Servicing and maintenance

6

BAL_C127-SU_OFFSET_EN_1V0_REC_121-006454770

25 / 32

6

Servicing and maintenance

6.1

General remarks

According to current legislation, the operator of an automatic door system is responsible for its main-

tenance and safety.

Accidents or defects can be avoided if the system operator takes good care of the system.

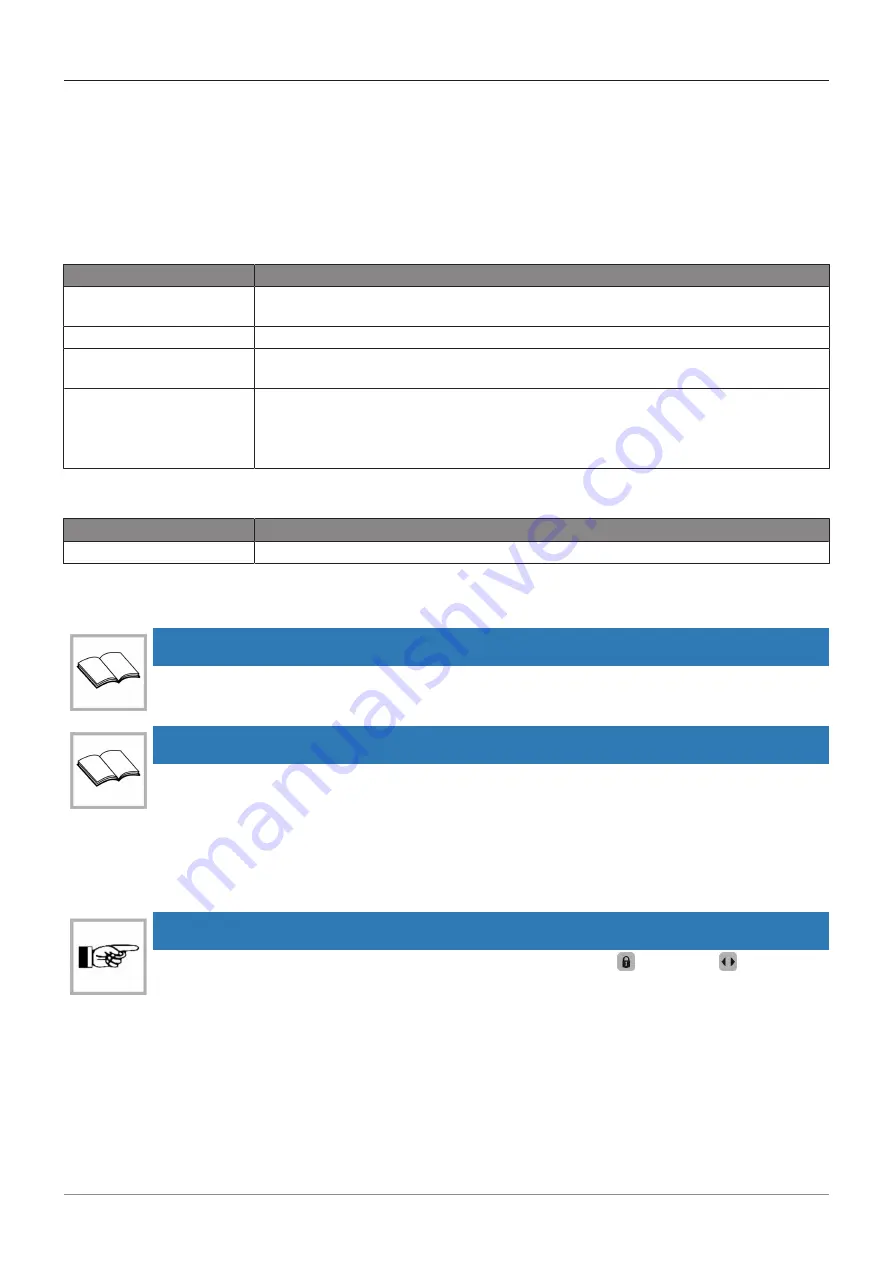

Testing

Type of test

Measure

Visual inspection

Check door leaves, guides, bearings, limiting devices, sensors, and the securing of

crushing and shearing points for damage.

Mechanical inspection

Check fastenings for tight fit.

Safety check (exit and es-

cape routes)

Check sensors, safety devices, and monitoring devices for tight fit and damage.

Function testing

Check functioning of switches, operators, controllers, power or energy storage

devices, and sensors.

Also check the adjustment of the safety devices and the setting of all movement se-

quences including the end points.

Servicing

Type of servicing

Measure

Adjusting and cleaning

Clean and adjust bearings, sliding points, and power transmission.

For documentation and information purposes, the testing and servicing work as well as the condition

of the system are recorded in a test log book. The test log book must be kept for at least one year or

until the next testing/servicing.

IMPORTANT

The testing and/or servicing interval according to the manufacturer's specification is at least 1

to 2 times a year.

IMPORTANT

The recommended and planned spare parts and wearing parts can be requested from your

service center.

6.2

Door care

The entire system, including the sensors and safety devices, can be cleaned with a moist cloth and

standard commercial cleaners (non-scouring, do not use any solvents). First test the cleaners on a

hidden (not easily visible) place. Keep all guides free of dirt.

NOTICE

It is recommended that for carrying out this work, the operating mode

(Locked) or

(Continu-

ously open) be used, so as to avoid possible injuries from unwanted door movements.

Содержание C 127 SU OFFSET

Страница 1: ...record C 127 SU OFFSET User manual Your global partner for entrance solutions www record group ...

Страница 18: ...4 Technical Data 18 32 BAL_C127 SU_OFFSET_EN_1V0_REC_121 006454770 4 2 Operator in stainless steel casing ...

Страница 32: ...Your global partner for entrance solutions ...