 kPa

(127 psi) for Premier MidFlow pump and 1220 kPa (180 psi) for Premier HiFlow pump.

For all types of Red Jacket submersible LPG pumps the minimum differential pressure can never be below 400

kPa (58 psi). This minimum required differential pressure is to guarantee that during operation all respectively 17,

21 or 24 stages are submerged in the LPG liquid. Another basic rule for a centrifugal pump is that there must be

sufficient liquid available by the inlet of the pump. The pump can only build differential pressure when the first

stage of the pump is completely submerged in the liquid. This so-called NPSH (Net Positive Suction Head) is 127

mm (5 inches) above pump inlet opening for all types Red Jacket submersible LPG pumps.

Cavitation is when the liquid flows with a velocity high enough to reduce the local pressure below vapor pressure

forming small gas-filled bubbles. These gas-filled bubbles exhibit complex dynamics and erosive action on nearby

surfaces.

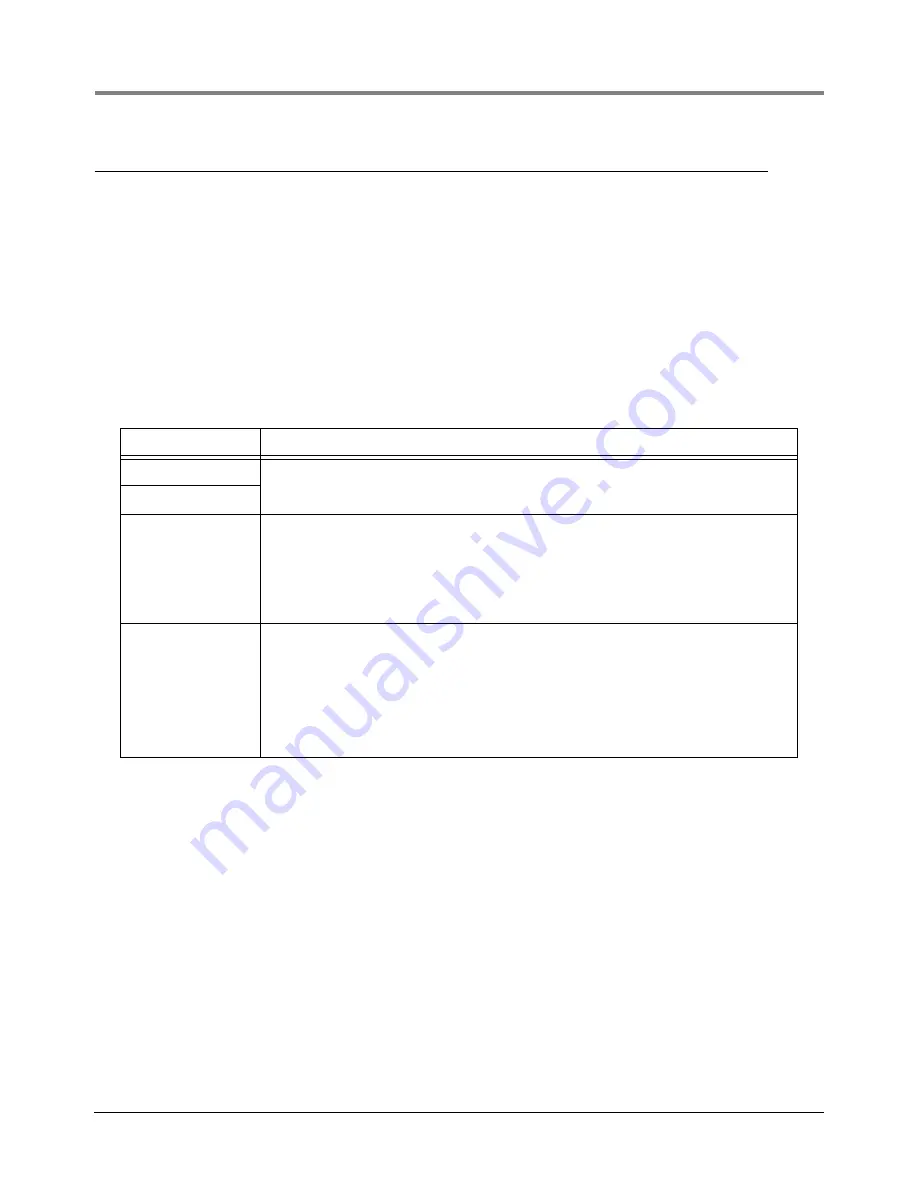

Table 5. Potential Performance Problems

Problem

Solution

Dry run

A control box with low pressure detection can detect both of these performance prob-

lems.

Cavitation

Equalization line in

the manifold is too

small

The Red Jacket LPG pump has an internal by-pass. A certain amount of LPG passes

and cools the motor (self-maintaining principle) and exits the pump at the internal by-

pass. The motor’s heat is transferred to the liquid and is therefore warmer than the liq-

uid in the tank. Also this liquid has a higher vapor pressure than does the liquid in the

tank. The equalization line between the manifold and the tank is to balance both liquid

levels. If this equalization line is too small or even closed, the manifold can be emptied

through the manifold inlet and it can cause a dry run or even cavitation.

Dirt in the tank

Small parts of LPG dust or iron oxide, which can normally be found in LPG, will not

hurt the system. During operation those particles can, however, block the breather

plugs at the inlet of the pump-motor, but when the pump is switched off a small amount

of liquid will be pressurized back in the tank. This amount of liquid will clean the

breather plugs again.

Of course, any form of dirt should be avoided and shortens the expected lifetime of the

pump. It is recommended to install a strainer (100-micron) at the inlet of the storage

tank to avoid dirt entering the tank during deliveries.

Содержание LPG Premier

Страница 1: ...Manual No 051 327 1 Revision N Installation Guide LPG Premier LPG Premier MidFlow LPG Premier HiFlow...

Страница 38: ......

Страница 39: ......

Страница 40: ...For technical support sales or other assistance please visit www veeder com...