28

10.2 Replacing the drive belt

To replace the drive belt simply loosen the tension on the belt using the

tension handwheel. Remove the lower band wheel by undoing the circlip

on the hub. Remove the old belt and fit the new one

Fig.10.4

. Once the

drive belt is in place re-fit the lower band wheel and replace the circlip.

Now tension the drive belt using the tension handwheel. For further

information on tensioning the drive belt please

see section 7.1

.

10.3 The blade guide system

In general usage it is advisable to carefully apply silicon spray to the blade

guides to ensure free movement of the rollers, do not use oil or grease for

lubrication as this will attract dust and cause the rollers to jam. The blade

guide system is a consumable item and depending on usage will wear and

may need replacing.

When replacing components on the upper guide assembly first ensure that

the blade is removed. Undo cap head allen screws

A & B

then remove the

guard,

Fig.10.5.

Once the guard is removed then the various components

can be accessed and replaced. Undo the relevant cap head allen screws

for either the guide rollers or rear support roller

Fig.10.6.

and fit the new

parts.

Once the new components are fitted. The blade should be re-fitted

Section 10.1

and the guides adjusted as shown in

Section 6.

When replacing components on the lower guide assembly first ensure that

the blade is removed. Undo cap head allen screws

C & D

and remove the

guards.

Fig.10.7.

Once the guard is removed then the various components

can be accessed and replaced. The roller bearings are shown in

Fig. 10.7

and the thrust roller bearing at the rear in

Fig.10.8.

This is done by simply

undoing the relevant cap head allen screw and replacing the part. Once the

new components are fitted. The blade should be re-fitted

Section 10.1

and the guides adjusted as shown in

Section 6.3.

Fig.10.4

CIRCLIP

DRIVE BELT

Fig.10.5

Fig.10.6

GUARD

GUIDE ROLLER CAP HEAD ALLEN SCREWS

BLADE SUPPORT ROLLER CAP HEAD ALLEN SCREW

Fig.10.7

Fig.10.8

A

B

C

D

SIDE ROLLER CAP HEAD ALLEN SCREWS

BLADE SUPPORT ROLLER CAP HEAD ALLEN SCREW

10. Maintenance

- cont.

CAUTION!

Before carrying out any adjustments or maintenance ensure

that the machine is isolated and disconnected from the

electricity supply.

i

Kg

i

Kg

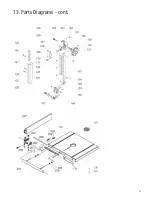

Содержание BS300E Premium

Страница 33: ...33 13 Parts Diagrams cont ...

Страница 34: ...34 13 Parts Diagrams cont ...

Страница 35: ...35 13 Parts Diagrams cont ...