22

8. Operation & Bandsawing Practice

Basic Bandsawing Principles

• The blade cuts on a continuous down stroke.

• Slowly feed the workpiece towards the blade, using only light pressure

whilst letting the blade do the cutting. Always use a push stick and take

care.

• Firmly hold the workpiece and feed it towards the blade slowly, using the

push stick and keeping your hands well away from the blade.

• For best results the blade must be sharp. Damaged or worn blades should

always be replaced.

• Select the correct blade for the job, depending on the thickness of the

wood and the cut to be made (see blade selection).

• For straight cutting use the rip fence supplied.

• When cutting shapes, follow the design marked out by pushing and

turning the workpiece evenly. Do not attempt to turn the workpiece

without pushing it, as this may cause the workpiece to get stuck, or the

blade to bend.

Always ensure that your machine is properly maintained and clean. Before

commencing work on an important project, it is advisable to familiarise

yourself with the operation of the equipment by practising on low value or

scrap materials.

Complicated Cutting

Very complicated cuts and small radius curves are the best accomplished

with the aid of pre-drilled holes combined with a few tangential or radial

cuts. This technique will achieve excellent results without putting undue

tension on the blade and blade guide assembly.

CAUTION!

Particular care should be taken towards the end of the cut as

there will be a sudden decrease in resistance and care must be taken to

stop hands from being thrown towards the blade. Always use a push stick.

i

Kg

Restarting

In the Event of a Blockage or if the Machine Stalls

If the bandsaw stalls due to the blade becoming trapped in the work piece,

switch it off immediately by pressing the emergency stop button and wait

for the machine to come to a complete stop before proceeding further.

If the blade is trapped within the work piece, it may be necessary to prize

the work piece apart slightly using a suitable lever in order to free the

blade. If it is not possible to free the blade using this method, then it may

be necessary to cut the blade using suitable side cutters or tin snips.

Replace the blade if necessary and ensure that it is correctly tracked and

tensioned and that both doors of the bandsaw are fully closed and secured

before attempting to re-start the machine.

To re-start the machine, press the green button marked ‘I’ on the switch.

In the Event of a Power Failure

The bandsaw is fitted with a no volt release (NVR) switch to protect the

user against automatic starting of the machine when power is restored

after a power failure.

In the event of a power failure, first locate and rectify the source of the

failure. If the fault is within the power circuit of the workshop, there may

be an underlying cause (circuit overload etc.) that should be investigated

by a qualified electrician, before attempting to restore the power source.

If a cutting operation was taking place when the power supply was

interrupted, then it may be necessary to free the blade from the work piece

before attempting to re-start the machine.

Once the power is restored, the machine can be re-started by pressing the

green button marked ‘I’ on the switch.

Blade Selection (TPI)

The selection of the best blade configuration (see the table below) is

necessary for optimum cutting performance.

• Correct blade choice is primarily dependant on two factors: material

thickness and material type.

• Greater TPI should be selected as material thickness decreases.

• However, if the TPI is too great, the tooth loading will be insufficient

to enable penetration; and cutting. The teeth will also rapidly lose their

sharpness.

• For thicker material a lower TPI should be used otherwise the gullet will

not be sufficient to clear the waste and the blade will stall or burn the

wood.

• In general a minimum of 3 teeth should be in contact with the wood at

all times during cutting.

The accompanying blade selection chart (see the table below) gives

guidance on the TPI that should give the best results when cutting a variety

of material types and thickness. The table below provides recommendations

on selecting the correct blade for a variety of commonly used materials. If

in doubt about any aspects of blade selection contact

Customer Services in

your country.

The table provides a guide to selection only. Exact tooth configurations

are not always available, nor are all blade configurations covered, but the

principles remain the same. For special applications, custom blades can be

supplied please call Customer Services in your country.

WARNING!

In circumstances such as cutting deep or wet timber,

the work piece may close up behind the blade causing it to stall. In

the event that the blade stalls whilst cutting, ease the work piece

backwards slightly, to release feed pressure from the blade. Allow the

blade to reach full speed before continuing to feed the work piece in

to the blade. If the blade fails to move when feed pressure is released,

immediately switch off the machine and disconnect the power supply

before attempting to free the blade from the work piece.

WARNING!

If any component of the machine fails whilst in use or

if the blade should break whilst the machine is running, immediately

switch off the machine and disconnect from the power supply. Remove

the faulty component and replace only with genuine Record Power

replacement parts. Any electrical components should only be replaced

by a suitably qualified person. To replace a broken blade, please refer

to the section of this manual entitled “Band saw Blade Set Up”.

Always remember to fully release the blade tension mechanism before

attempting to fit a new blade. If you are in any doubt about using the

machine following a failure or if you need to order replacement spare

parts or blades, please contact Customer Services in your country.

i

Kg

i

Kg

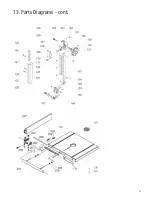

Содержание BS300E Premium

Страница 33: ...33 13 Parts Diagrams cont ...

Страница 34: ...34 13 Parts Diagrams cont ...

Страница 35: ...35 13 Parts Diagrams cont ...