26

Using the Skew Chisel

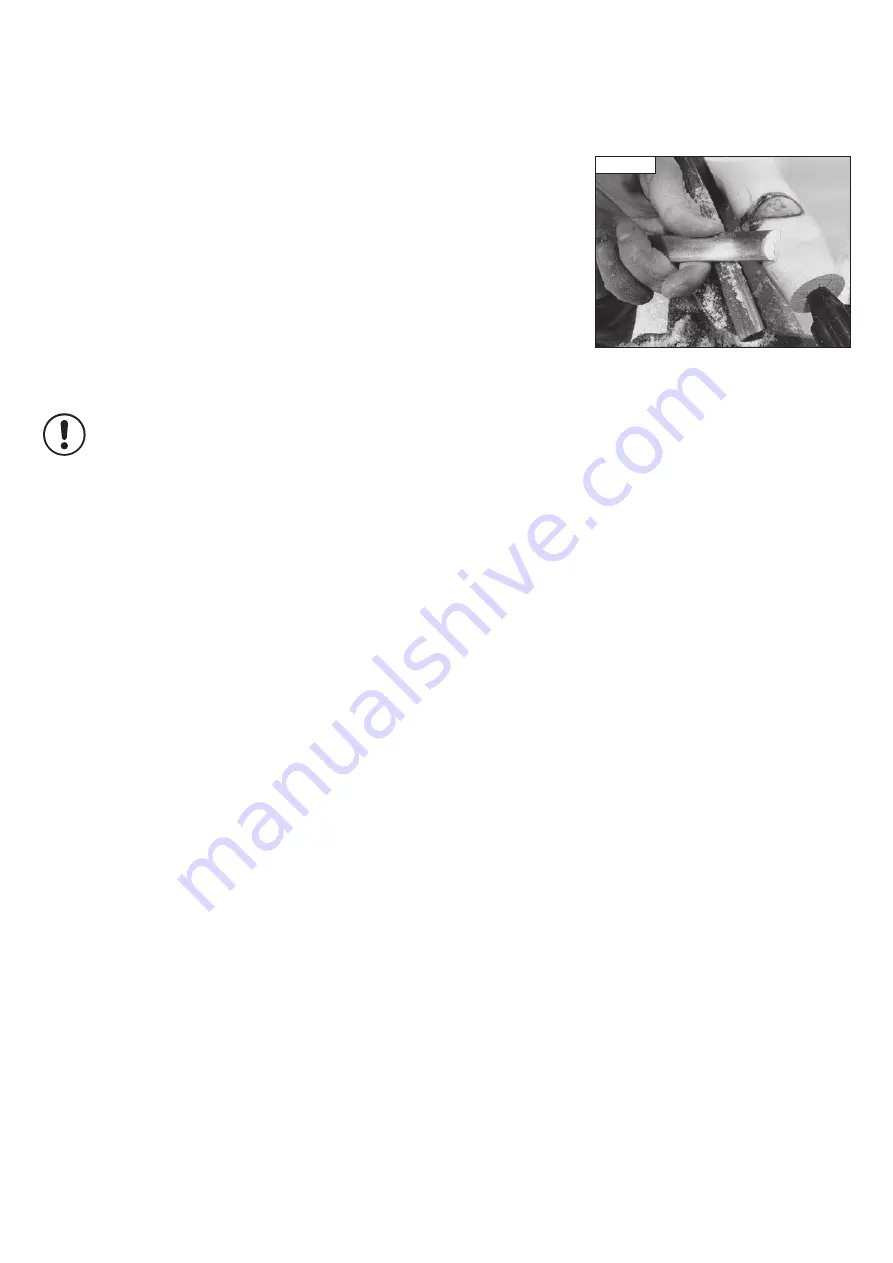

Skew chisels are available in both flat and oval profiles. The curved profile

is favoured by many as it gives better results more easily. Skew chisels are

ideal for creating beads, refining the profiles and can be used to create a

final smooth finish to the workpiece. The skew chisel should be applied

to the workpiece horizontally with the blade resting on the tool rest,

Fig

12.11

, again with the bevel rubbing the workpiece and raising the handle to

take careful, controlled cuts.

Further Operations

The guidelines above give basic instructions on some of the most common

woodturning procedures. There are a wide variety of specialised chisels and

many complementary accessories available for Record Power lathes which

enable a huge variety of work to be created. For further instructions on more

advanced safe and effective woodturning, please seek professional training.

Speeds of the Lathe

To ensure the safest possible use of the lathe, it is important to understand

which speeds are suited to which tasks. In general, the slower speeds should

be used for the initial turning and roughing out of large pieces and the

slowest speed should be used when large pieces are out of balance. This will

reduce the possibility of the workpiece being thrown from the lathe.

Medium speeds are ideally suited for general purpose work which doesn’t

place heavy loads on the spindle of the lathes, for example when creating

the profiles of spindles and some smaller bowl turning.

The fastest speeds should be used only for small diameter work, where

the size of workpiece is relatively small and therefore poses a lower risk

of causing damage. Extra care should be taken when turning at the fastest

speeds, using only a relatively light touch.

When sanding, care should be taken to not burn the operator’s hands or

the workpiece. It is recommended to not exceed the speed used for the last

turning operation. If in doubt, use a slow speed.

12. Intended Use of the Lathe and Basic

Woodturning Instructions

Fig 12.11

i

Kg